Customized Solutions for Mission Critical Components

Few industries require greater innovation, strategy and capability than our nation’s military. Some of the most life-changing civilian technological advances have been a byproduct of our government’s security, defense and communications investments.

From armaments, aircrafts and warships to drones, electronics and surveillance equipment, ISO Finishing has provided vital polishing, deburring and other surface finishing services to manufacturers who supply mission-critical parts to multiple government agencies.

More than just a military and defense component polishing and finishing company, ISO Finishing has defined, designed and documented surface finishing processes for a wide array of metals, superalloys and high-tech synthetic materials.

ISO 9001:2015 certified and CAGE code registered, ISO Finishing’s tailor-made and repeatable solutions result in improved part uniformity, performance and safety, while meeting the most rigorous requirements.

Resources

BEFORE & AFTER

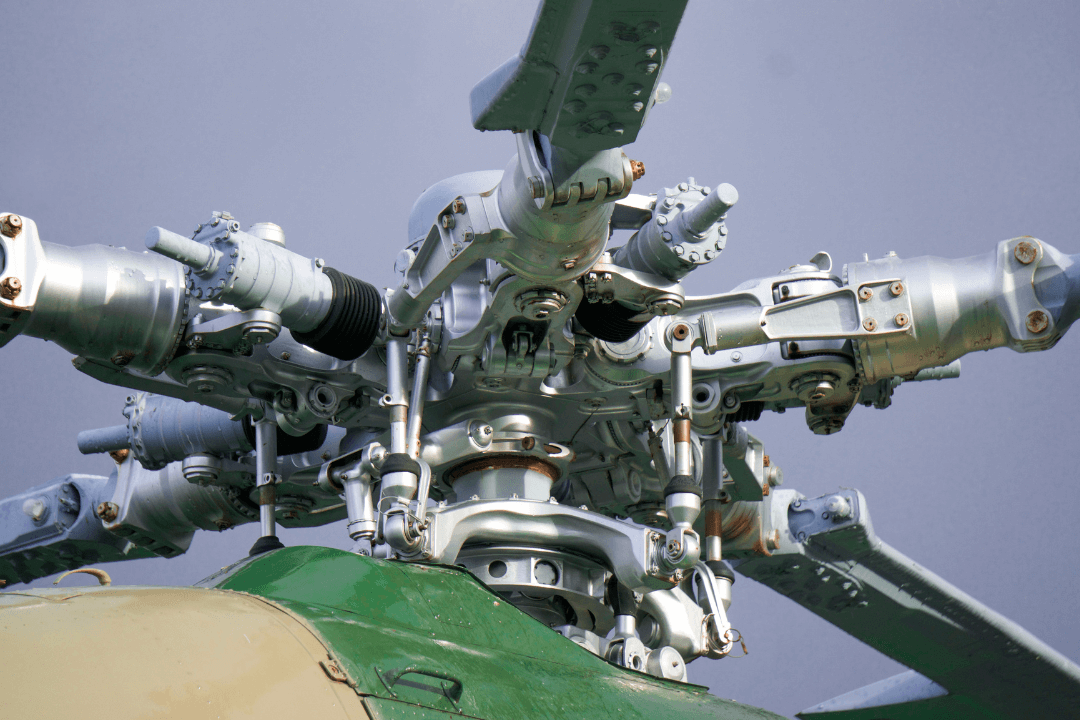

HELICOPTER ROTOR

Military & Defense I Deburring, Polishing, Radiusing

When a helicopter pilot is cruising at several thousand feet at speeds over a hundred miles per hour, they trust the engineering and maintenance of the rotor, blades and hydraulics to work flawlessly. Each of the components has gone through countless hours of validation and testing and have been built with a certain level of redundancy as any part failure can spell disaster for the entire crew. In the titanium rotor above, ISO Finishing removed all burrs and machine marks, blended all adjoining contours and radiused the sharp edges to reduce any opportunity for fatigue failure.