Surface Finishing Solutions for the Energy Sector

From solar to wind to hydroelectric power, the need for sustainable alternatives and more efficient use of existing resources drives engineers and manufacturers to bring new ideas, processes and solutions onto the energy horizon. ISO Finishing understands the regulatory and financial complexities facing companies manufacturing parts across the energy sector.

Partnering with clients, ISO Finishing creates customized, documented and repeatable surface finishing solutions on any material for:

- Solar

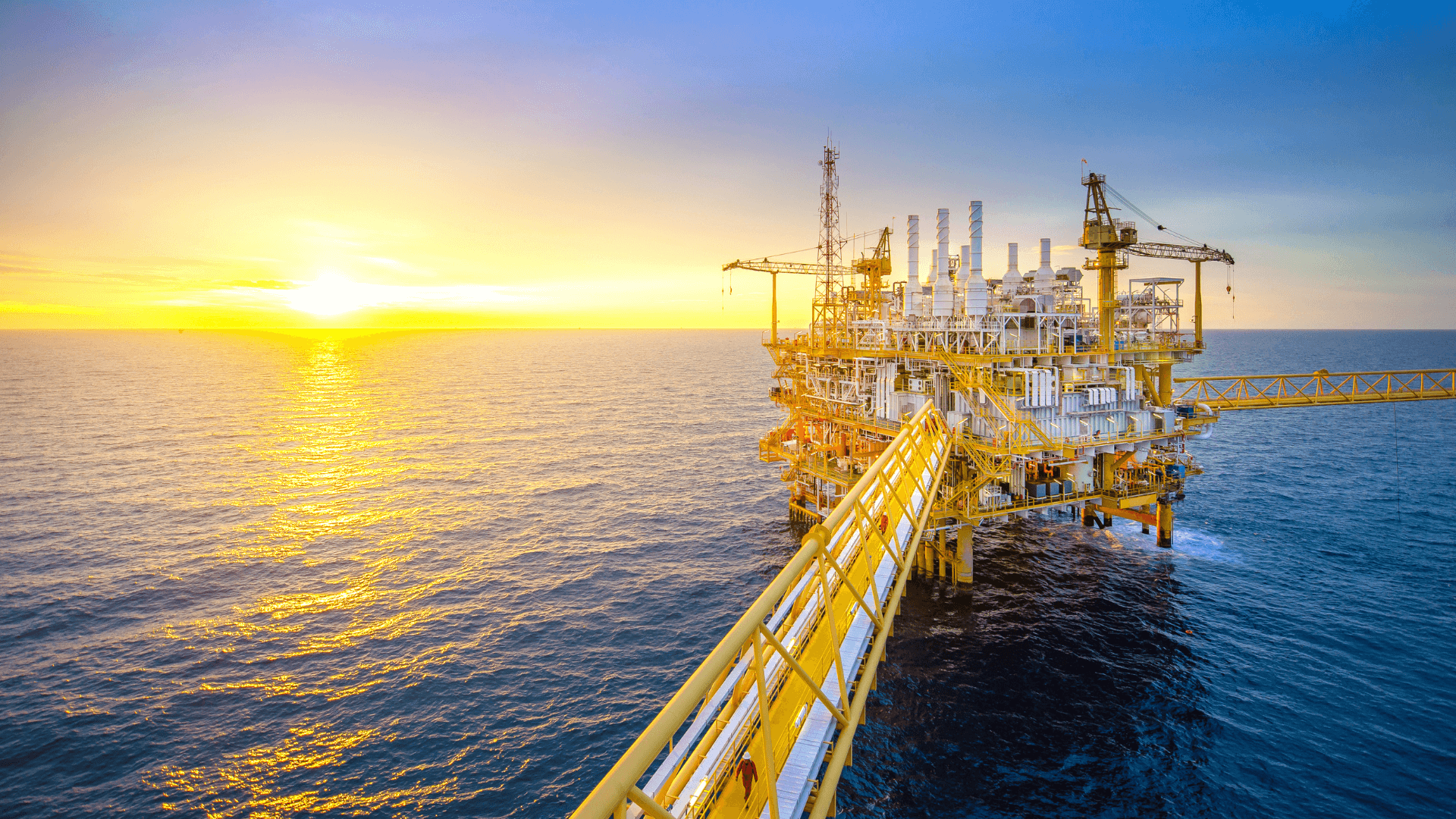

- Oil & Gas

- Wind Power

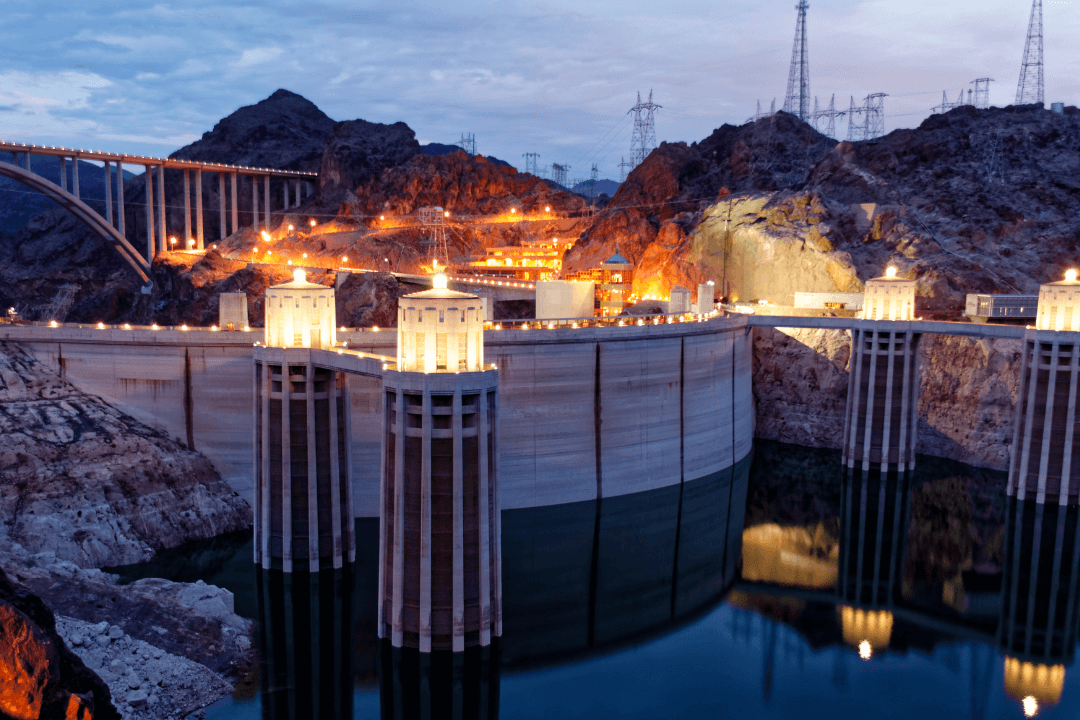

- Hydroelectric

- Nuclear

- Mining

By leveraging our knowledge in metallurgical and tribological fields, ISO Finishing is able to ensure each project is as productive as possible. ISO 9001:2015 certified, our surface finishing solutions are documented and repeatable, contributing to innovation and progress throughout all aspects of the energy sector.

Resources

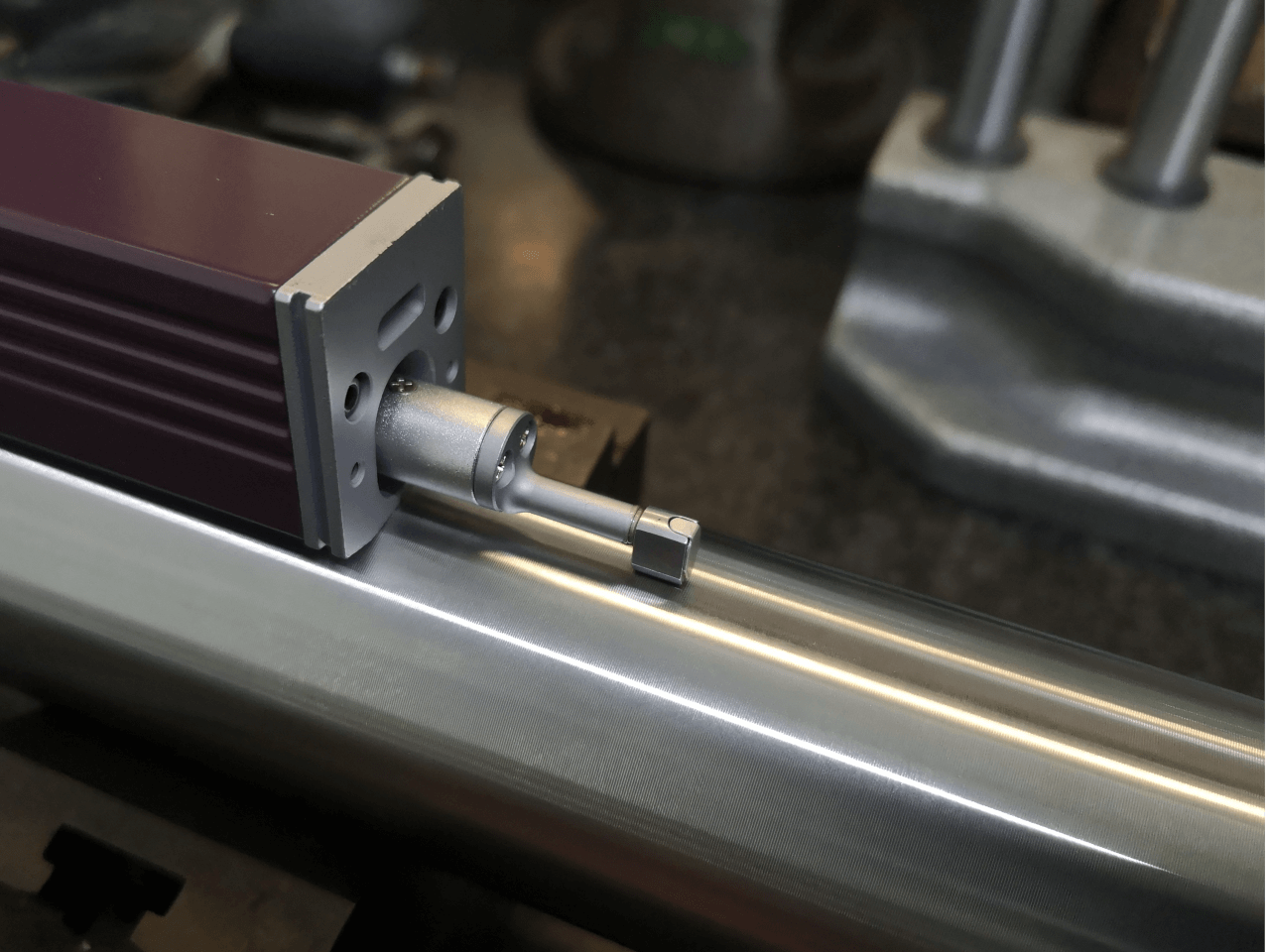

BEFORE & AFTER

INDUSTRIAL VALVE COMPONENT

Energy I Deburring, Polishing

Brass, bronze and other copper alloys have long been used for their corrosion resistance. But like any metal, given enough time and the correct conditions, they will begin to show signs of oxidation. As many of these alloyed components are chromed or nickel plated, it is essential to remove any oxidation prior to plating to ensure the best adhesion possible. In the example shown here, ISO Finishing performed a two-step cut and process to smooth out any residual machining lines and polish the surface to prepare it for plating.