Metal parts are used for a variety of applications in every industry and often require some level of surface improvement prior to use or assembly. Surface finishing, also referred to as polishing, is an essential step in preparing parts for coating as it refines surface roughness, eliminates imperfections, minimizes corrosion, and improves coating adhesion.

Surface roughness is primarily determined by two factors – material type, such as stainless steel, titanium or plastic, and the process used for manufacturing, such as machining, injection molding and casting. Secondary operations such as heat treating, welding and blasting also have an effect on surface roughness and factor into the surface finishing process.

As noted above, preparing metal parts for surface finishing can vary greatly. The type of surface coating being applied and the final intended use of the product often dictates the level of surface finishing required. Regardless of the coating type, metal surfaces must be free of contaminants encountered during manufacturing and shipping – such as grease, oil and corrosion.

While surface finishing is typically used to reduce overall surface roughness, deburr and descale parts, there are situations where an ultra-smooth finish is not ideal. Variations in surface finishing techniques can create surface textures such as stippled or matte for better adhesion of certain coatings.

Multiple surface finishing processes may be used to prepare parts for coating application, such as:

The removal of heat treat or casting scale is the first step in preparing surfaces for coating. With the scale removed, complete visual inspection of the part is possible to uncover any manufacturing defects or voids.

For example, descaling can expose imperfections on cast magnesium automotive parts which were not previously visible. Defective parts can be reworked or scrapped – saving the manufacturer time and money.

Next, the interior and exterior of the parts undergo deburring using either centrifugal barrel finishing (CBF) or vibratory processing. As pre-requisite for surface coating, deburring removes any build-up of machining burrs and other surface flaws. Deburring also improves product quality, increases the lifespan of a part and enhances aesthetic appeal.

Following any descaling and deburring processes, parts move into the polishing phase. Polishing is essential as the surface is refined further using incrementally less coarse media resulting in a uniform, clean surface ready for coating application.

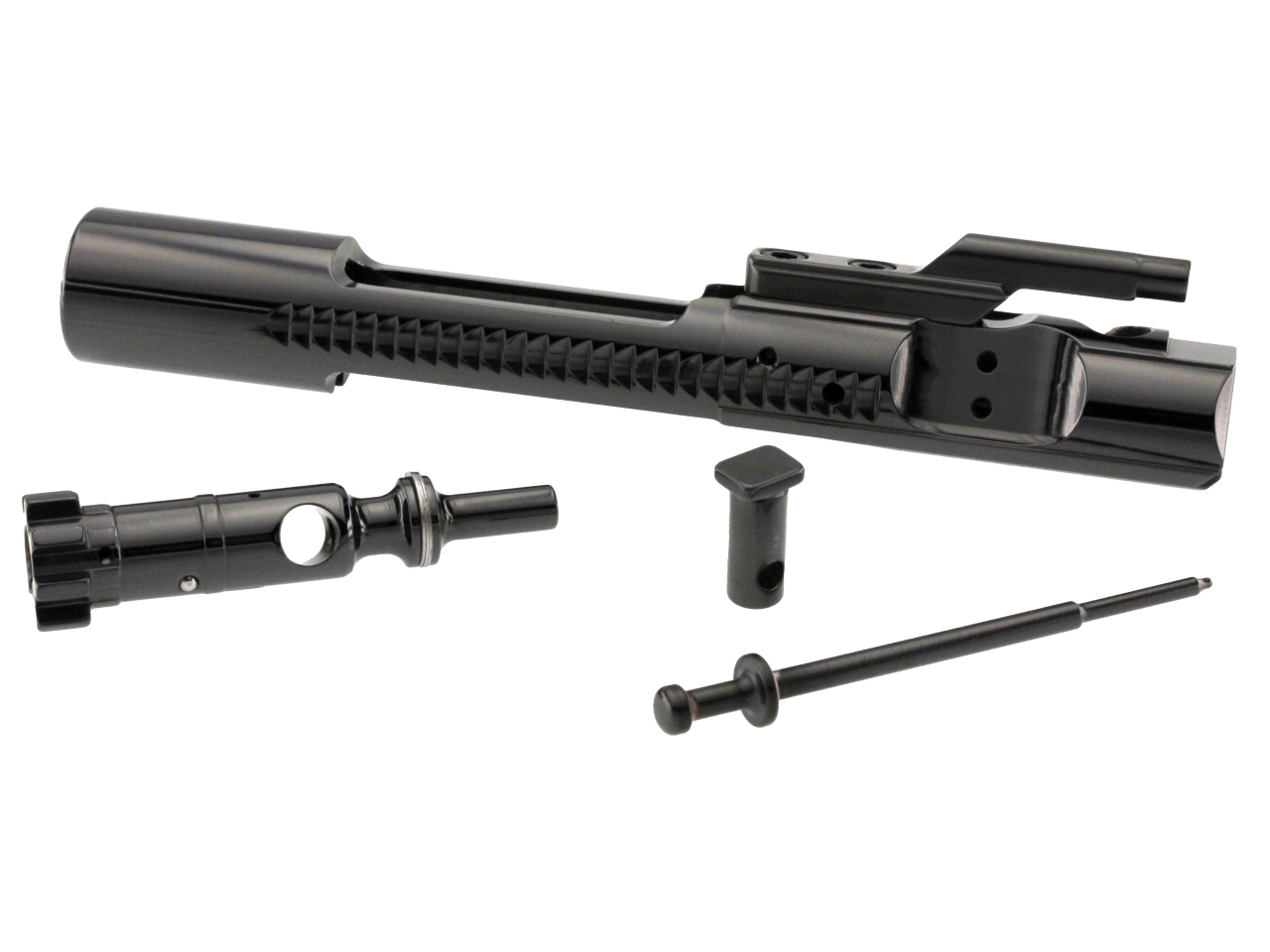

When the surface is properly prepared and the required surface roughness is achieved, parts are ready for coating application. Common types of surface coatings include powder coating, plating, titanium nitriding and thin-film or DLC coating. Each coating type serves a different function and a parts’ end use is indictive of the type of coating required. For example, a firearm may need powder coating for corrosion resistance, or an orthopedic implant may need a biocompatible thin-film to lessen friction and part fatigue.

With more than 35 years in metallurgy, tribology and manufacturing, the experts at ISO Finishing will create a surface finish process to prepare your parts for coating that is documented and repeatable. We’ll use your feedback to adjust the process – not the standard.

The best way to show you how our finish will be your finish is to process your sample. Let us show you what we can do.

LET’S GET IT FINISHED.