Exact Surface Finishing For Medical Applications

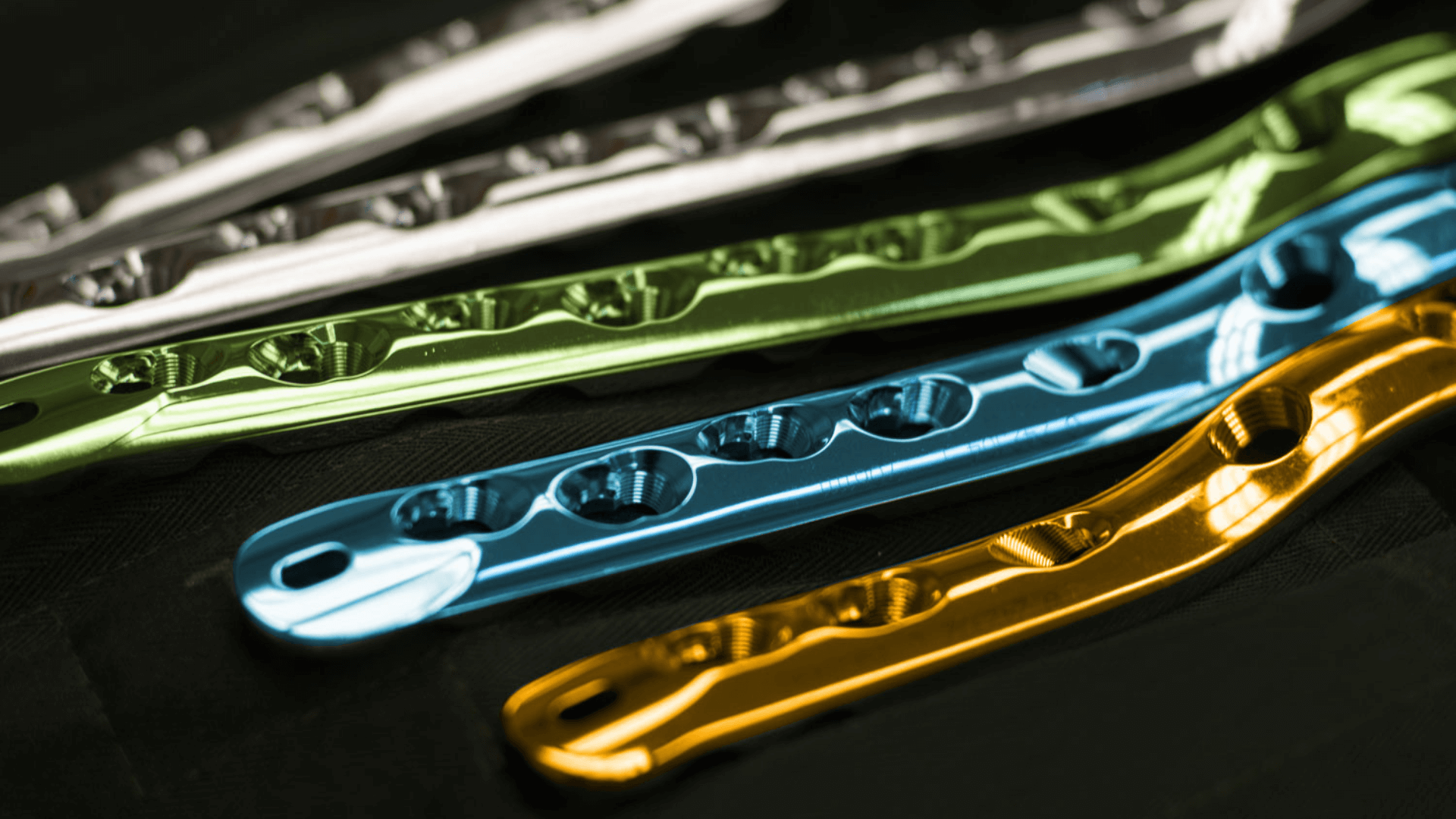

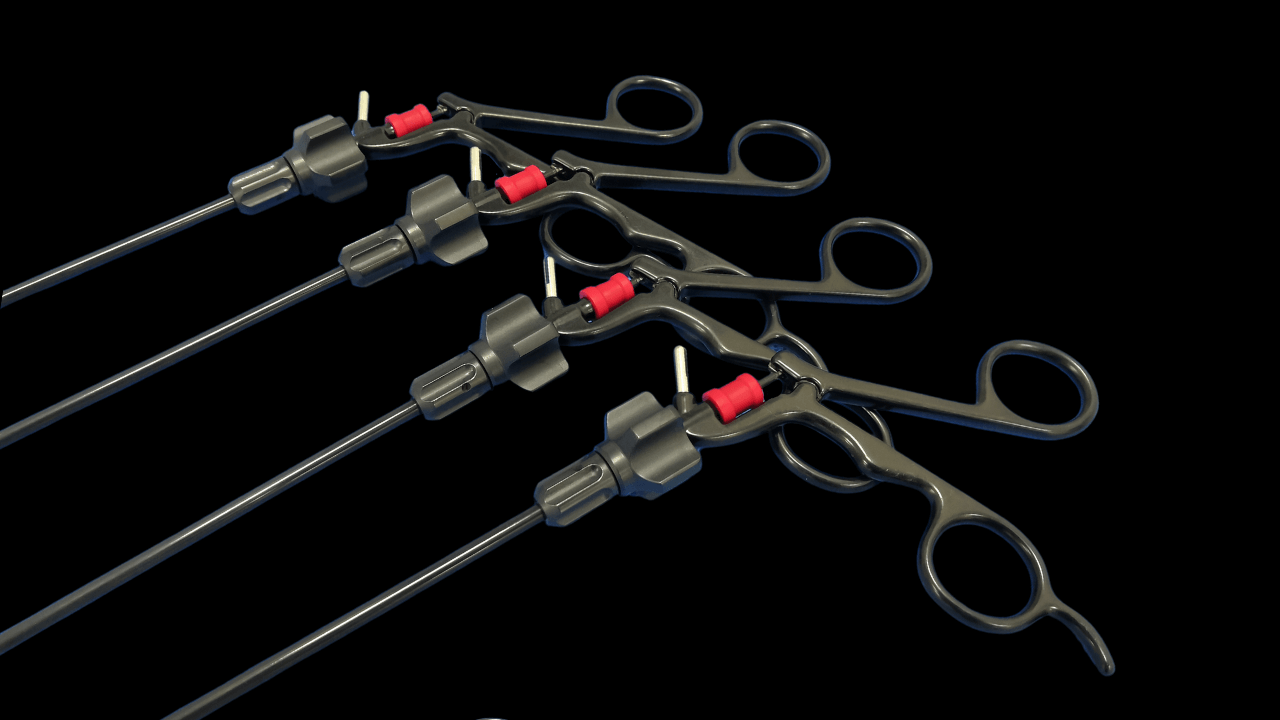

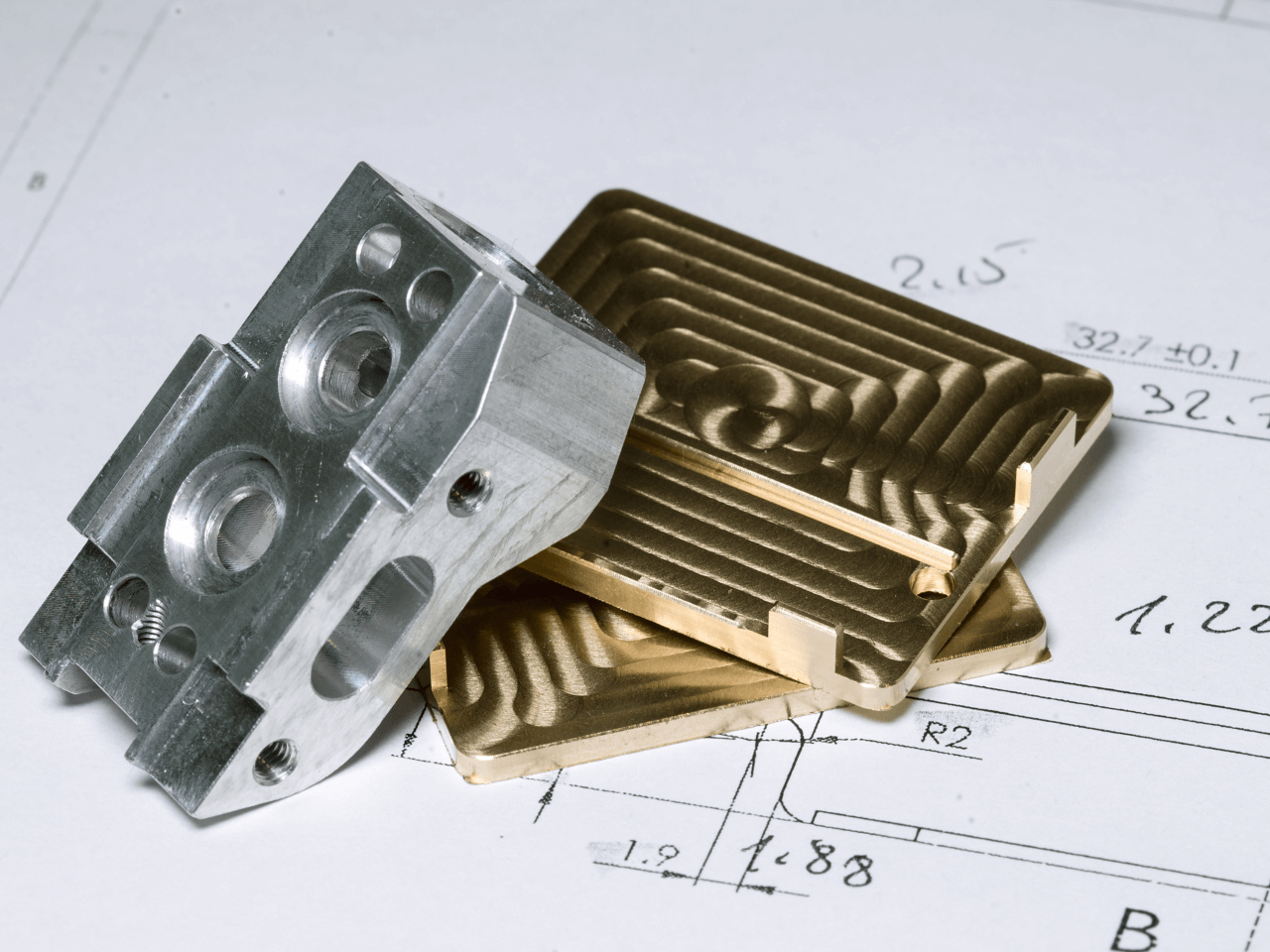

Orthopedic, surgical and vascular components have evolved dramatically over the past few years — both in function and appearance. Medical manufacturers must be agile in producing reliable, cost-effective components in the latest materials and machining techniques.

ISO Finishing has the proven ability to deliver optimal medical device polishing and finishing solutions for components as small as 3mmᵌ. Our medical polishing processes are suitable for finishing devices and products in all materials and metals — including titanium, stainless steel, aluminum, cobalt chrome and nitinol.

ISO 9001:2015 certified, our documented and repeatable surface finishing processes increase component durability and strength, reduce manufacturing cycle times and maximize product yield. The resulting uniform surfaces are ideal for the downstream cleaning and sterilization processes needed to meet even the strictest medical requirements.

Resources

BEFORE & AFTER

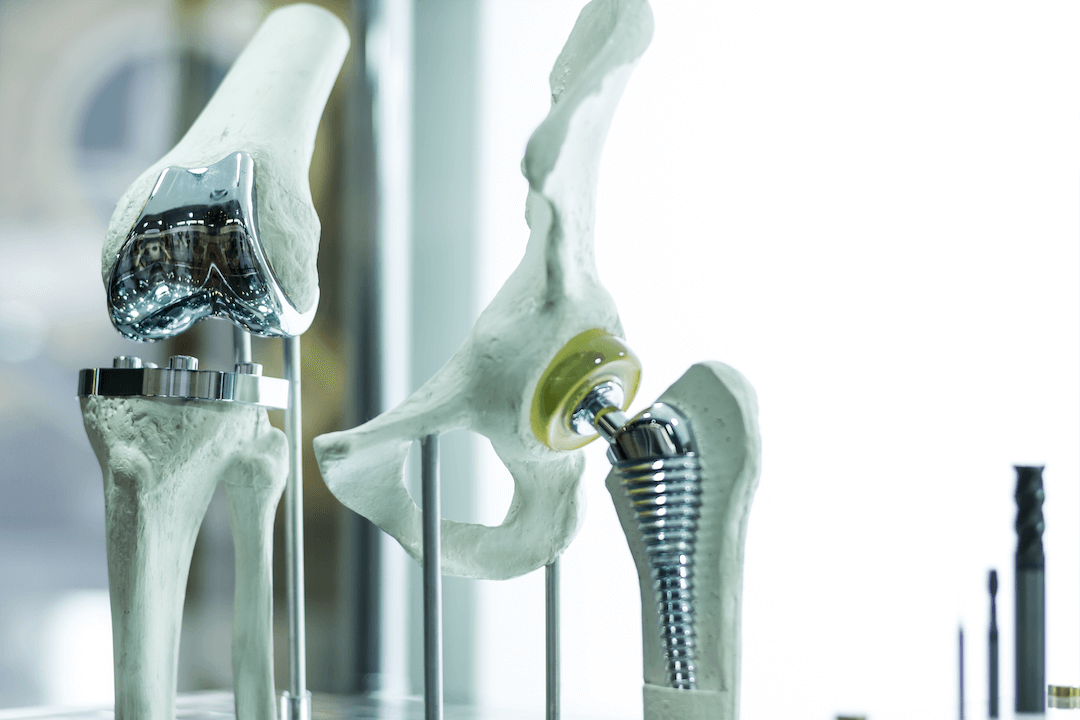

CUSTOM TRAUMA HIP CUP REPLACEMENT

Medical I Deburring, Descaling, Polishing

Bone fractures are often a result of an accident but can also be a side effect of getting older. Today it seems like everyone knows someone who has had either a partial, full or reconstructive hip replacement. In some severe cases, the hip bone needs to be stabilized as well as replacing the cup. Custom 3D printed or cast and machined components can be built from CT or MRI scans to perfectly match the patients’ pelvic contours. ISO Finishing used a multiple step cut and polish to remove any burrs and blend edges to reduce any opportunity for infection.