Expert Firearm Surface Finishing & Polishing

Gone are the days of the wild, wild west. Today’s firearm manufacturers push performance limits by incorporating exotic alloys, precision components and new means of manufacturing. The resulting firearms are safer, sleeker, perform better and last longer than ever before.

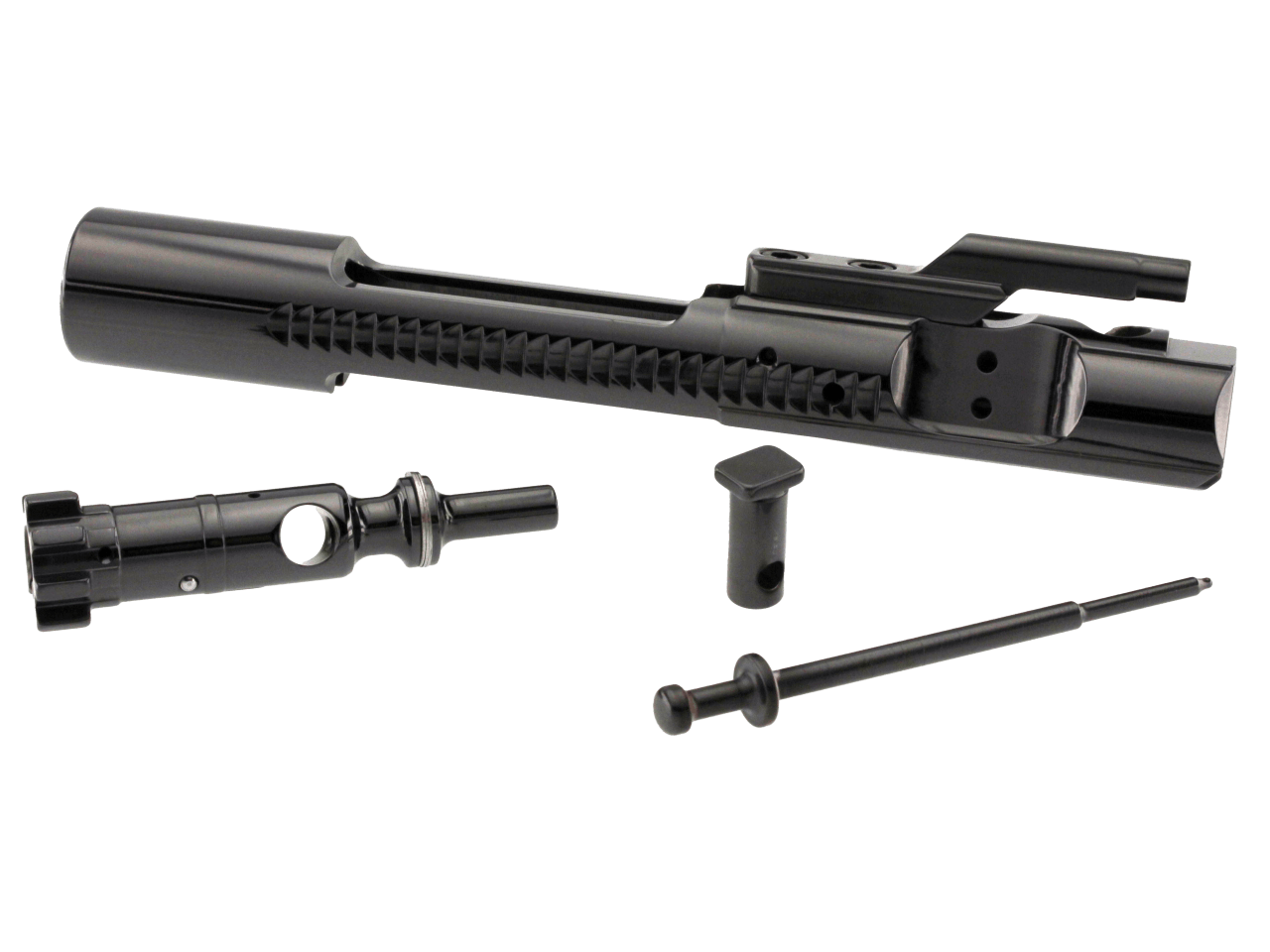

As a Federal Firearm Licensed (FFL) partner, ISO Finishing’s customized firearm finishing services complement both major and niche firearm manufacturers. ISO Finishing has surface finishing solutions and capacity for large production runs of firearm components such as gas rings, triggers and gun barrels. Additionally, we offer specialized gun finishing services in preparation for custom coating applications.

Resources

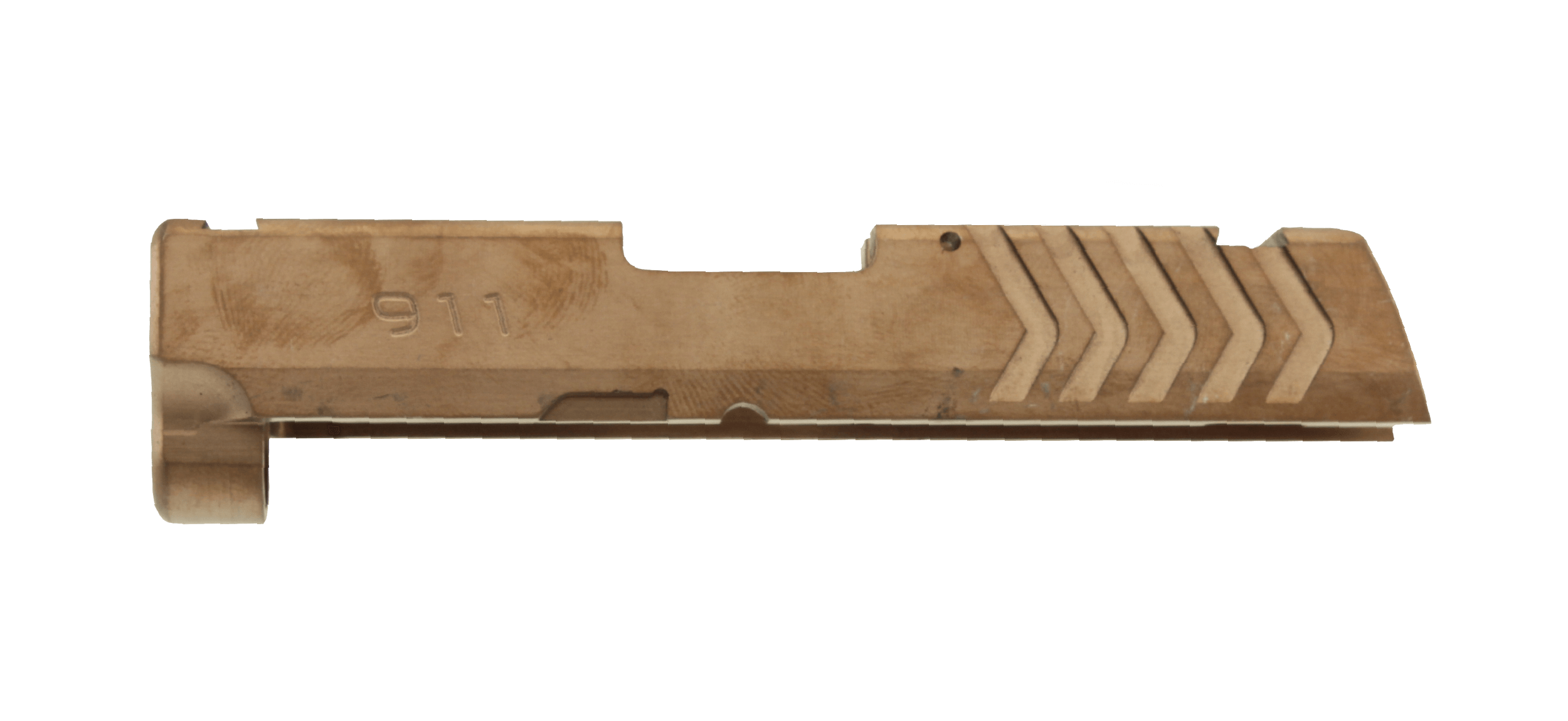

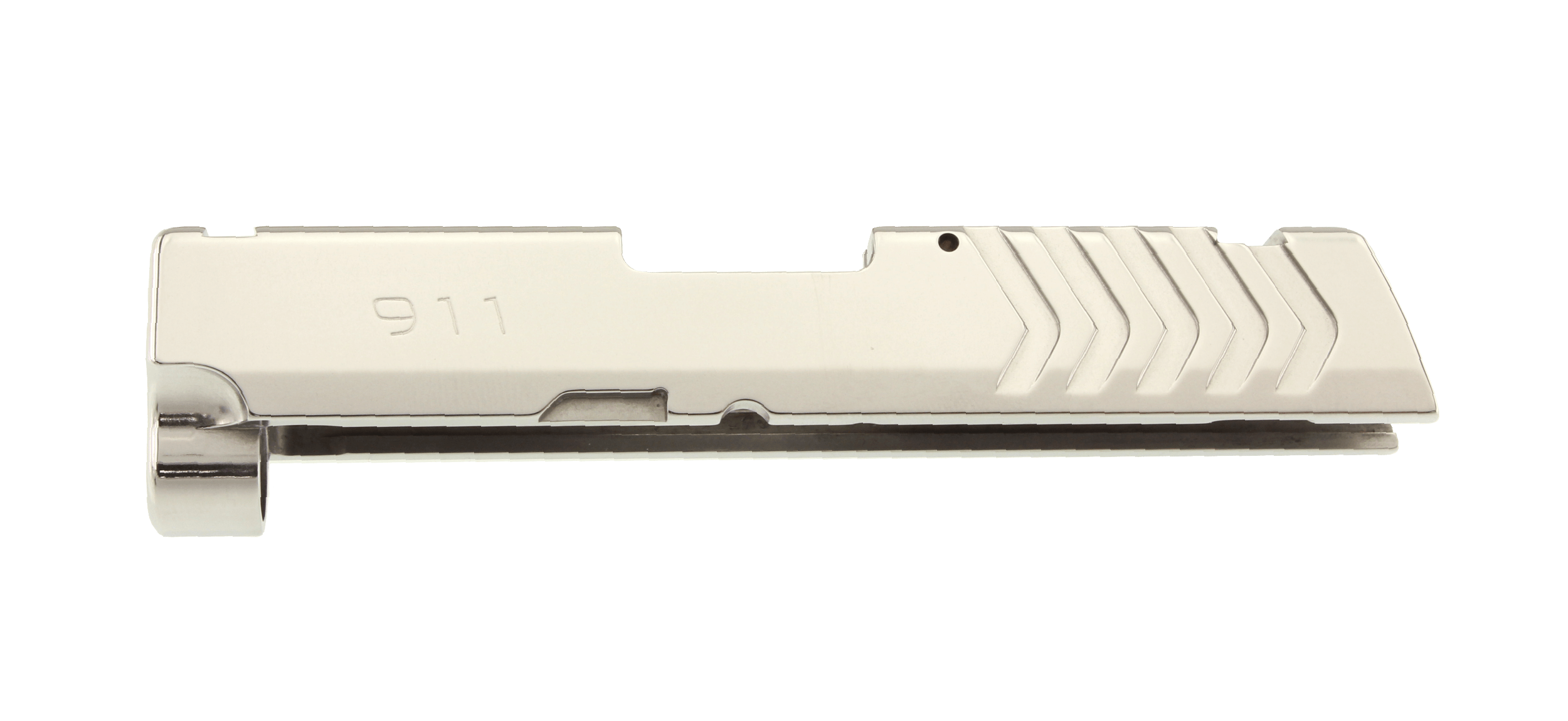

BEFORE & AFTER

SEMI-AUTO PISTOL SLIDE

Firearms I Deburring, Descaling, Polishing

Many of the components used in firearms today are heat treated to make the surface harder and more wear resistant. The downside of the process is the remaining brown or green heat treat scale which occurs from the quenching process. The scale is often rough and must be removed prior to any chroming or secondary coating can be applied. In the slide shown here, ISO Finishing was able to cut and polish the surface to a mirror finish ensuring the final coating met performance and customer expectations.