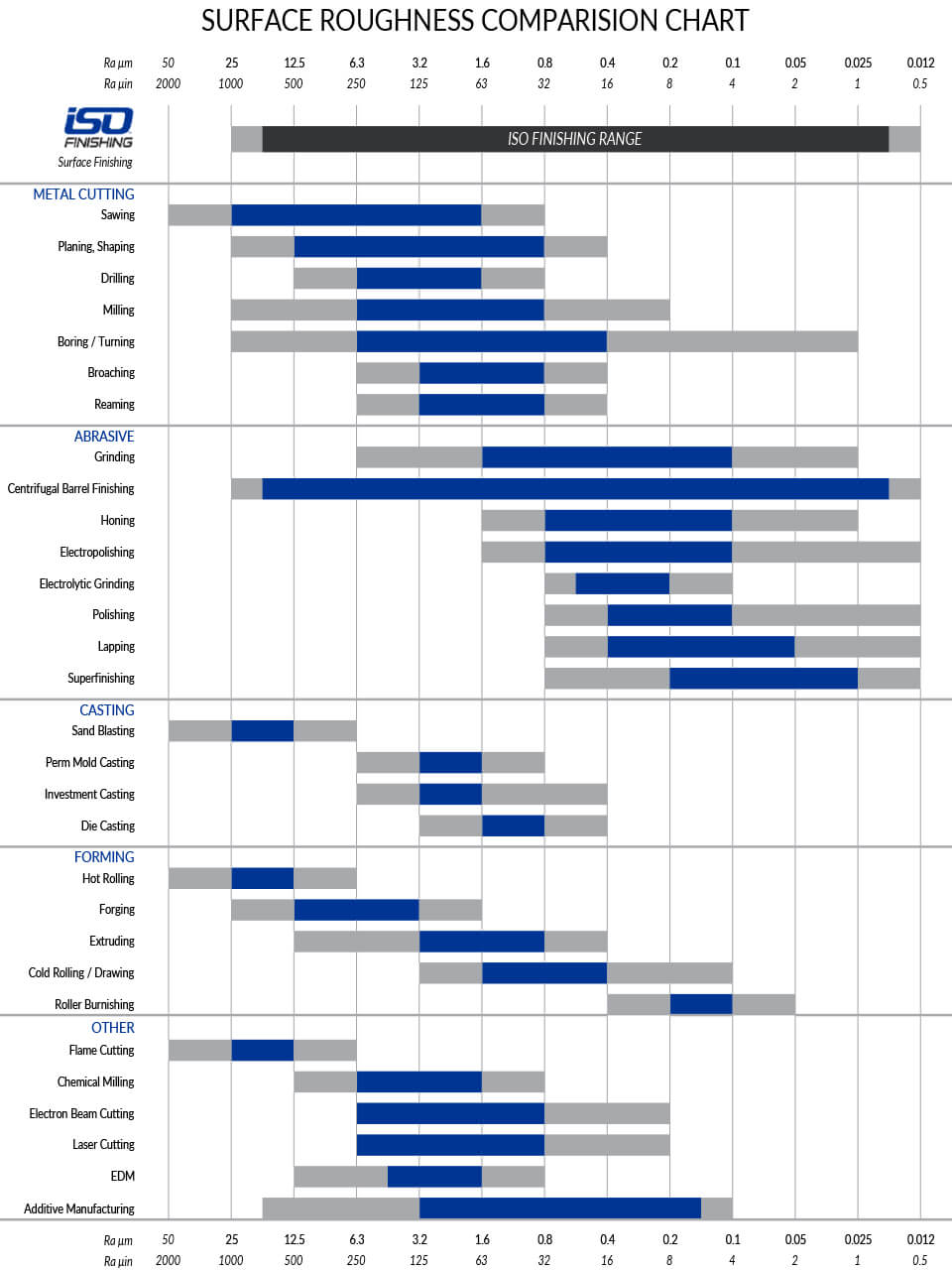

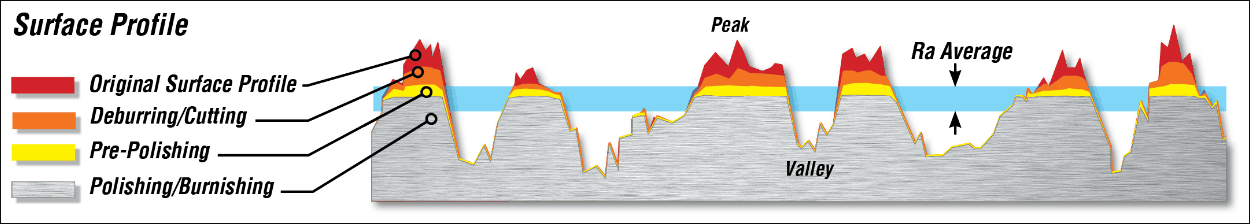

Every production process creates irregularities in the topographical features of a product’s surface. Seen as flaws, peaks and valleys in differing heights and spacing, these deviations together comprise surface texture. Prior to assembly or use, surface texture must be refined to enhance performance, appearance, corrosion resistance, lessen friction and part fatigue.

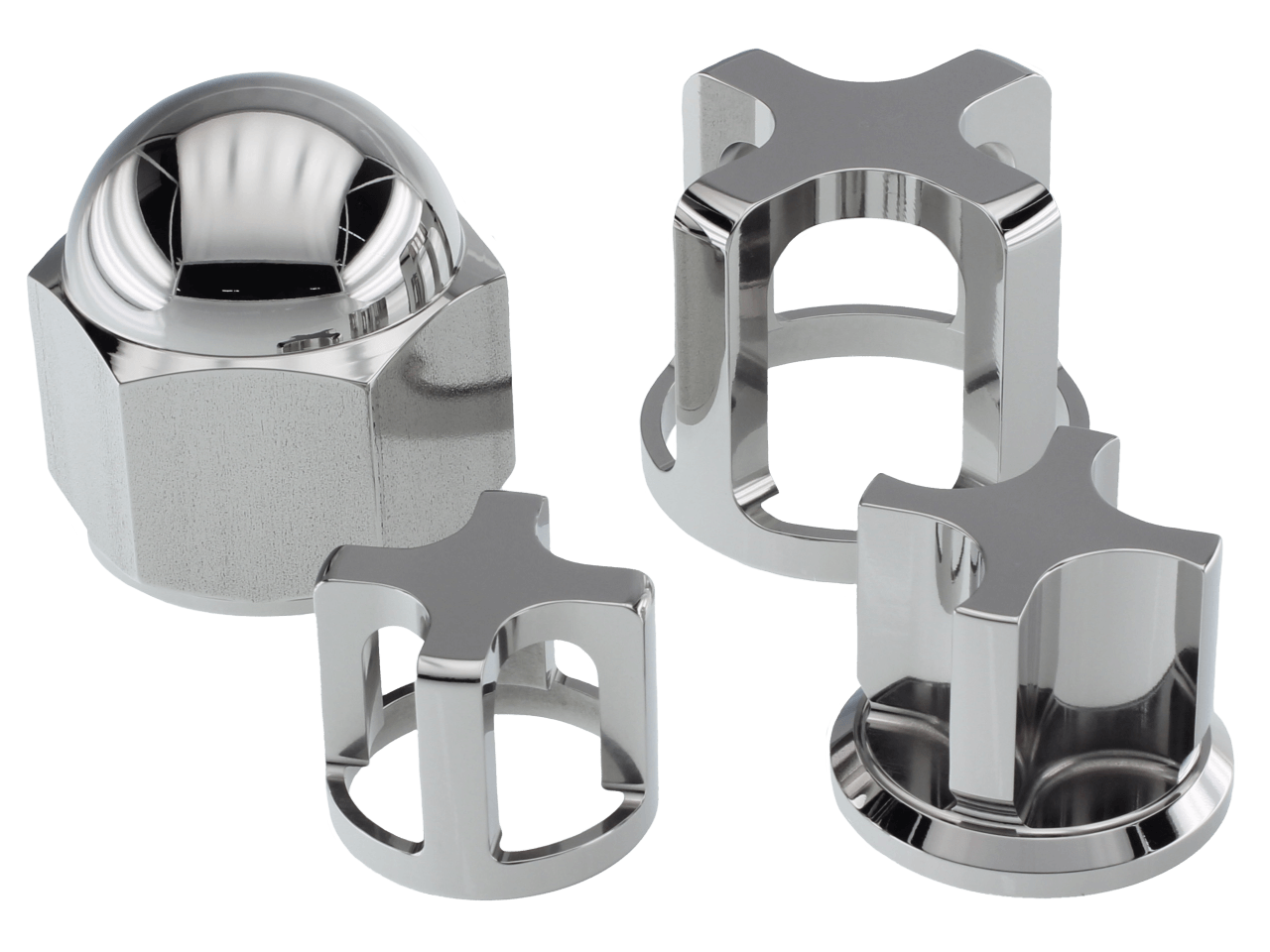

By definition, isotropic is defined as having uniform physical properties in all directions. In mass finishing, an isotropic finish refers to the component’s surface no longer having discernable peaks, valleys, grinding marks or burrs which may have been created during production. Following isotropic surface finishing, a microscope is often needed to see any minute imperfections that may remain.

At ISO Finishing, we put the ISO in isotropic. We are experts in developing customized finishing solutions for products in any material. Documented and repeatable, our isotropic finishing solutions address all attributes of surface texture – including roughness, waviness, and flaws.

The best way to show you first-hand how our finish will become your finish is to process your sample. Let us show you what we can do.

LET’S GET IT FINISHED.