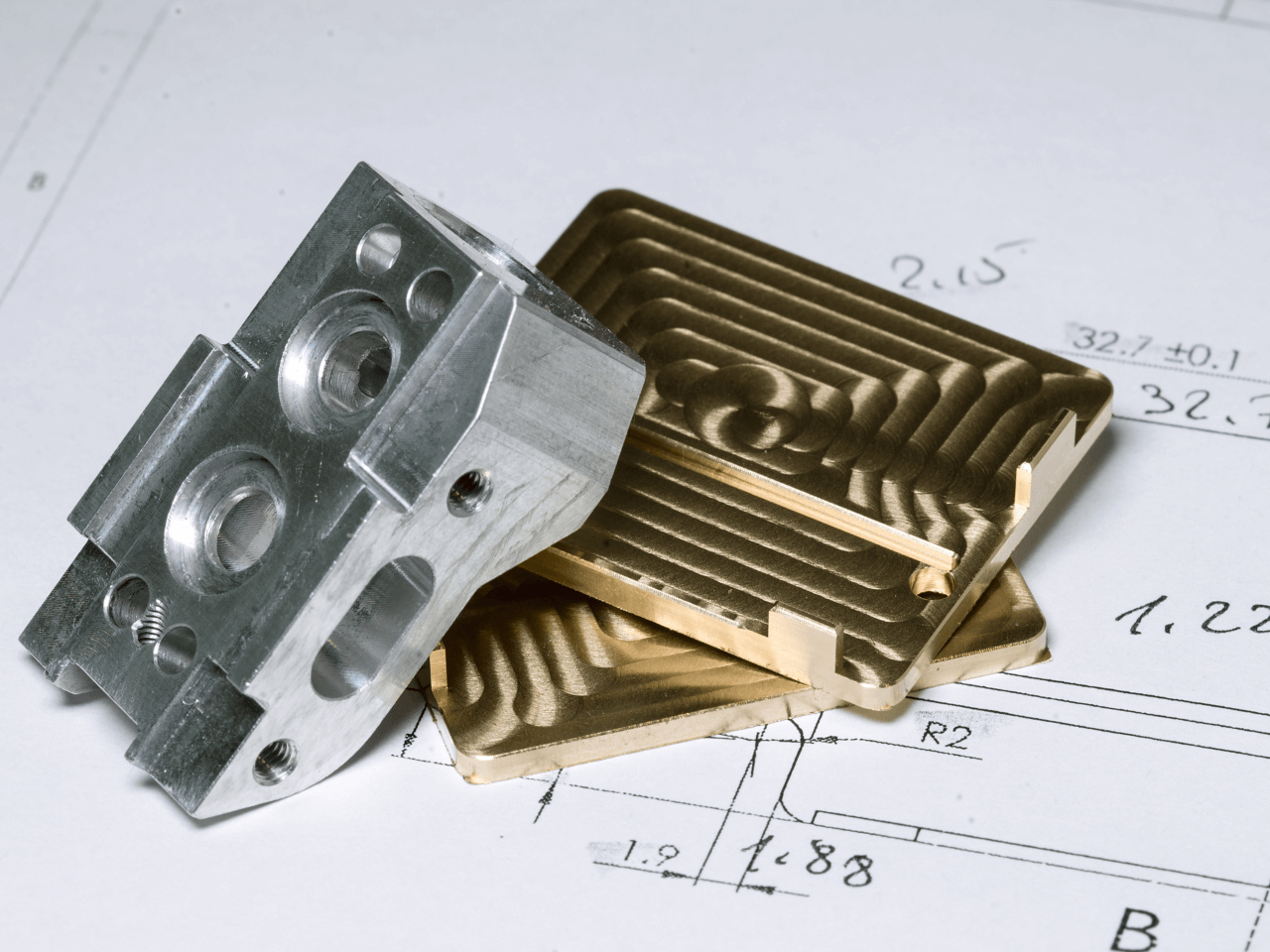

Surface texture refers to the deviations in surface topography characterized by different properties such as form, waviness, roughness and flaws. While all of these properties impact a product’s performance, surface roughness is the direct result of the material condition and production process used. Surface roughness is a good indicator of how a mechanical product will interact with its environment and its performance.

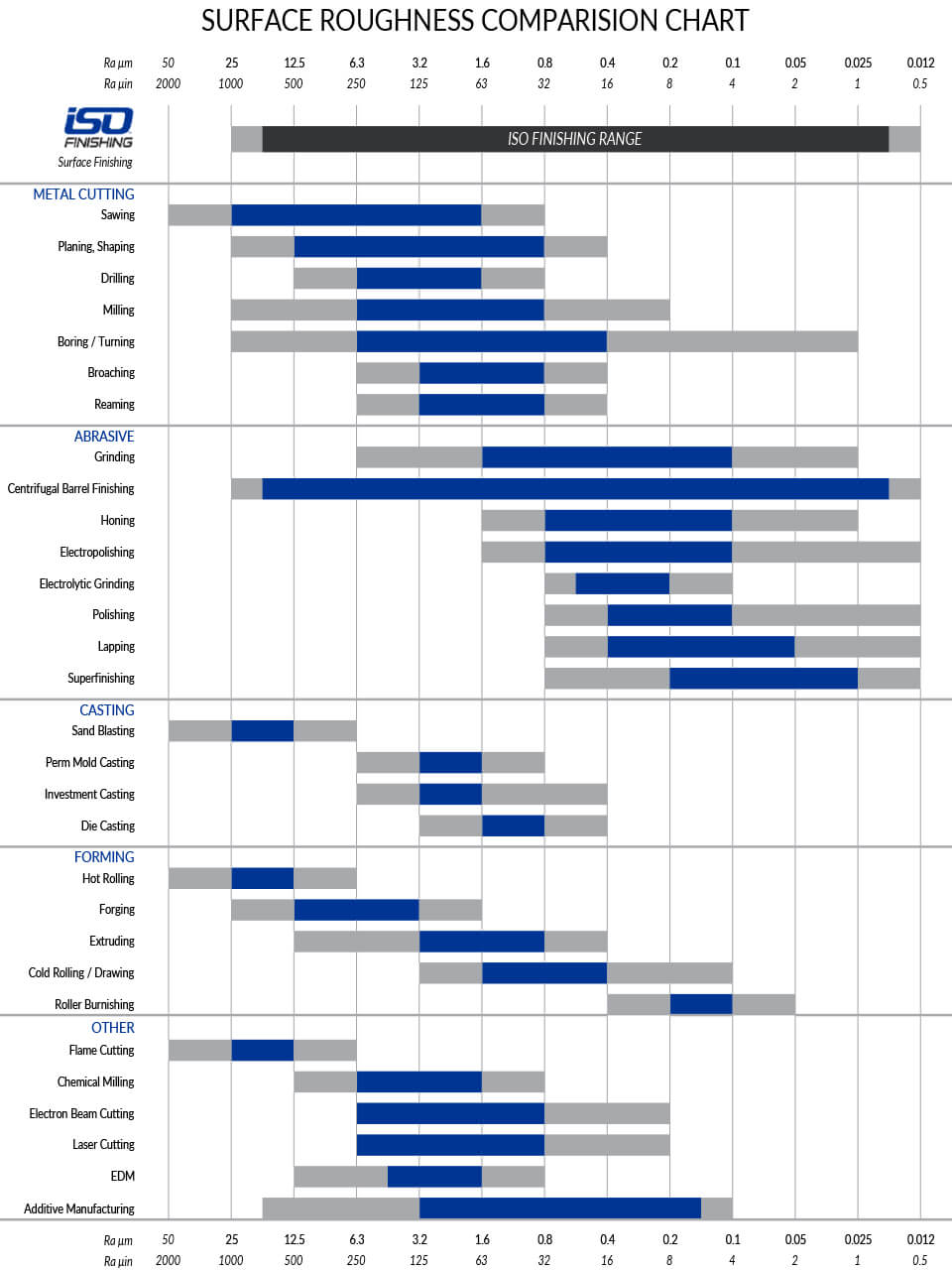

There is a wide range in the variations of surface roughness and edge condition depending upon the production process used. Listed below are common manufacturing techniques with their corresponding standard Ra values and the typical Ra value ISO Finishing can achieve following surface finishing.

ISO 9001:2015 certified and FFL licensed, ISO Finishing is an expert in creating customized, documented and repeatable isotropic surface finishing processes. We are experienced in working with all material types and our surface finishes meet the strictest requirements.

The best way to show you first-hand how our finish will be your finish is to process your sample. Let us show you what we can do.

LET’S GET IT FINISHED.