Expert Finishing Services for Any Parts

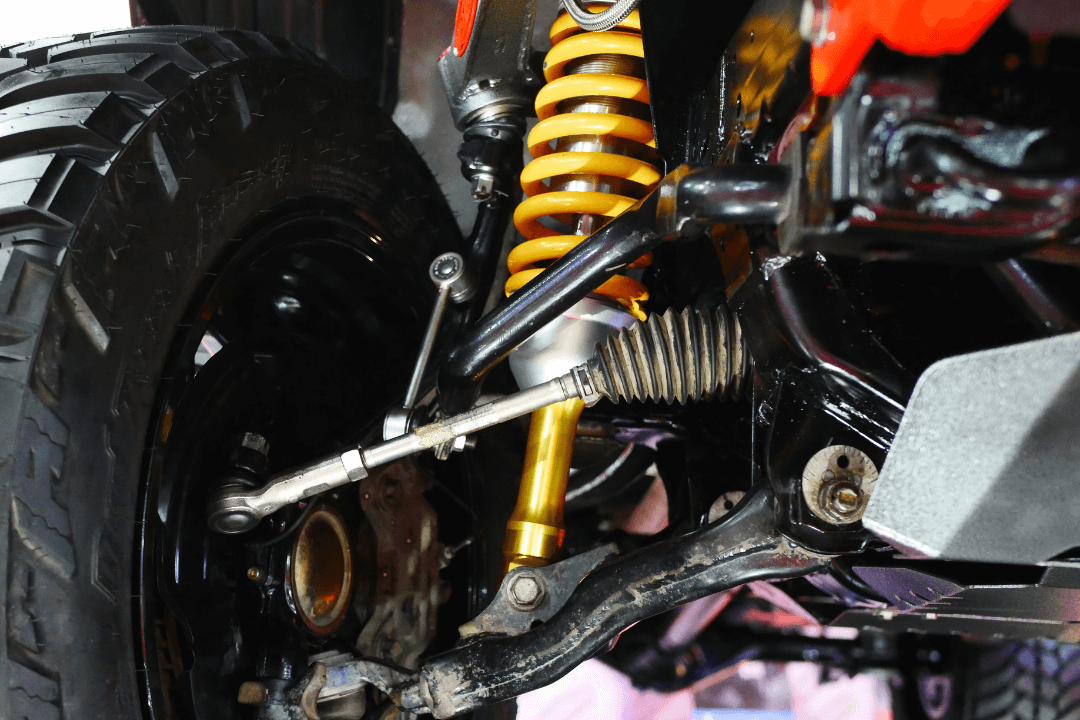

Instant worldwide connection has changed the speed, diversity and logistics of modern manufacturing. Companies now rely on original equipment manufacturers (OEMs) to produce components, parts and assemblies to their exact specifications to meet the demands of an ever-changing supply chain.

Larger OEMs may have the capacity and expertise for production from start to finish, others look to outside resources to fill gaps — such as heat treating, metal fabrication, finishing and plating.

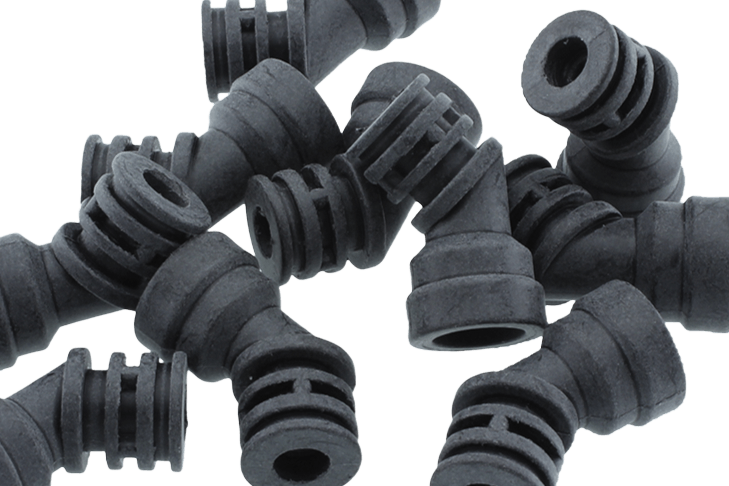

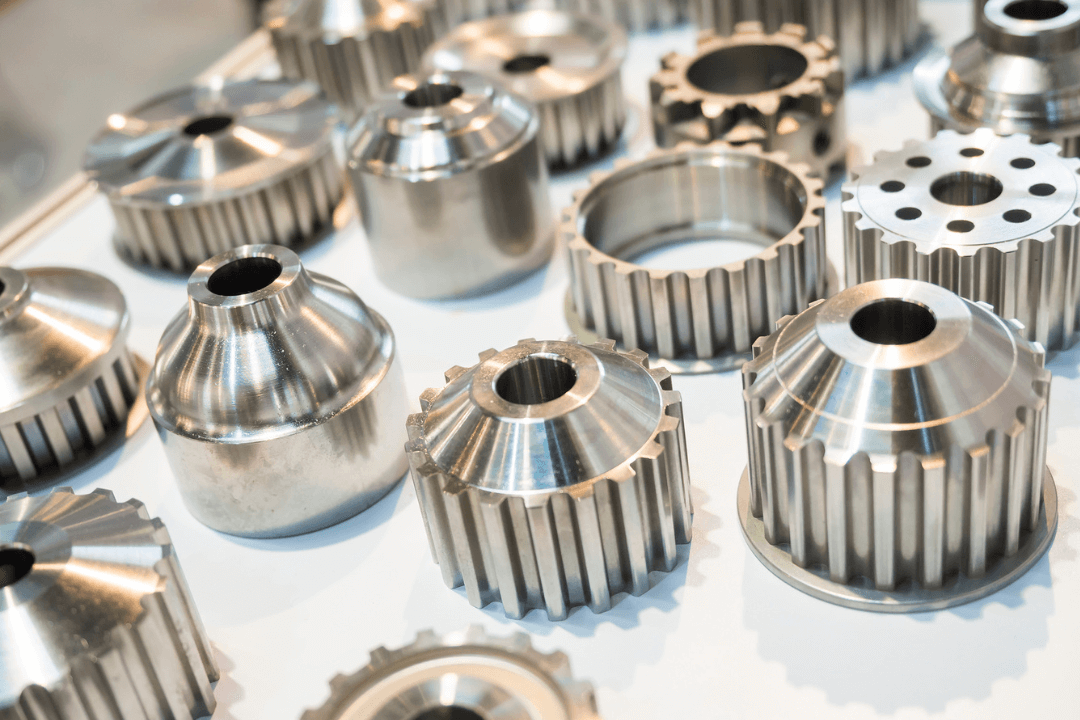

OEMs trust ISO Finishing’s expertise for wide-ranging surface solutions, from simple burr and flashing removal, to multi-step polishing and micro-surface improvement. We are experienced in tailoring OEM metal finishing processes for injection molded, 3D printed, stamped, machined, cast and welded components to meet even the most rigorous requirements.

Resources

BEFORE & AFTER

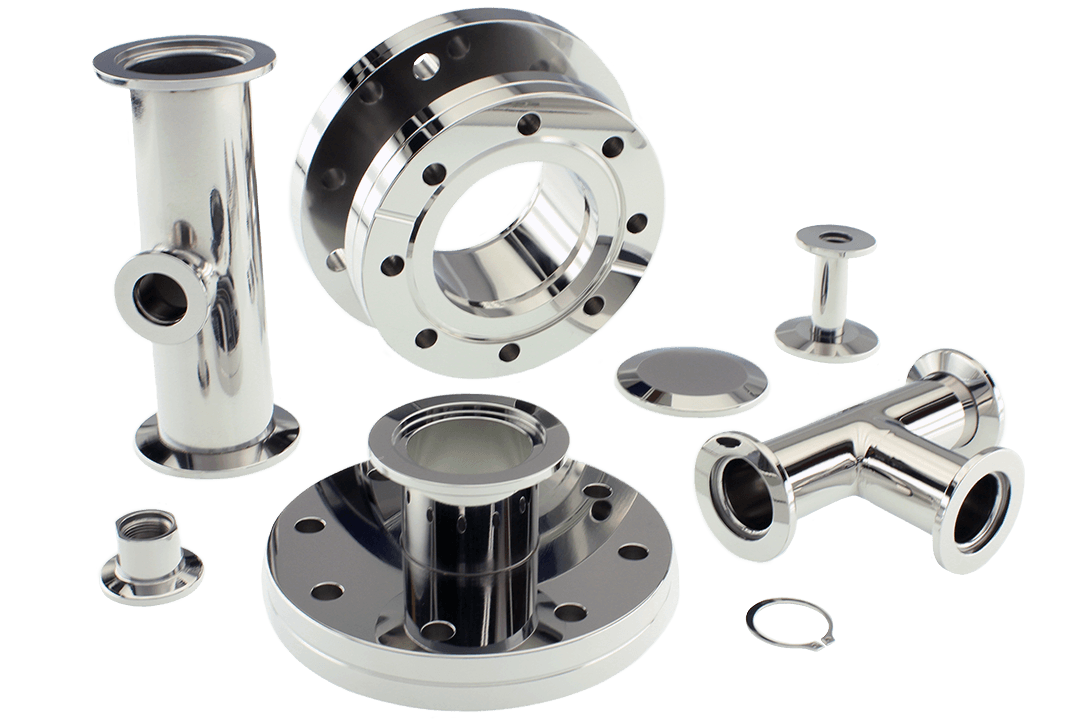

CAST STAINLESS STEEL PUMP HOUSING

OEM I Descaling, Polishing

One of the key benefits of casting is to be able to make a part with different sizes, shapes, cavities and thicknesses all at once from a single source. It eliminates the need to machine the part from a solid block of material, greatly reducing the overall cost of production. It can also eliminate the need for welding or brazing of tubes or flanges as well as the post process cleaning of these areas to eliminate any contamination or oxidation. In the sample shown here, ISO Finishing used several aggressive cutting steps to remove the scale and get to the point where we could start refining the surface. Additional pre-polish cycles were used followed by a final dry polish to complete the process.