Every production process has an impact on surface roughness through the creation of irregularities in the surface. In metrology, the finest, or shortest wavelength deviations are referred to as surface roughness. These irregularities directly impact the performance and longevity of mechanical components.

As a part of the design process, surface roughness symbols communicate and specify the required surface roughness and the efficiencies to be made during the production process. Testing is done to ensure the requirements are met.

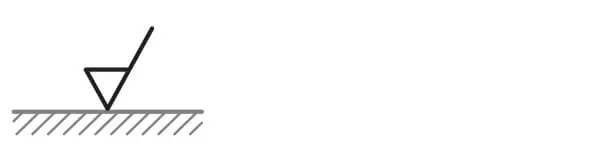

Below are common roughness symbols used in the design process which are specified on a product’s drawing or print.

Surface texture obtained by any manufacturing process (e.g., turning, grinding, plating, bending)

Symbol indicating a surface the requires a removal process and allowance indicated. Surface texture obtained by material removal by machining Operation (e.g., turning, drilling, Milling, slotting)

Symbol indicating a surface where removal processes are prohibited.

Symbol indicating a grain direction (lay).

Examples indicating the Ra upper limit.

Example positions of Symbols

To learn more about Surface Roughness Symbols, click here.

To meet the requirements specified in a print, the surface roughness must be measured using specialized equipment such as a profilometer or interferometer. Surface roughness measurements are taken in the transversal direction to the lay.

The mean arithmetical value of a surface roughness profile defined on a sampling length is represented as a numeric value, Ra. Ra is typically measured in µm (micrometers) or µin (microinches) depending upon the standard used. The Ra value of the surface roughness profile indicates whether the required finish has been met.

Some level of surface finishing is typically required to remove burrs, flash or tooling marks created during production to meet the value specified in a print. The more complicated the shape of the surface, the more precise the surface finishing must be.

ISO Finishing is an expert in creating precise, documented and repeatable surface finishing solutions which meet the strictest requirements. Let us show you first-hand how our finish will come your finish by processing your sample. Let us show you what we can do.

LET’S GET IT FINISHED.