Surface Finishing for Precision Parts

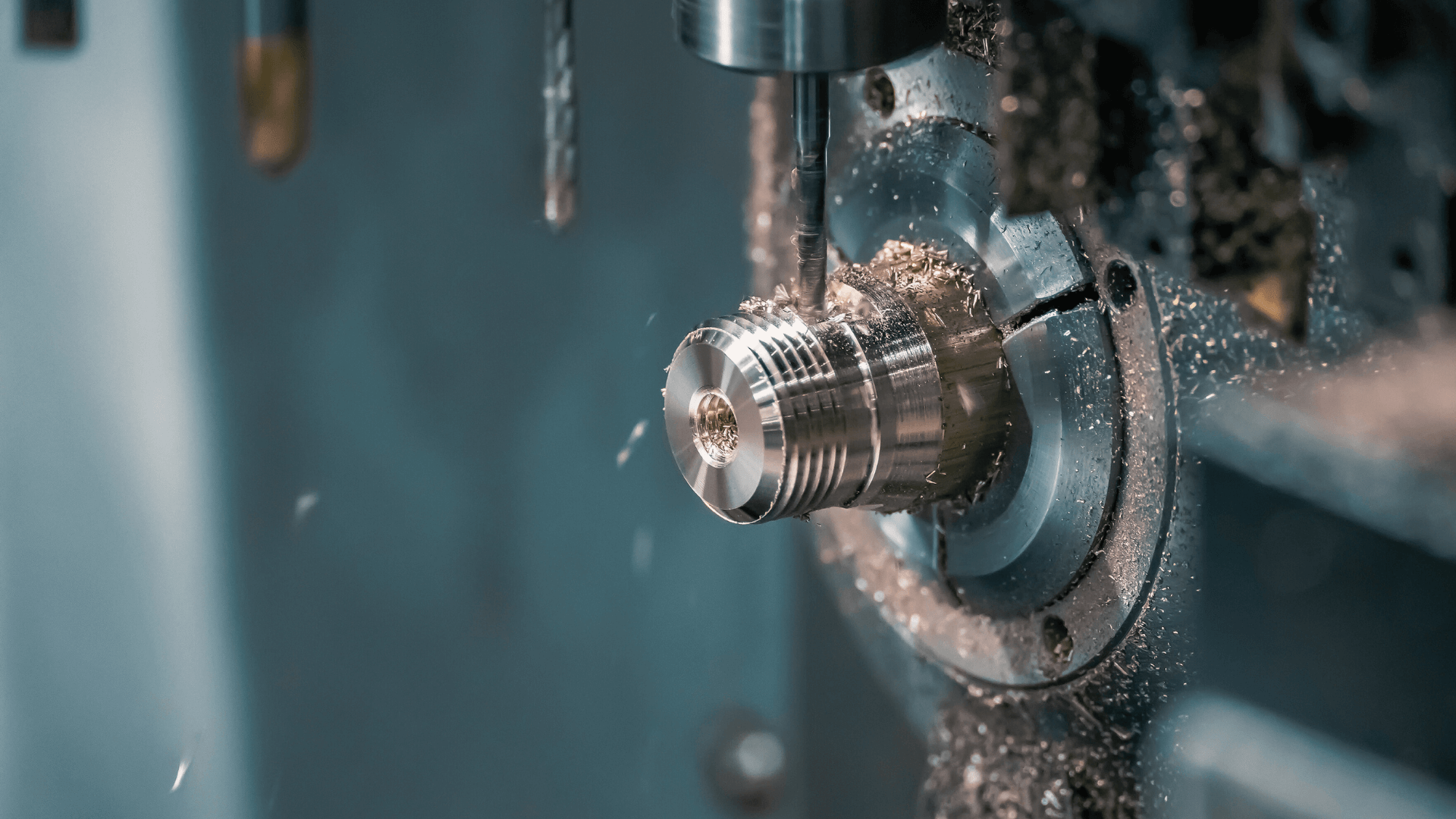

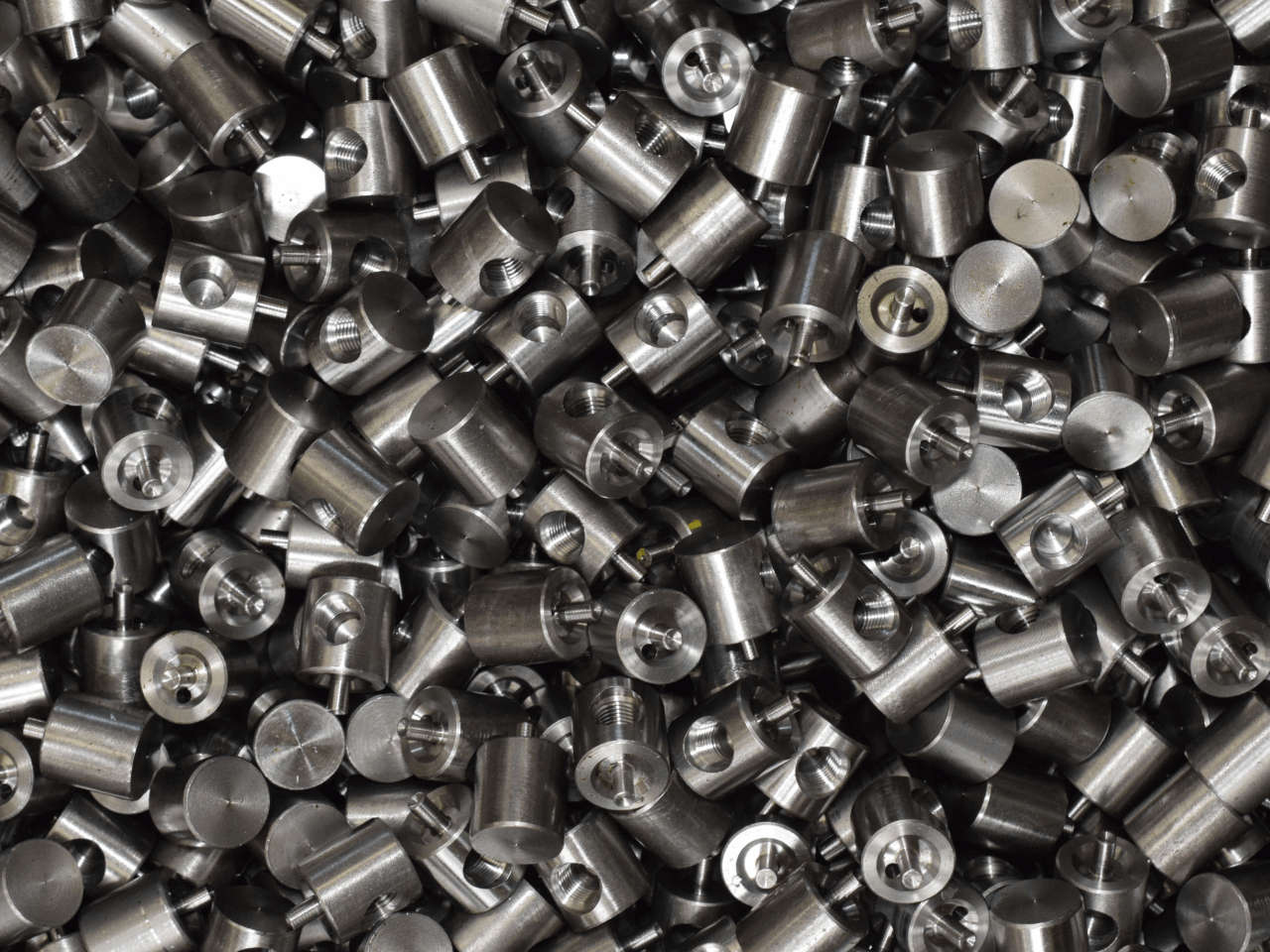

The most critical industries often rely on small, symmetrical components. Not just another rotating spindle, a CNC Swiss precision machining lathe can create parts as small as 3mm3 with complex geometries and extremely tight tolerances commonly used in medical devices, aerospace and electronics.

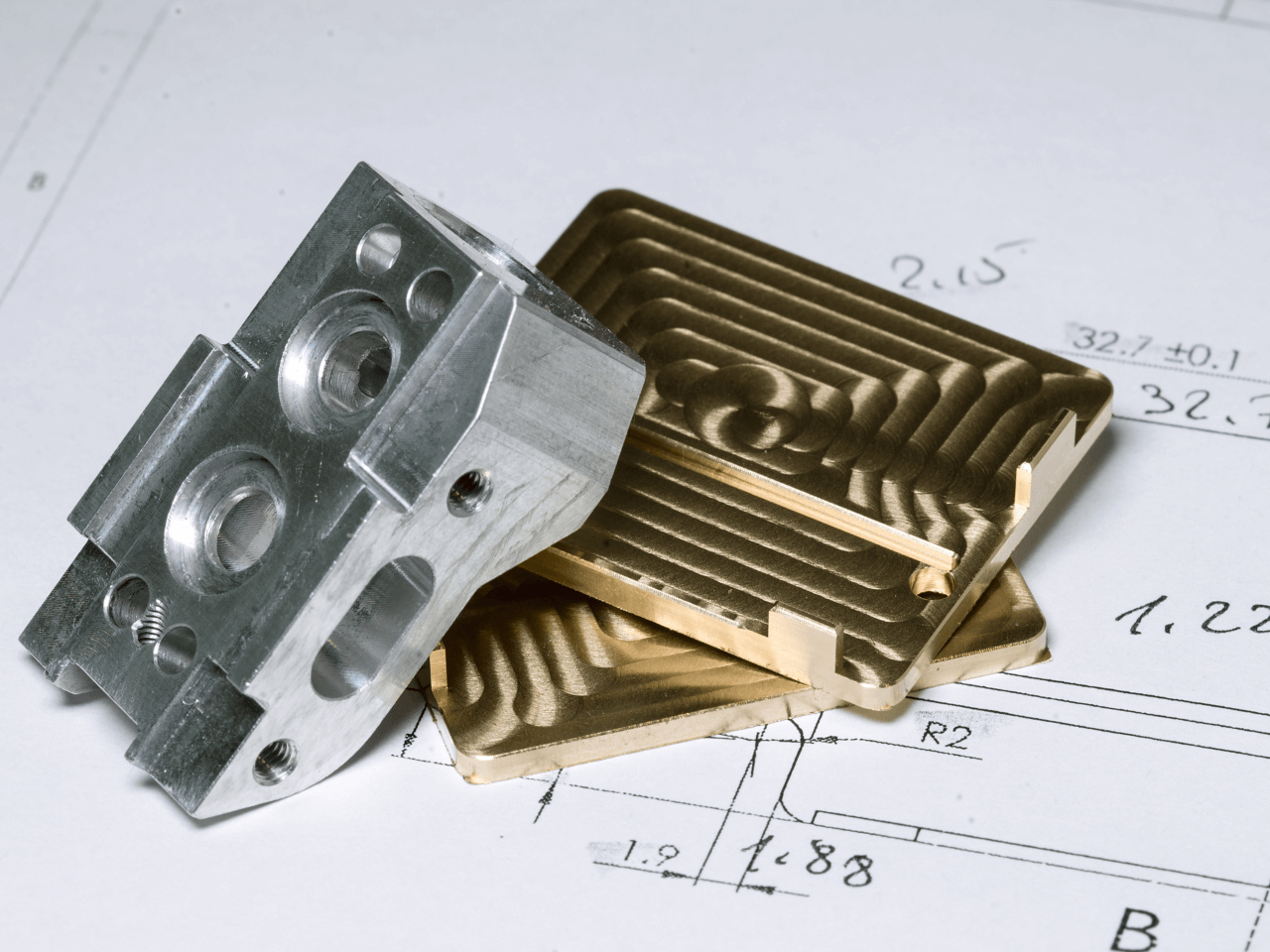

CNC Swiss lathe machining services produce parts with less chatter and deflection. However, these parts may still require some level of deburring, polishing and micro-surface improvement prior to ancillary processes or use.

ISO 9001:2015 certified, ISO Finishing’s team are experts in creating CNC polishing and finishing solutions. These uniform surface finishes are customized, documented and repeatable, preserving all initial geometries and meeting even the tightest specifications.

Resources

BEFORE & AFTER

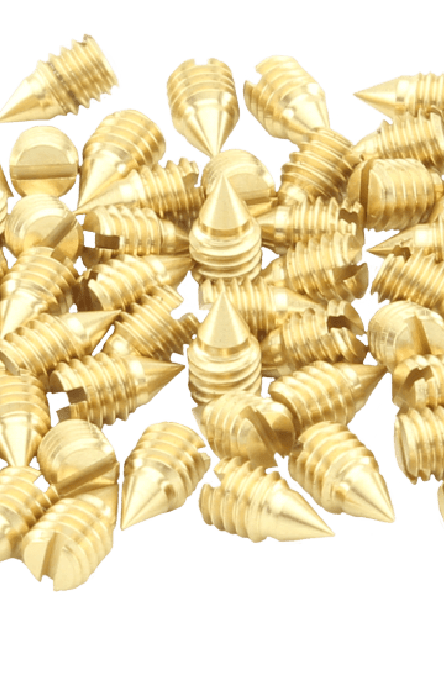

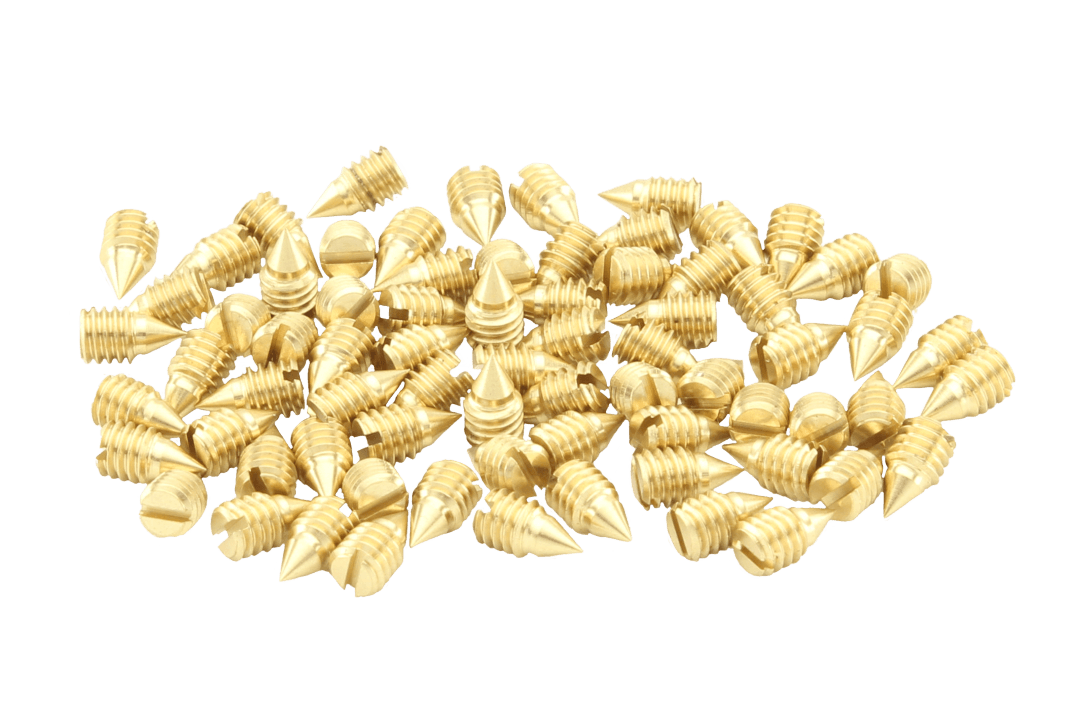

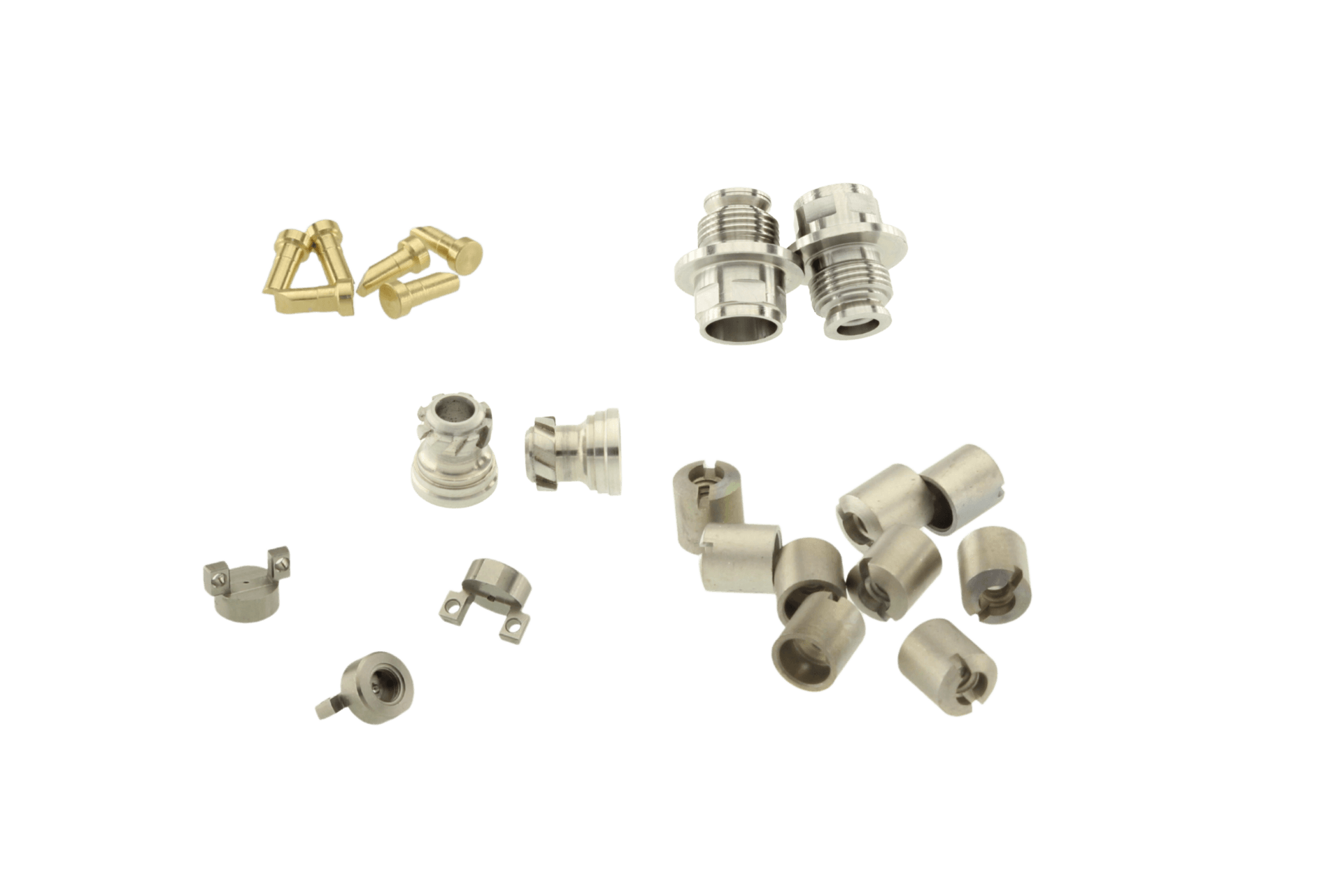

BRASS ELECTRICAL CONNECTOR

CNC Swiss Machining I Deburring, Polishing

OEMs are an integral part of the supply chain by providing components and assemblies to many of the world’s largest and most respected brands. Many of these OEMs focus on the processes with which they are best suited and most efficient. Many downstream services are provided by specialists like ISO Finishing to fill in the gaps to keep their production rolling. The sample here is an electrical connector which needed to be polished for the application of a corrosion inhibitor.