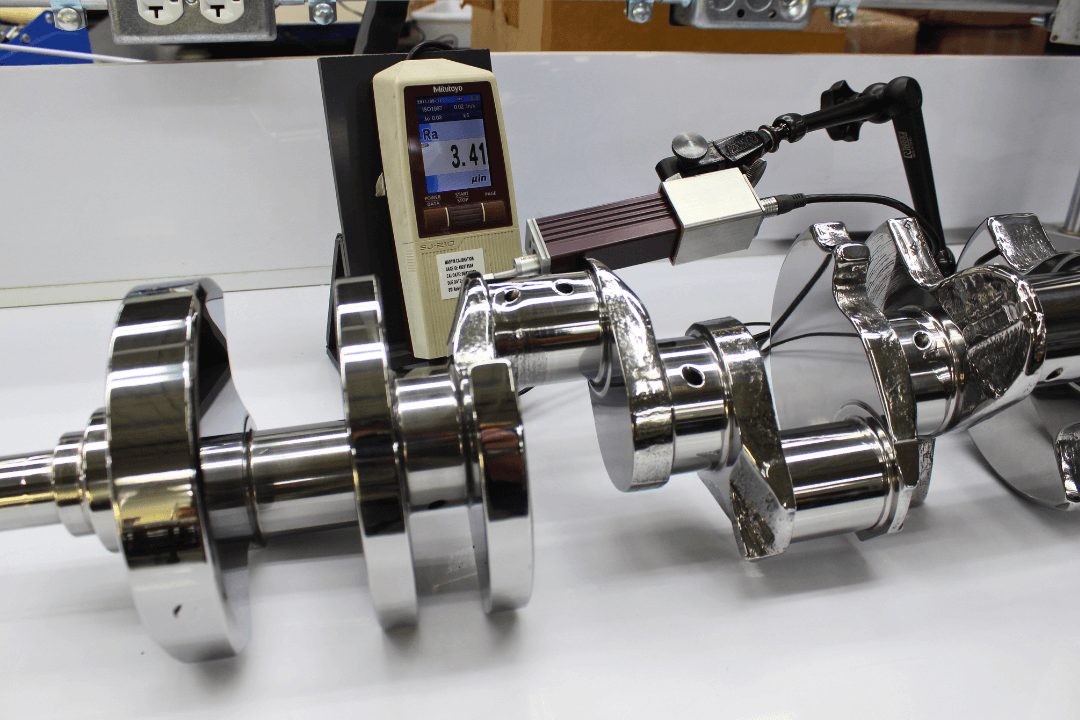

Surface Finishing Process Design

At ISO Finishing, there’s no one-size-fits-all approach to creating surface perfection. We provide tailor-made finishing services for companies across the USA, utilizing the best surface finishing and optical surface profile equipment. Some manufacturers find this in-house, turn-key solution the best way to leverage logistics.

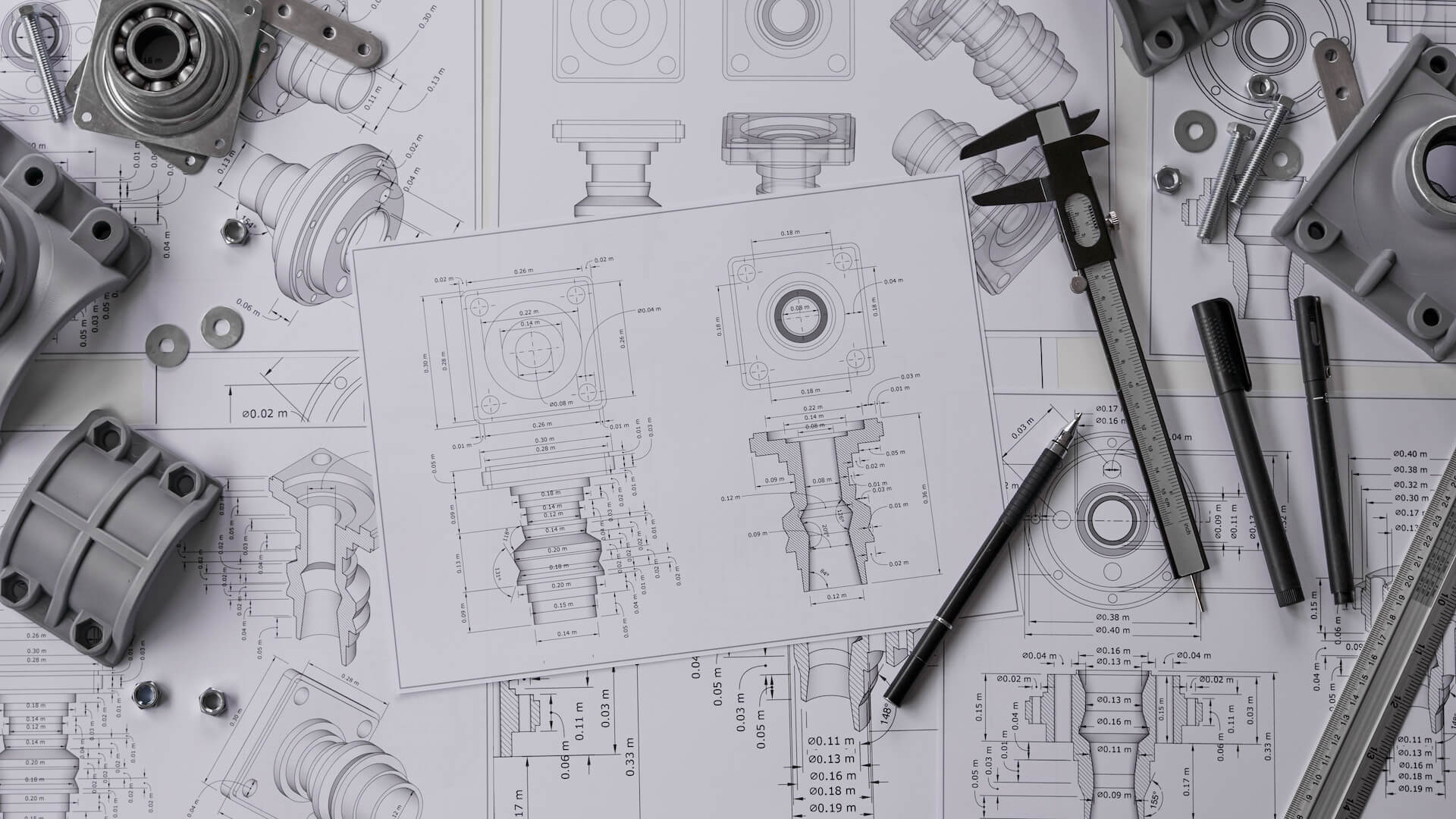

Utilizing our Process Engineering Services, we work with companies to create surface finishing process design solutions with on-going support — including equipment, tumbling media sales, and processing parameters.

Through our innovative finishing solutions and collaboration with you, we formulate a process for each product and use your feedback to adjust the process — not the standard. The result is a customized, documented and repeatable process to ensure each finished product exceeds the most demanding standards.

BENEFITS OF PROCESS ENGINEERING

- Reduce Time to Market

- Process Training

- Decrease in R&D (NRE)

- On-going Support & Troubleshooting

- Equipment Set-up

- Validated Processes Allow ISO Finishing to Act as Overflow Processing Provider When Needed

Fast Facts

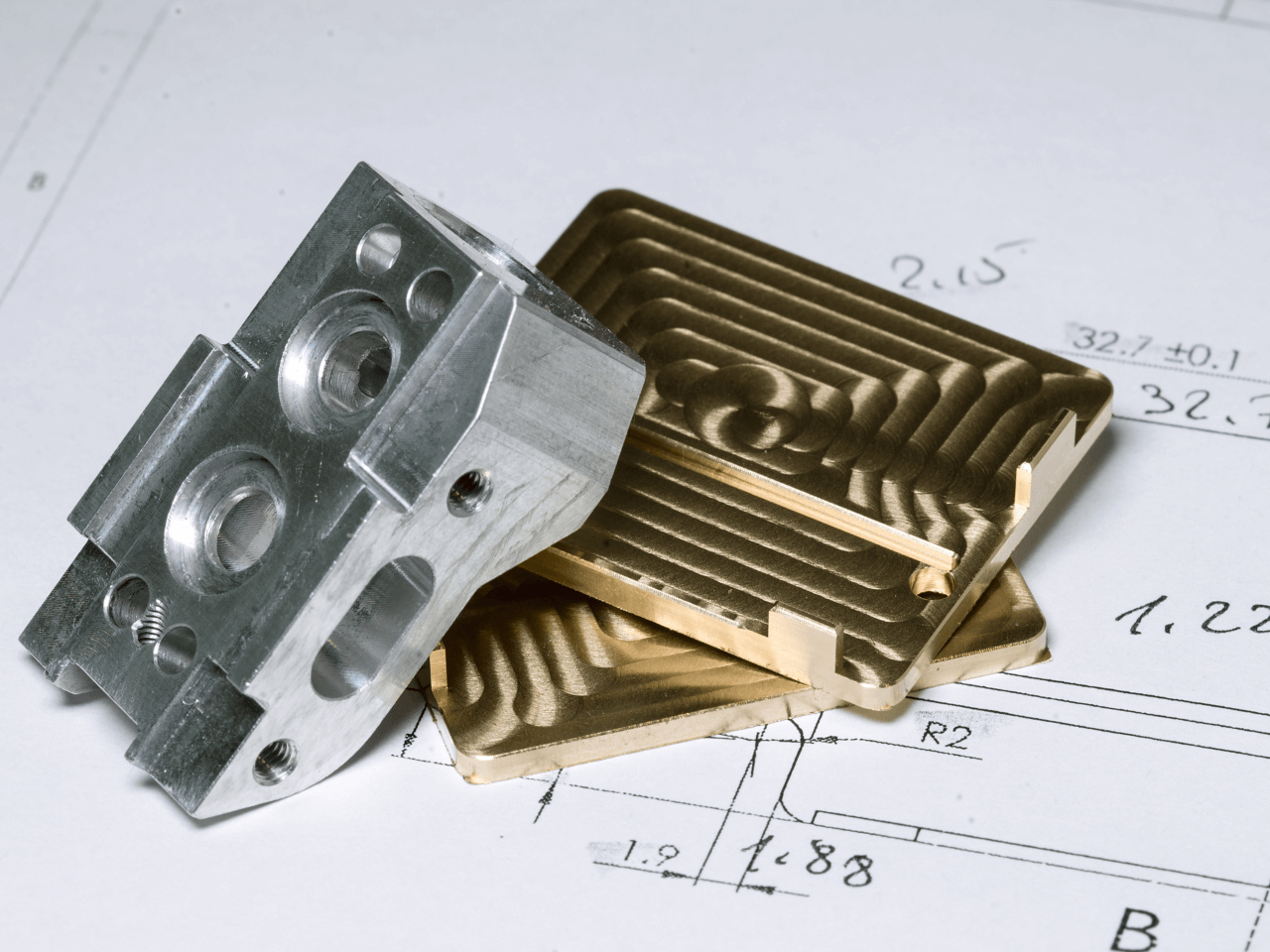

- A single process can take months of research and development.

- Proper finishing compounds and ratios can reduce unit expense.

- Surface finishing can be up to 30% of a component’s overall cost.