by OpGo | Apr 11, 2023 | Deburring, ISO Finishing

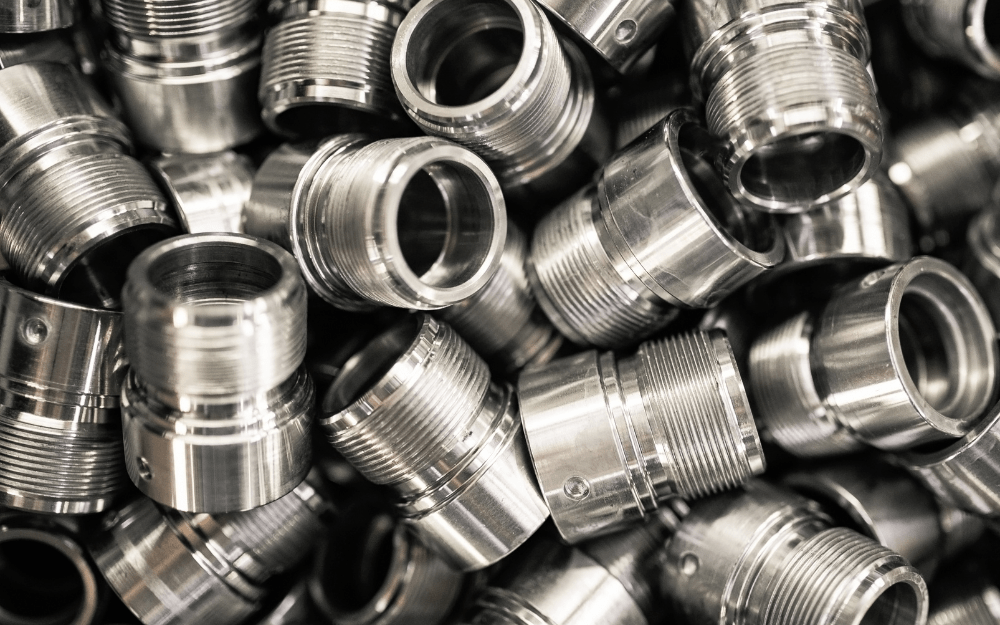

Mass finishing is becoming an essential process in modern manufacturing and can significantly improve the quality of your products. By using mass-finishing techniques, manufacturers can produce high-quality products that are quick and cost-effective. Let’s...

by OpGo | Jun 6, 2022 | ISO Finishing

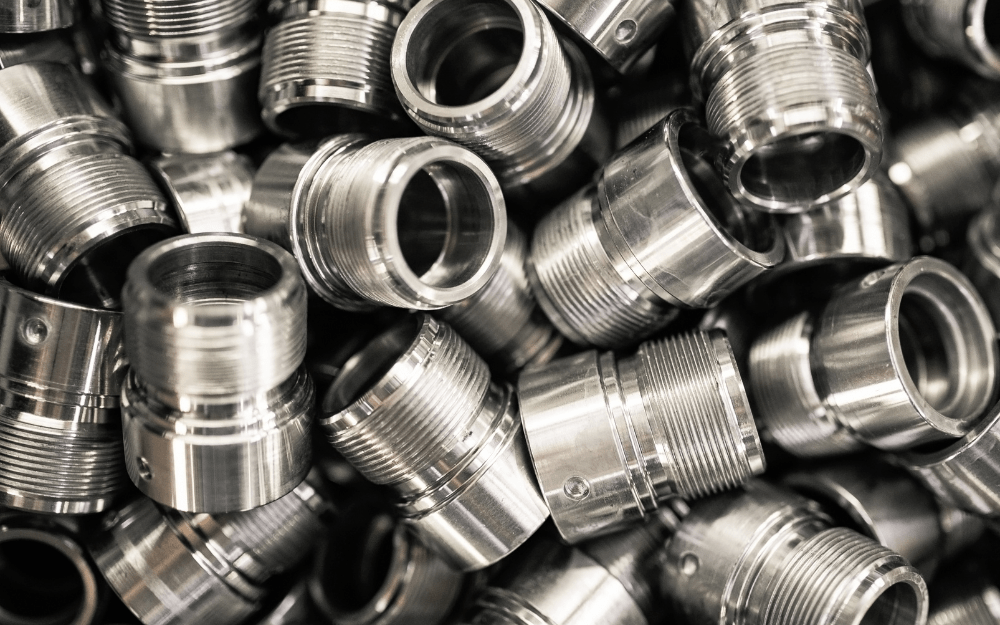

Media choices play a significant role in the properties of each alloy and how it affects them during the finishing process. Media is commonly used for vibratory tumbling and produces an altered appearance or finish to another material or part to meet exact finishing...

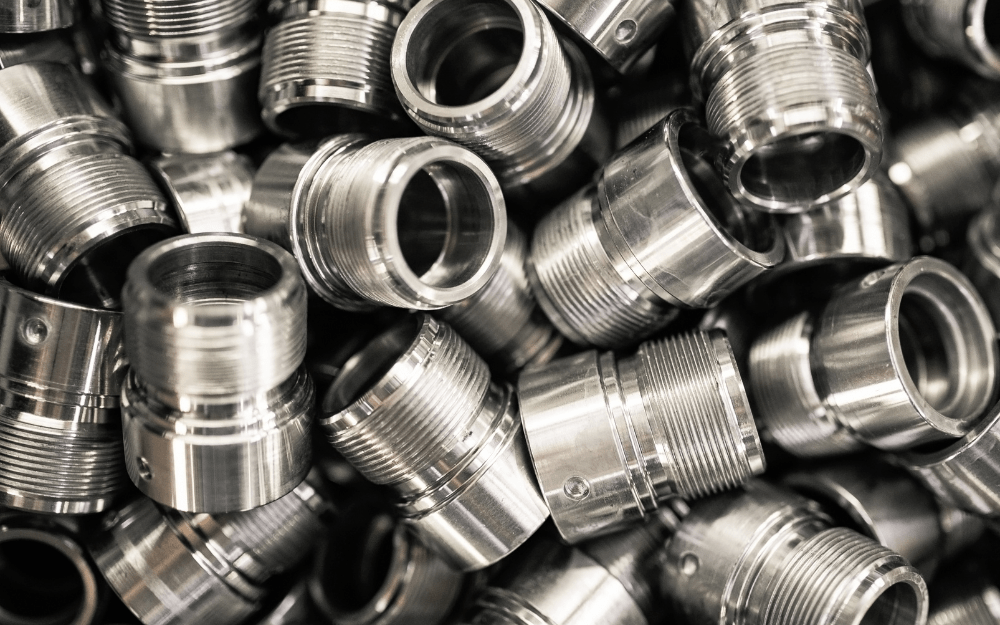

by OpGo | May 18, 2022 | Automotive, ISO Finishing

The success of the automotive and motorsports performance industry can be attributed to the Precise finishing of what is under the hood. Metal automotive parts, specifically worm screws and worm gears require a specific type of surface finishing to ensure they...

by OpGo | May 14, 2021 | ISO Finishing

It’s not often that Mike Klein of ISO Finishing gets a call from an artist but as soon as Roger Fowler mentioned that he sculpts fish out of metal, Mike was hooked. As Roger went on to explain, he’s a lifelong fly fisherman and art enthusiast. Several decades ago, he...

by OpGo | Apr 7, 2021 | Additive Manufacturing Finishing, ISO Finishing

Additive manufacturing is an innovative manufacturing process that creates 3D printed objects. As the name suggests, material is only added when and where it is necessary. Parts are created using computer-aided-design (CAD) software or 3D object scanners to deposit...

by OpGo | Jul 23, 2020 | ISO Finishing, Medical

Surface polishing plays a vital role in the performance of parts in a variety of industries, especially when it comes to orthopedic part polishing. From aviation and aerospace to performance motorsports, surface polishing influences how well parts perform. While...