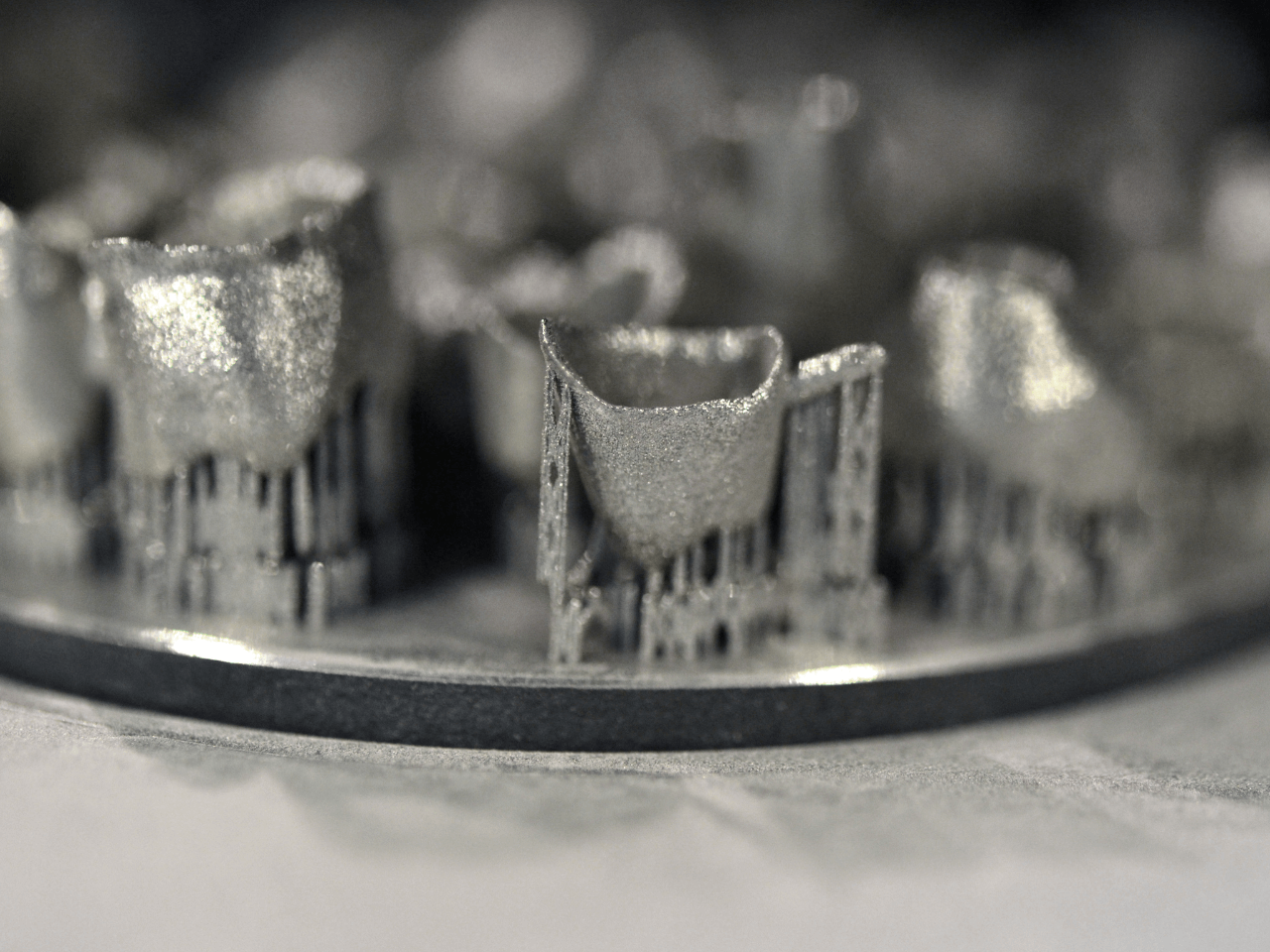

Additive manufacturing (AM) is an innovative manufacturing process that creates fully functional 3D printed parts. As the name suggests, material is only added when and where it is necessary. Parts are created using computer-aided-design (CAD) software or 3D object scanners to deposit material one layer at a time in precise geometric shapes. Parts can be printed in a variety of materials, though the three most widely utilized are polymers, ceramics, and metals.

The additive manufacturing process utilizes different 3D printing techniques such as:

Quickly and efficiently producing parts using a repeated process, 3D printing offers a timely and cost-effective approach to manufacturing. Its speed and low cost are ideal for producing low-volume, high-complexity, and ever-changing parts. The simplicity of the process makes the development of complex parts easier, less expensive and more precise.

Additive manufacturing serves a wide range of applications. Recognizing the many benefits of 3D printed parts, researchers have continued to find ways to utilize the process to create solutions across countless industries.

The medical industry relies on AM to create custom ankle replacements and other orthopedic implants. Likewise, the military and defense sectors used 3D printing technology to print critical replacement parts while in the field or at maintenance depots. AM also streamlines various processes, such as tool fabrication, research and development and rapid prototyping.

Surface finishing is an excellent complement to the AM process and is necessary for products requiring a smooth surface, precise edges or preparation for coating. The type of service finishing and media used will depend greatly on the material, shape, and size of the printed part. The result is enhanced surface quality, geometrical accuracy and improved part performance.

ISO Finishing provides a range of finishing services for additive manufactured and 3D printed components. Our proven process makes us the ideal partner for additive manufacturers in a wide range of industries. Let us process your sample so you can see first-hand how our processes can improve your products. Let us show you what we can do.

LET’S GET IT FINISHED.