by OpGo | Apr 11, 2023 | Deburring, ISO Finishing

Mass finishing is becoming an essential process in modern manufacturing and can significantly improve the quality of your products. By using mass-finishing techniques, manufacturers can produce high-quality products that are quick and cost-effective. Let’s...

by OpGo | Feb 1, 2020 | Deburring, ISO Finishing

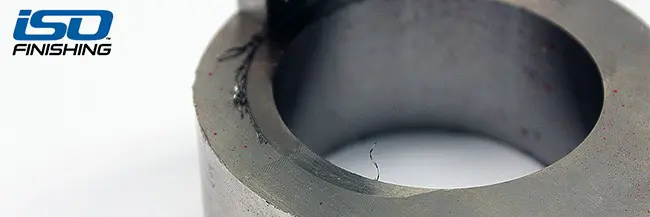

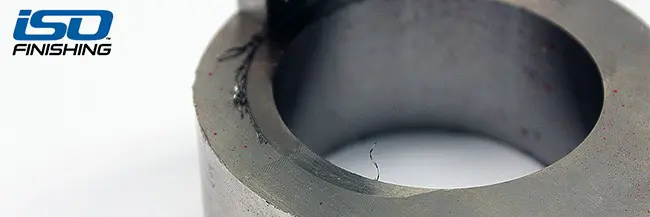

Burrs, which are a ridge or area of roughness, typically occur when the material used to create the part is cut, or pieces of the material are removed. Methods such as welding, molding, casting, and shearing tend to cause sharp, bumpy edges that affect part...

by ISO | Nov 1, 2018 | Deburring, ISO Finishing, Isotropic

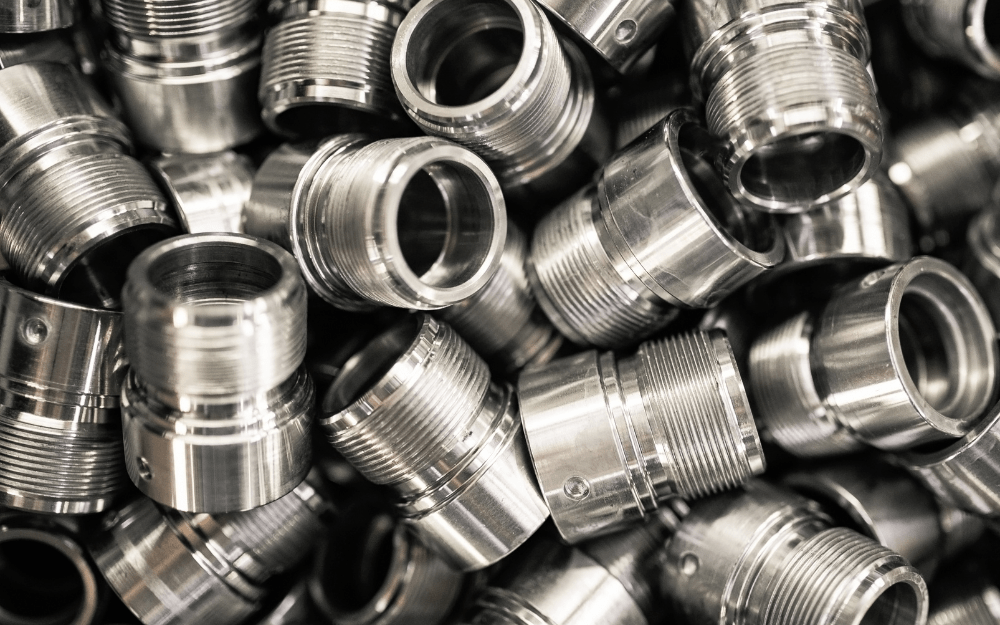

Saving Time with Machine Surface Finishing At ISO Finishing, it’s about saving time without sacrificing surface quality. Deburring of parts and finishing of machined components used to be a manual process, but technology has automated the process, allowing for...

by ISO | Jun 28, 2018 | Deburring, ISO Finishing, ISO Resources

Why is Surface Roughness So Important in Manufacturing? Surface roughness is a component of surface texture and plays an important roll in determining how an object will interact with its environment. Roughness is a good indicator of the performance of a mechanical...

by ISO | Jun 28, 2018 | Deburring, ISO Finishing

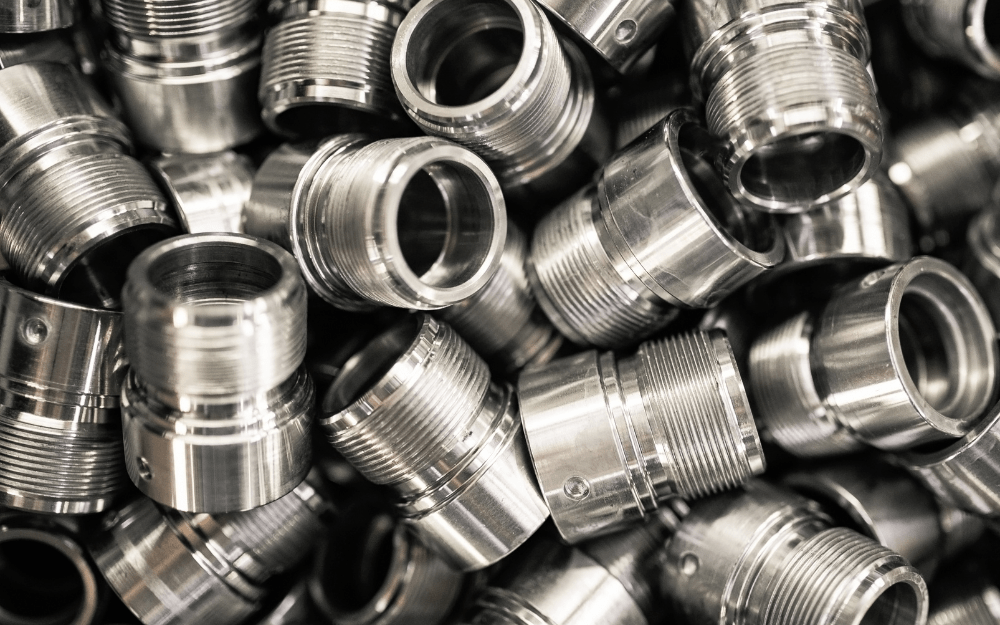

ISO Finishing’s skilled engineers and technicians have the experience and expertise to determine the most effective process for the specific type of finish your parts require, but what is mass finishing and how does it relate to deburring? The act of deburring is...

by ISO | Jun 28, 2018 | Deburring, ISO Finishing

Yes, there are ways to prevent burrs. The first consideration should be to identify what is causing the burrs to form. If the burr isn’t caused in the first place, you don’t need to remove it. That isn’t always possible. If preventing burrs from forming isn’t a...