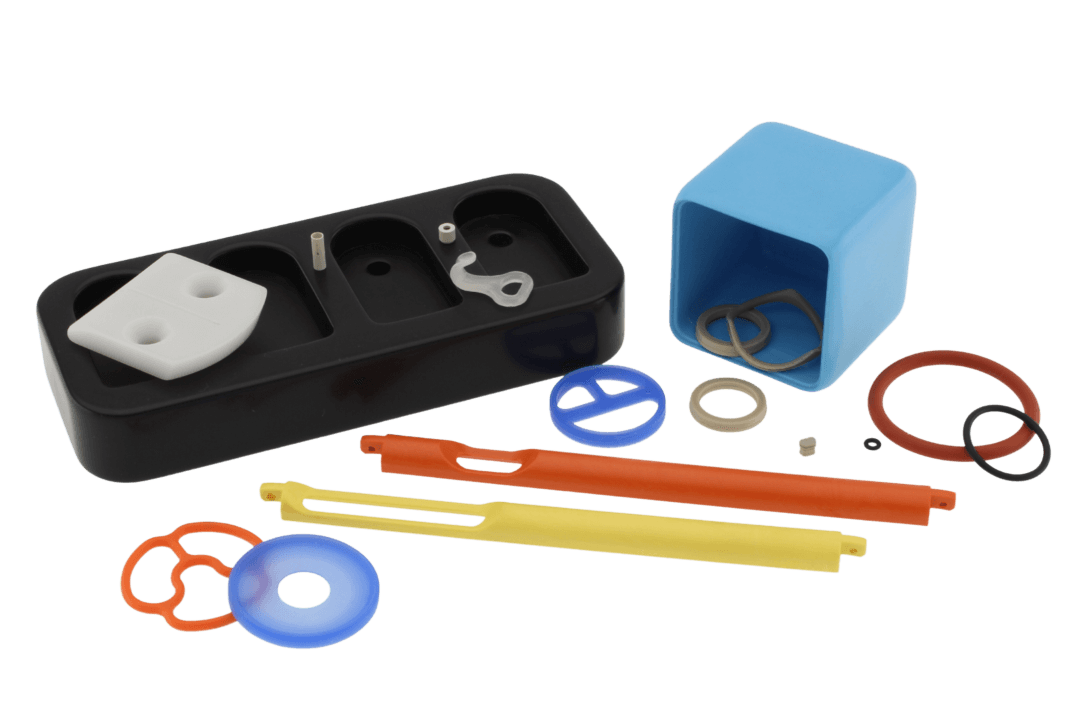

Residual Rubber, Metal & Plastic Flash Removal

Injection molding, casting and additive manufacturing allow for fast, precision production of parts in nearly limitless shapes, sizes and materials. However, these methods aren’t perfect. Flash, parting or build lines typically make parts unusable in their initial state. ISO Finishing’s deflashing services solve these challenges.

We use our mass finishing expertise for deflashing of rubber, plastic, metal alloys and other materials. Our surface finishing processes maintain initial geometries and are ideal for situations where heavier flash cannot be removed by cryogenic, chemical or other deflashing methods. We are also a great alternative for manufacturers looking for a more environmentally friendly deflashing option.

Through our innovative finishing solutions and collaboration with you, we formulate a process for each product and use your feedback to adjust the process — not the standard. The result is a customized, documented and repeatable process to ensure each finished product exceeds the most demanding standards.

BENEFITS OF DEFLASHING

- Product Uniformity

- Cost-Effective

- Dimensional Accuracy

- Increase Corrosion Resistance

- Improve Part Performance

- Decrease Potential For Part Failure

Fast Facts

- High-energy CBF deflashing does not leave residue on parts.

- Acrylic components can be deflashed without discoloration or cloudiness.

- Our mechanical deflashing processes simultaneously finish the part’s surface saving both time and money.