Surface Finishing Processes Delivering Exceptional Results

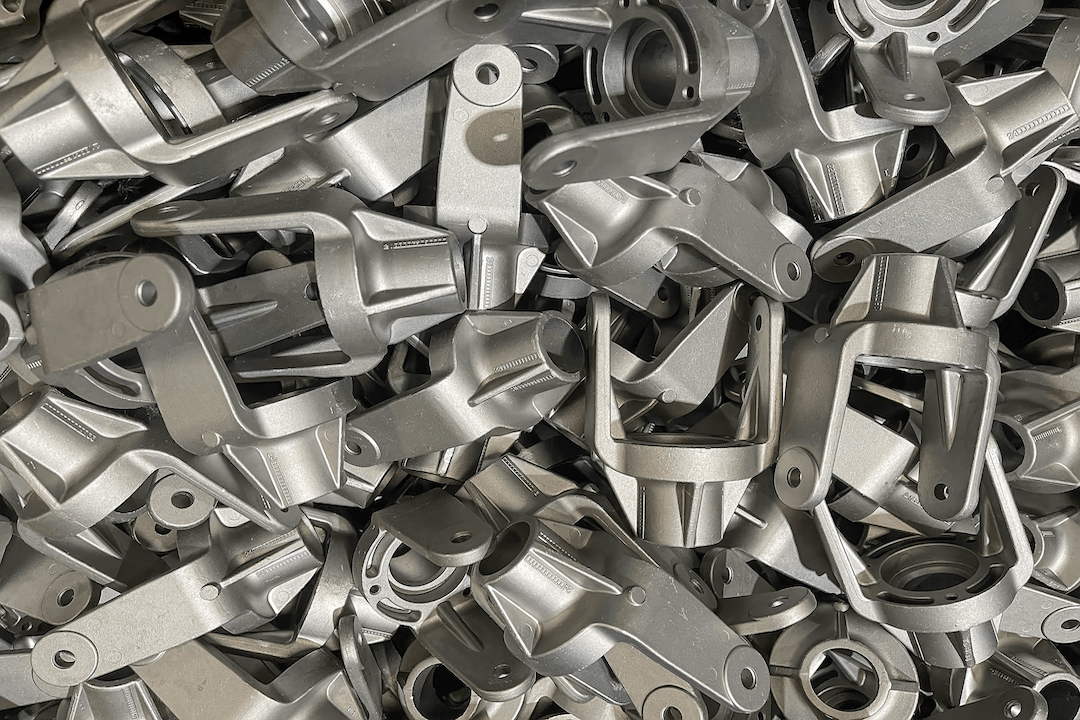

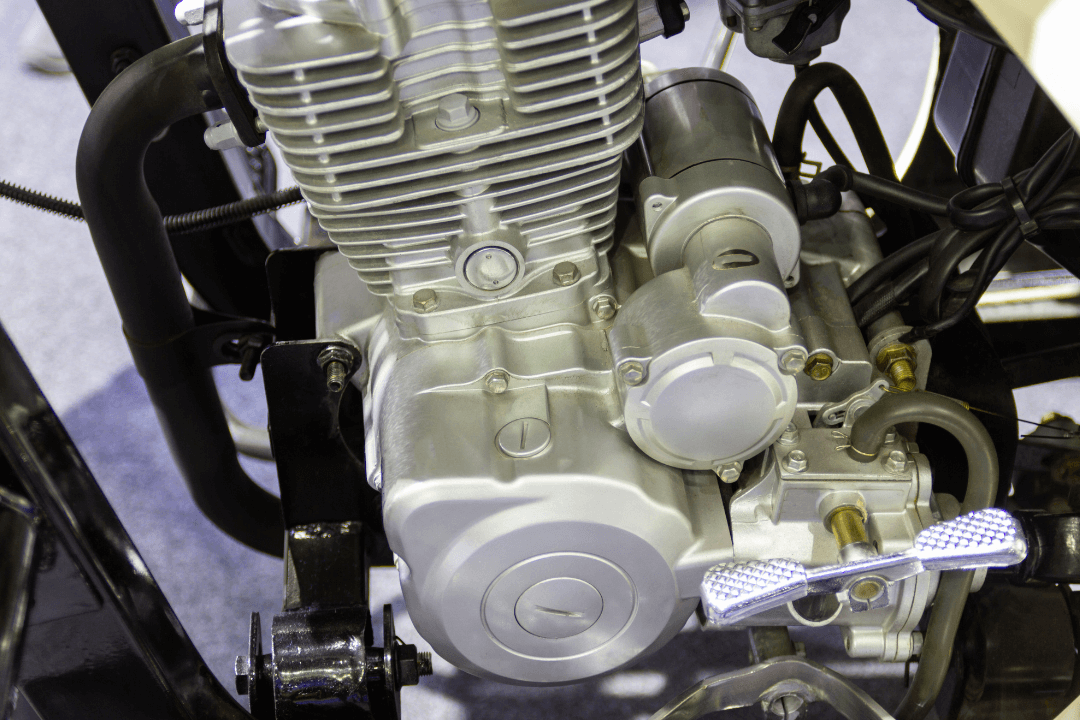

Known for their cost effectiveness and high-volume capabilities, manufacturers in nearly every industry rely on injection molded, die-cast and forged parts. While versatile and customizable in virtually every material, the byproduct of production is often residual flashing and gates, requiring removal prior to part use.

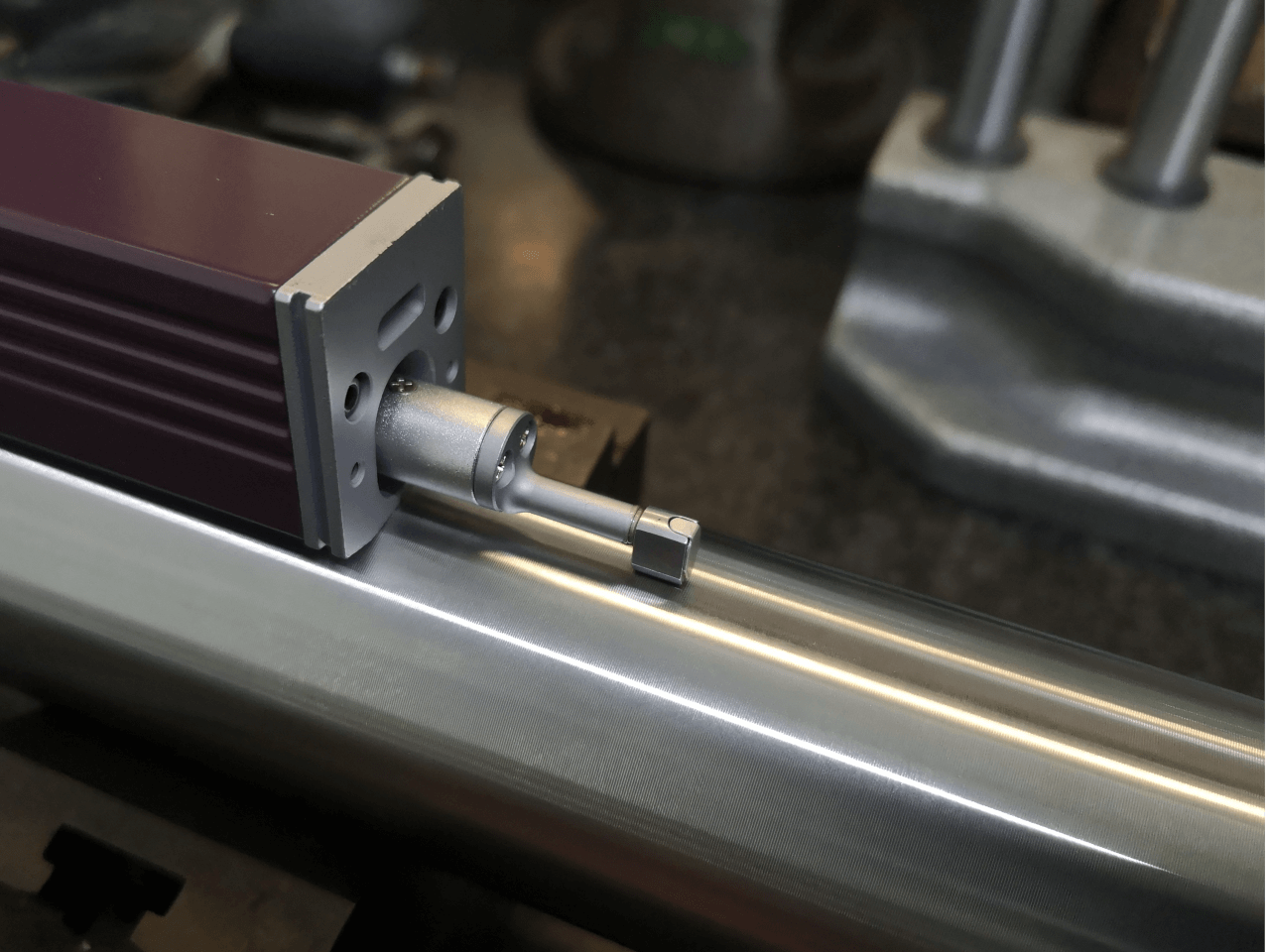

Regardless of the surface finish your part requires, ISO Finishing has experience in simple burr and parting line removal to multi-step cutting and polishing of die-cast and injection molded products. Our documented and repeatable processes are suitable for parts in any material and will meet even the strictest requirements.

Resources

BEFORE & AFTER

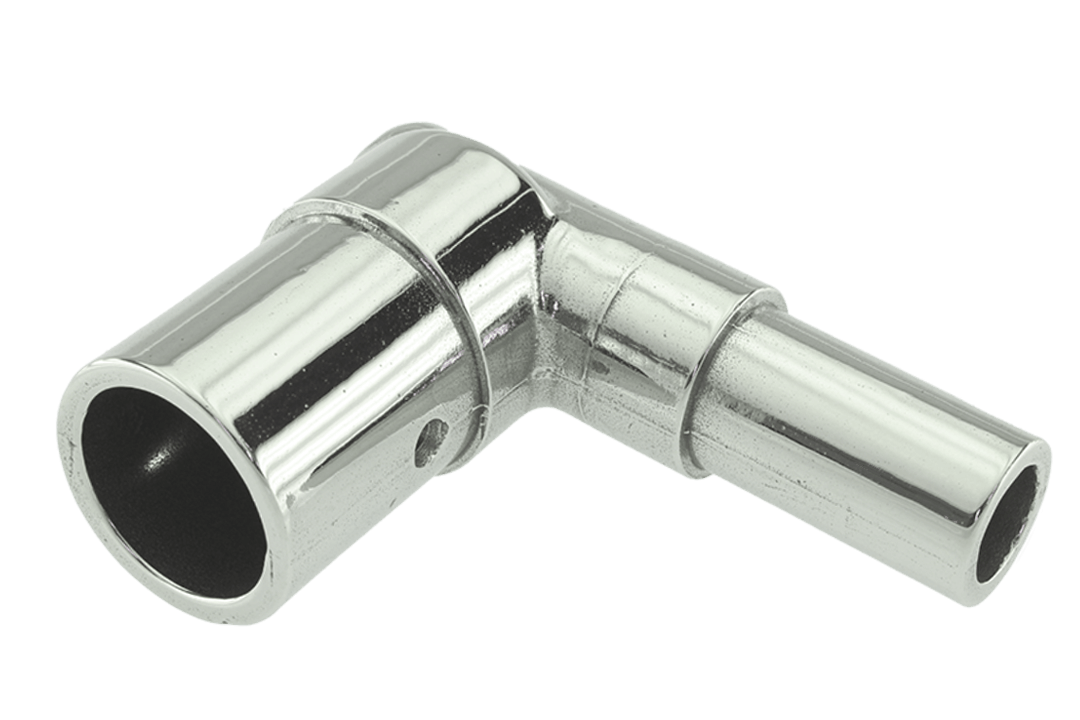

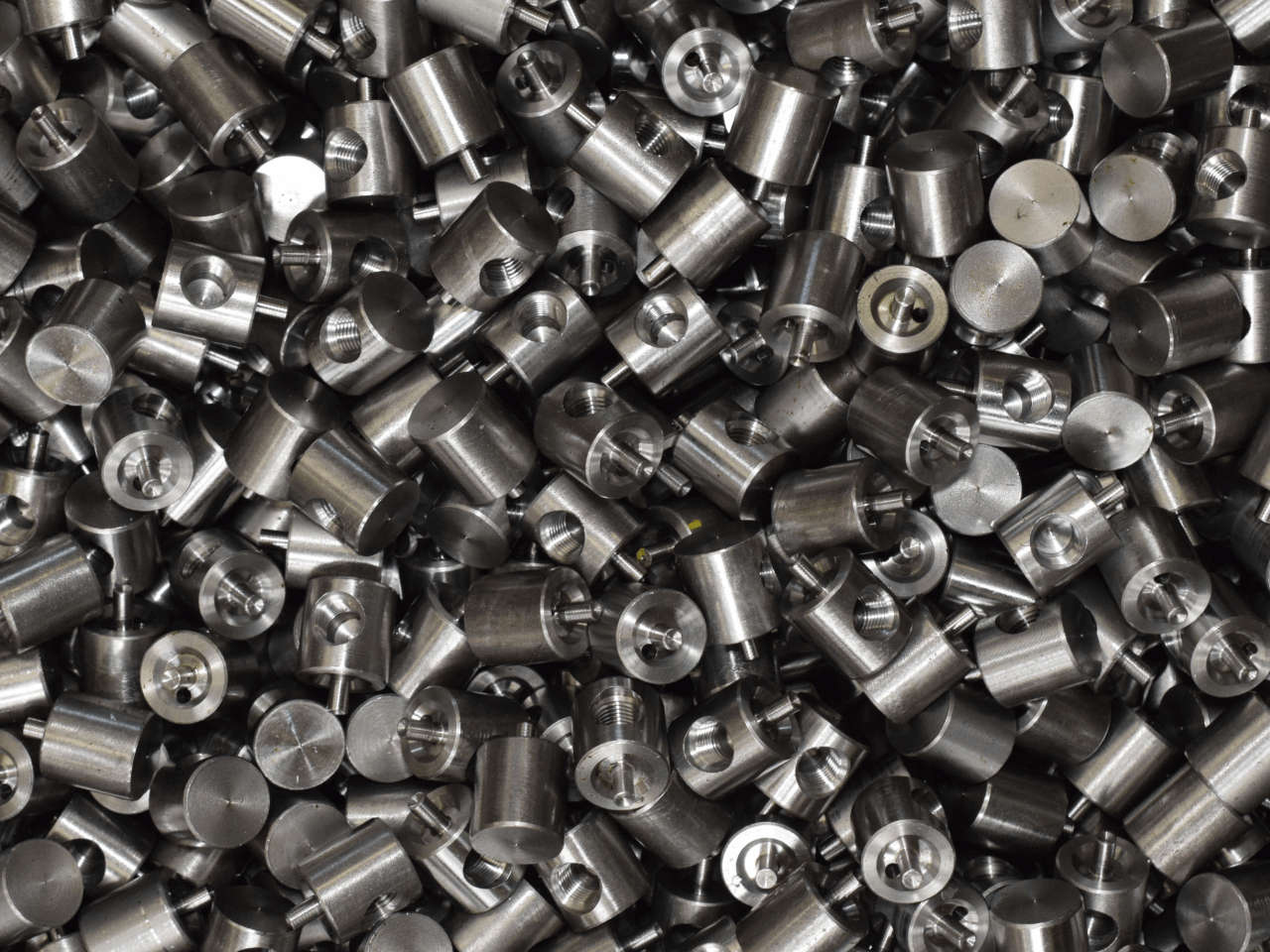

CAST STAINLESS ARMATURE ASSEMBLY COMPONENT

Molding & Casting I Descaling, Polishing

With the advances in materials and improvements in precision casting, many components can be produced in a net or near net form. By reducing or eliminating the need for additional machining or secondary processes parts can be much less expensive than those produced by other traditional machining methods. In the marine connection showcased here, ISO Finishing performed a multi-step cut and polish to remove undesired casting imperfections and improve the aesthetics of the component.