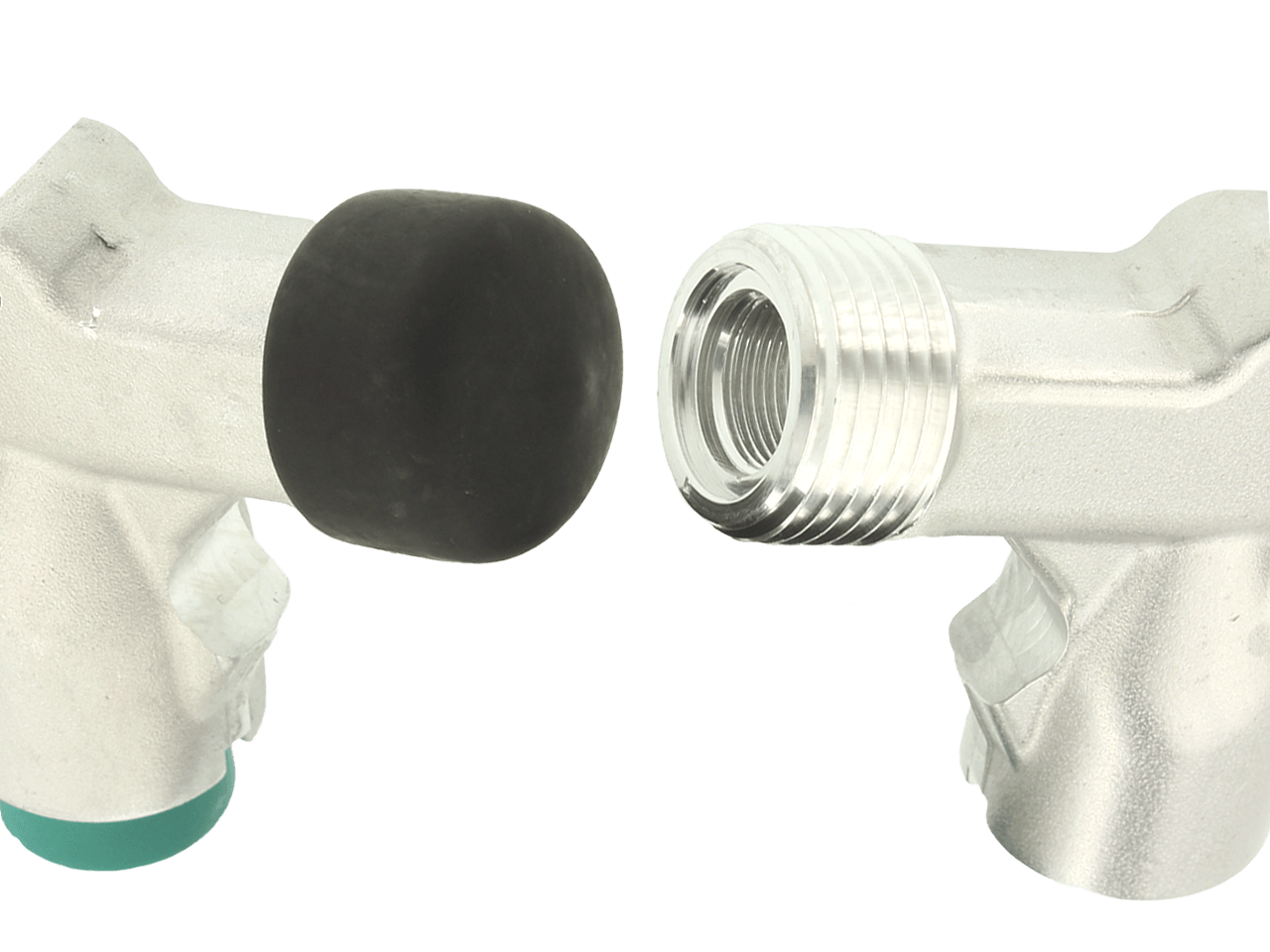

Precision masking is used to protect delicate part features during centrifugal barrel finishing (CBF) processes such as polishing, deburring, descaling and deflashing.

Parts, features and finishing requirements are assessed prior to processing masked may be used for multiple reasons. Masking may be internal, external and/or a combination of both. Reasons for masking include:

Custom masks are developed when standard plugs and caps do not properly fit parts with custom threads, unique part geometry, non-standard part features, or proprietary shapes. The ISO team is experienced in creating custom solutions when other options do not fit.

Masking applications are unique to each project and are determined by the needs of the customer, a part’s material, and the specific areas that do/do not require finishing. A mask may be applied to the exterior first, then the interior or vice versa. There are instances when masking is used during the first phase of finishing and removed prior to subsequent phases.

ISO Finishing is an expert in creating micro-precision surface improvements that are documented and repeatable for parts in any material with unique part geometries, features and shapes.

Let us show you how our finish will become your finish by processing your sample. Let us show you what we can do.

LET’S GET IT FINISHED.