AUTOMOTIVE CRANKSHAFT POLISHING

Performance Motorsports |

Deburring, Polishing

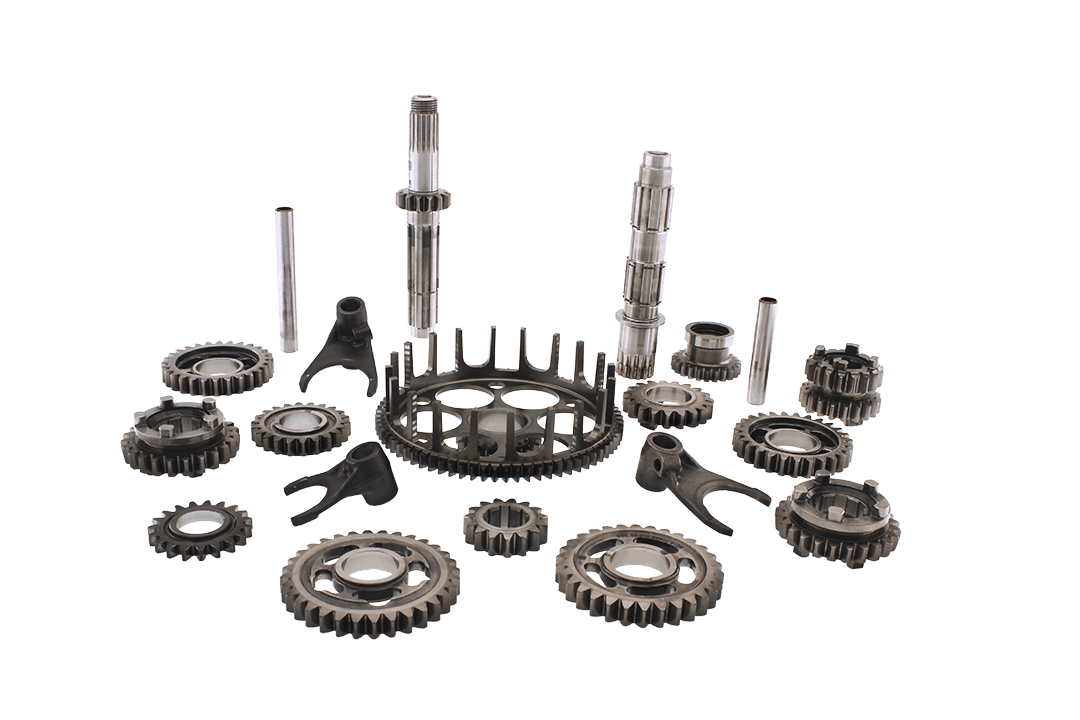

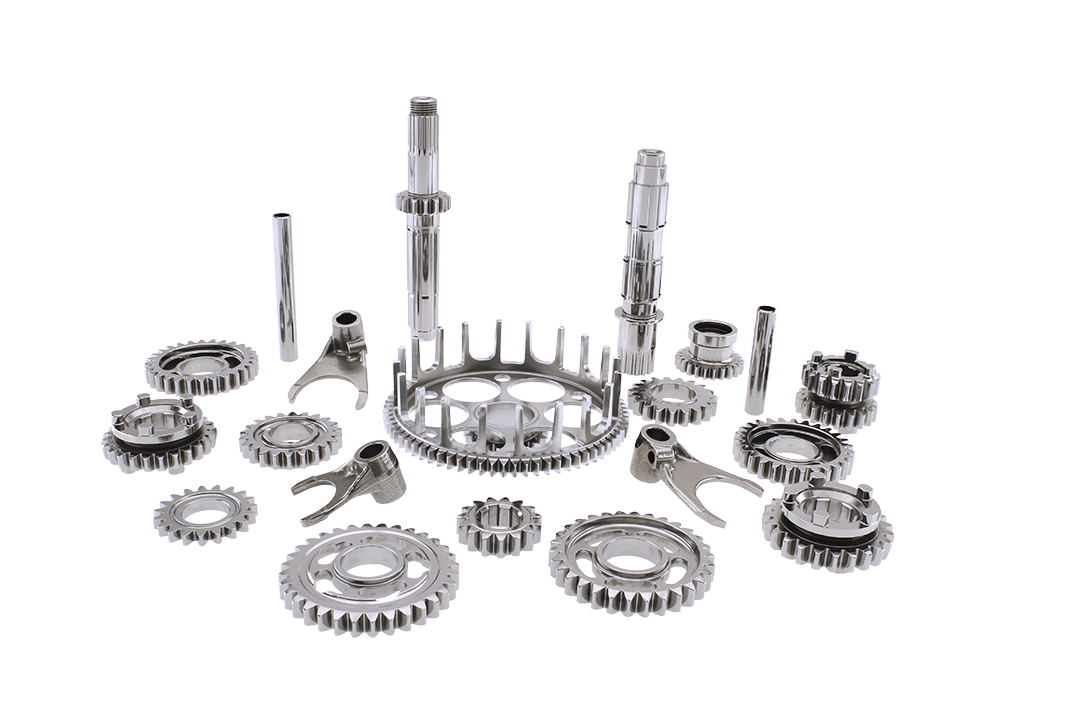

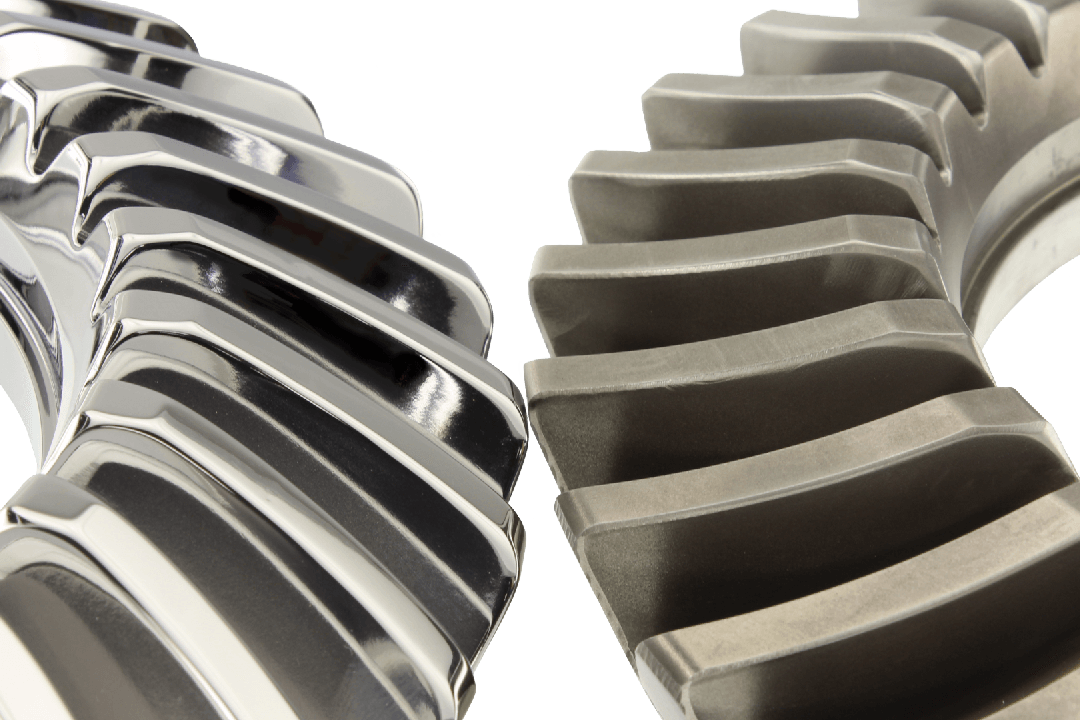

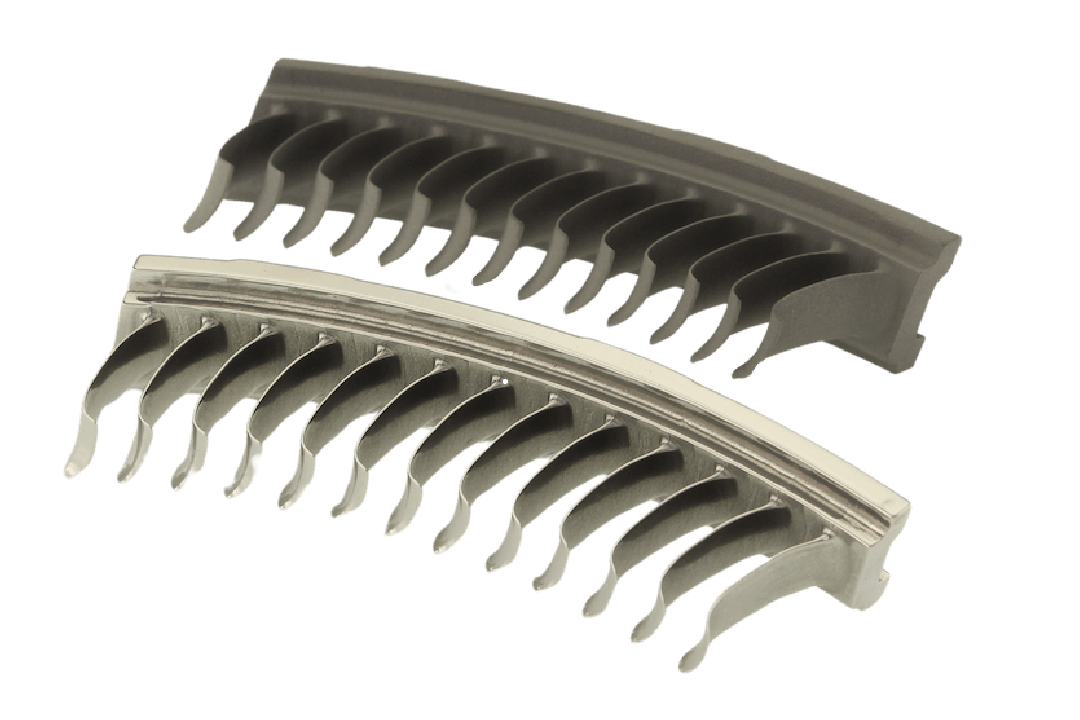

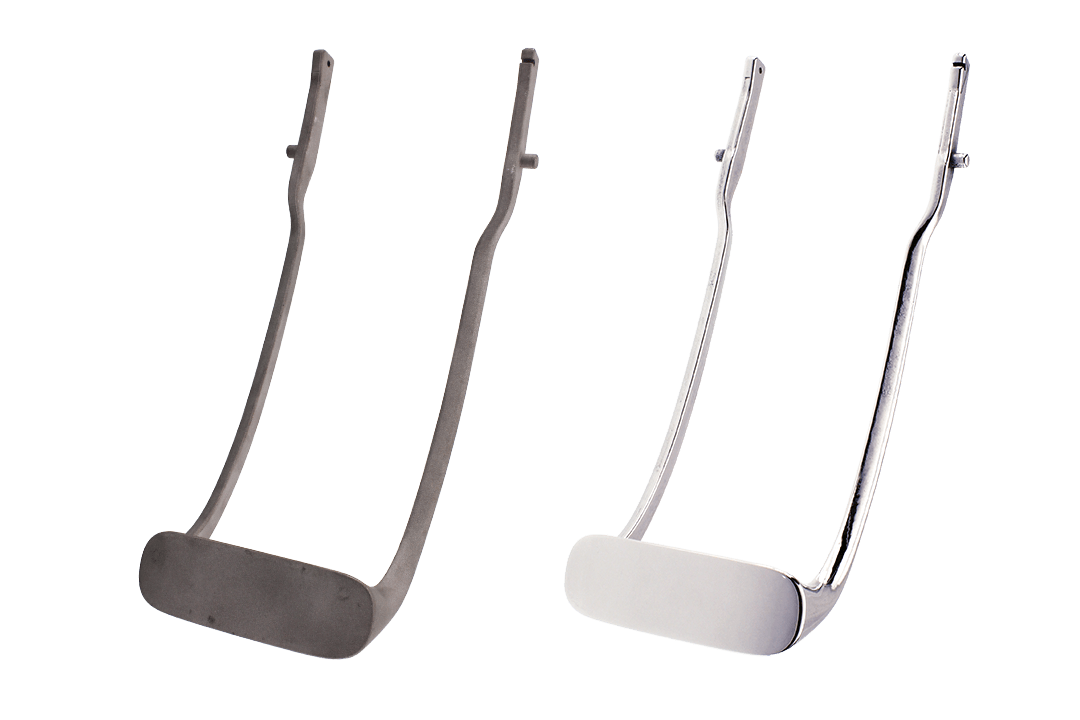

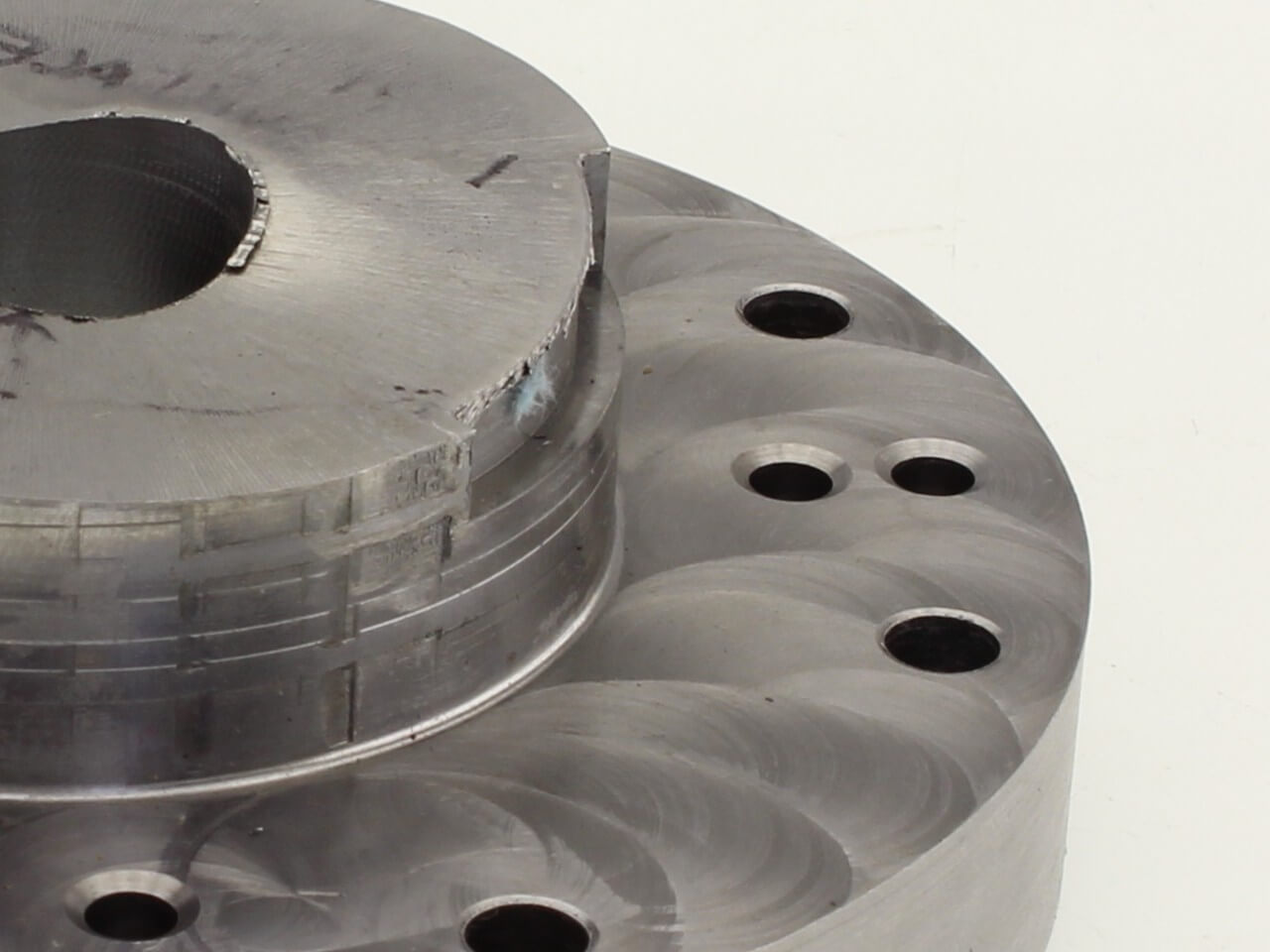

This KTM performance dirt bike transmission was brought to ISO Finishing by a custom bike builder with a simple request to have all parts deburred and polished. The final polish consisted of a micro cross-hatch finish which increased smoothness of shifting without increasing heat output.