HZ Series Centrifugal Barrel Finishing (CBF)

ISO Finishing is a proud distributor of MFI Centrifugal Barrel Finishing Systems. The HZ Series CBF systems are among the fastest and most economical centrifugal barrel finishing machines available. These centrifugal barrel finishing machines are the industry mainstay when it comes to polishing, deburring and deflashing parts. From helicopter rotors in the aerospace industry to orthopedic implants and surgical instruments in the medical device manufacturing industry, these tumbling machines are a versatile, money-saving solution for polishing and deburring. In a matter of minutes a barrel machine can clean up metal, acrylic or rubber parts and have parts finished in what could take hours or even days by hand. The surface finish achieved by these machines is isotropic, meaning parts are polished uniformly and evenly, something that simply cannot be achieved by hand in such a short amount of time.

How does a Centrifugal Barrel Finishing Machine work?

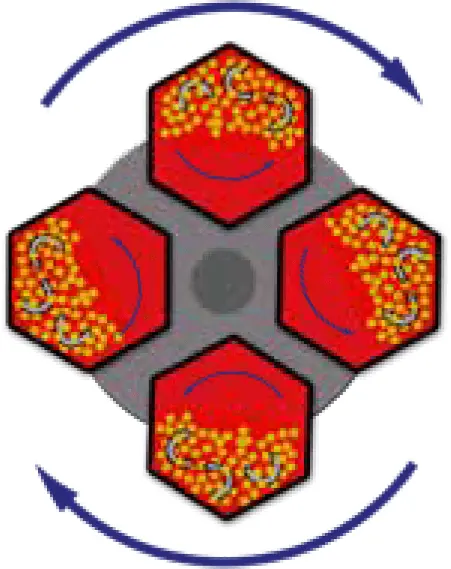

In the Centrifugal Barrel Finishing process four hexagonal barrels are mounted at the periphery of a large planetary turret.The barrels are loaded with parts, media, compounds and water to a volume of 50-90%. During operation the entire drum of the deburr tool rotates like a Ferris wheel. Rotation of the large turret creates a centrifugal force on the media and parts inside each barrel. As the speed increases,  the media and parts rub against one another randomly and repeatedly, removing even the smallest imperfections. In a matter of minutes the finishing cycle is complete and the parts are ready to be separated from the media.

the media and parts rub against one another randomly and repeatedly, removing even the smallest imperfections. In a matter of minutes the finishing cycle is complete and the parts are ready to be separated from the media.

Leveraging the increased G force allows cycle times to be up to 30 times faster that conventional vibratory methods. Adjusting the load, speed, media and cycle times make Centrifugal Barrels one of the most versatile finishing tools available. Results with centrifugal barrel finishing machines are consistent and predictable, every time.

Very fine finishes can be developed with the use of centrifugal barrel finishing machines. These types of finishes are useful not only in the aesthetic sense but produce functional surface effects that can help parts last longer and perform better.

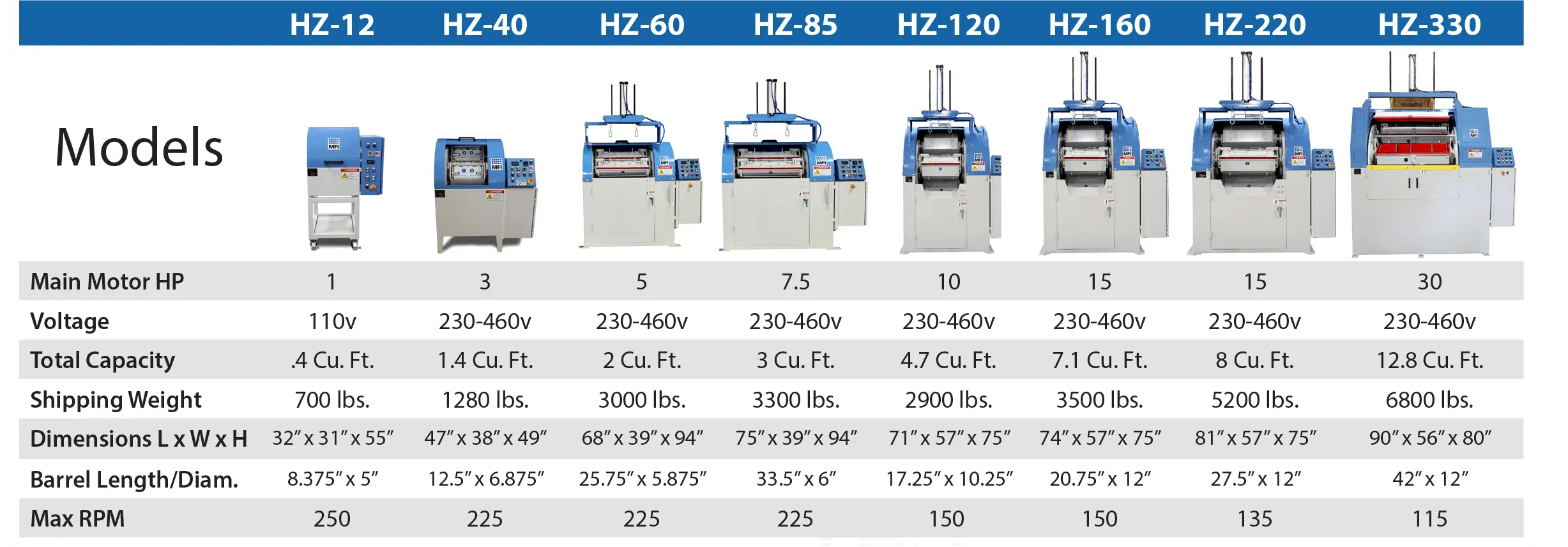

Centrifugal Barrel Finishing Machine Sizes

CBF Machines available from ISO Finishing vary in size from the compact, table-top HZ-12 to the super-sized HZ-330. No matter the size, these machines are built for heavy use with industrial ball bearings and hot poured polyurethane barrel liners that can stand up to wear of running repeated finishing cycles.

Entry-Level Centrifugal Barrel Finishing Machines

The HZ-12 and HZ-40 models make-up the compact line of CBF machines. They feature smaller, removable barrels. The HZ-12 is popular in the dental industry because of its smaller stature. It works well in small places like dental labs, and packs the same high-end finishing punch of its bigger brothers. By purchasing a second set of four barrels, the operator can run one set of barrels while they are loading and preparing another. This can dramatically reduce downtime on the machine. Download Entry-Level Machines PDF

Mid-Size Centrifugal Barrel Finishing Machines

The HZ-60 and HZ-85 provide more than double the capacity and efficiency over the smaller tumblers. Each machine features a wide barrel that can be divided into several chambers to aid in avoiding part impingement. Download Mid-Size Machines PDF

Full-Size Tumbling Machines

From the HZ-120 with its stout and long barrels to the HZ-160, these full sized industrial finishing machines can handle just about any type of part imaginable. The HZ-160 features a 15 horsepower motor with 1.5 more cubic feet of barrel space than the HZ-120. For jobs that require a bigger barrel or a greater overall volume, the HZ-160 offers a great solution. These CBF machines can be fully customized with a touchscreen control panel, barrel lid-lifting system, parts separator, drain pan and infrared safety curtain. Download Full-Size Machines PDF

Super-Sizes Tumbling Machines

The HZ-220 CBF Machine is a significant jump in size. With barrels that are over two feet wide, this machine can handle larger parts and volume. The HZ-330 is a monster of a machine that has been used a variety of select applications. Download Super-Size Machines PDF

We All Get Distracted

by Shiny Objects

Send a few samples and we will show you a perfect surface finish.

There’s nothing to lose and your part finishing will get you noticed.

ISO Finishing Precision Processes

Custom Development Strategy

There is no magic here—it’s precision. We customize each finishing process to fit our clients’ needs from start to finish. At the end of the day, we specialize in you. Our centrifugal barrel services are ideal for parts from 3mm³ to up to 9” x 9” x 28” and are custom tailored for each specific component.

Samples & Quality

We formulate a process for each product and provide our clients with finished samples at no charge. Collaboration with the customer is key. If something needs improvement, we’ll use the client feedback to adjust the process—not the standard. The result is a customized, consistent, and repeatable set of specifications for finishing your unique product.

Advanced Technology

We continue to add state-of-the-art machinery, media and inspection equipment to adapt to the industry’s latest advances. Our methods have exceeded expectations by providing a better finishing quality and faster turnaround times than are typically possible in-house or as an outsourced operation.

ISO Finishing is the experienced and ideal finishing partner for manufacturing and component manufacturing companies. We simply produce the best surface finishes in the industry. To learn more information or for free sample processing, contact us at 1-844-623-7998.