With each orthopedic part having its own unique surface finishing requirement, the performance of polished parts play a critical role in performance within the medical industry. Finishing specialists must meet the appropriate requirements not only for certification standards but also to ensure patient’s safety. Corrosion resistance and sterility of orthopedic parts is vital to a patient’s recovery and quality of life. No matter how well a component is designed and manufactured, there is a risk of corrosion during the manufacturing process. Our documented processes avoid the risk of parts carrying bacteria or other debris.

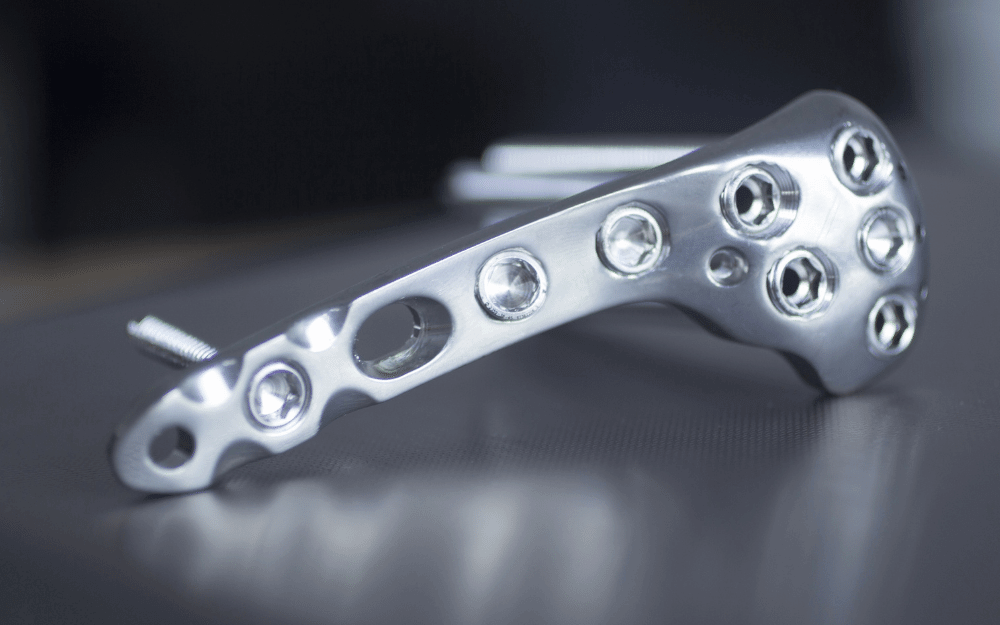

Surface finishing requirements for orthopedic parts (dental implants, shoulder joints, knee and ankle joints) require special equipment and techniques that vary in complexity. At ISO Finishing, we understand the importance of each detailed step that goes into the polishing process of orthopedic parts and implants.

- Start with the right equipment to accommodate technical requirements

- Remove imperfections left over from previous processes in part development.The removal of sharp edges and burrs prevents rupturing blood vessels and blood clots during implantation and the healing process

- Adapt methods for special material, geometries and sizes

- Prepare surface for buffing for a mirror finish

- Ra readings of < 1.0 micro inches

- Document a process that is reliable and repeatable for mass production

Providing Value and Expertise for Orthopedic Components

ISO Finishing has extensive experience in the polishing for medical manufactured parts. Our market-leading approach to surface refinement allows us to process various medical grade materials like; titanium, cobalt chrome, stainless steel, silicone and polymer alloys.

ISO Finishing specializes in vibratory finishing, high energy polishing, and micro-precision surface finish improvement. Through our innovative finishing solutions and industry leading delivery times, ISO Finishing has become the go-to finishing resource for medical device manufacturers. Some of the most renowned medical device manufacturers rely on our expertise.

Our team has extensively developed and documented our processes to ensure each finished orthopedic part meets their specified requirements. High-quality surface polishing is a crucial step in the manufacturing process for medical components.

Our areas of specialized surface improvement include:

- Medical instruments

- Orthopedic implants

- Knee and hip replacements

- Bone screws and plates

- Catheters and reattachment buttons

- Surgical support items including: Handles, trays, hooks, clamps, drill bits, and drill guides

Surface Finishing with Patient Outcome in Mind

Technological advances have allowed for life changing breakthroughs in the medical device manufacturing field. Every step we take during the finishing and polishing process ensures that each piece is in optimal condition for every scenario.

With patient outcome in mind, our team focuses on production efficiency, dimensional accuracy, and high-performance. Mass finishing provides the perfect solution for creating a superior surface functionality for any orthopedic component.

Why Choose ISO Finishing Surface Polishing for Orthopedic Parts and Implants

Custom development strategy

It is all about precision. We customize each finishing process to fit our clients’ needs from start to finish. Our valued relationships with medical manufacturers and extensive expertise allow us to be a true value-added solution in passivation services to our customers’ finishing needs. Our certified processing is documented and designed to ensure each finished part exceeds the most demanding requirements.

Consistent quality you can always count on

There is no room for error when it comes to polishing orthopedic parts and implants. Our specialized mass finishing is extremely consistent. Consistency is a must for any surface polishing but especially important when finishing medical parts and implants. Dimensional accuracy, component production efficiency, and high performance surface polishes have become a medical engineering requirement.

Mass finishing technology has played an essential role in delivering consistent quality surfaces to orthopedic components, medical instruments, implants, and pharmaceuticals. ISO Finishing has developed proven finishing processing results that contribute to the life cycle of medical device manufacturing.

For more information about surface finishing for orthopedic parts and implants, contact us today.