Metal & Plastic Burr Removal Services

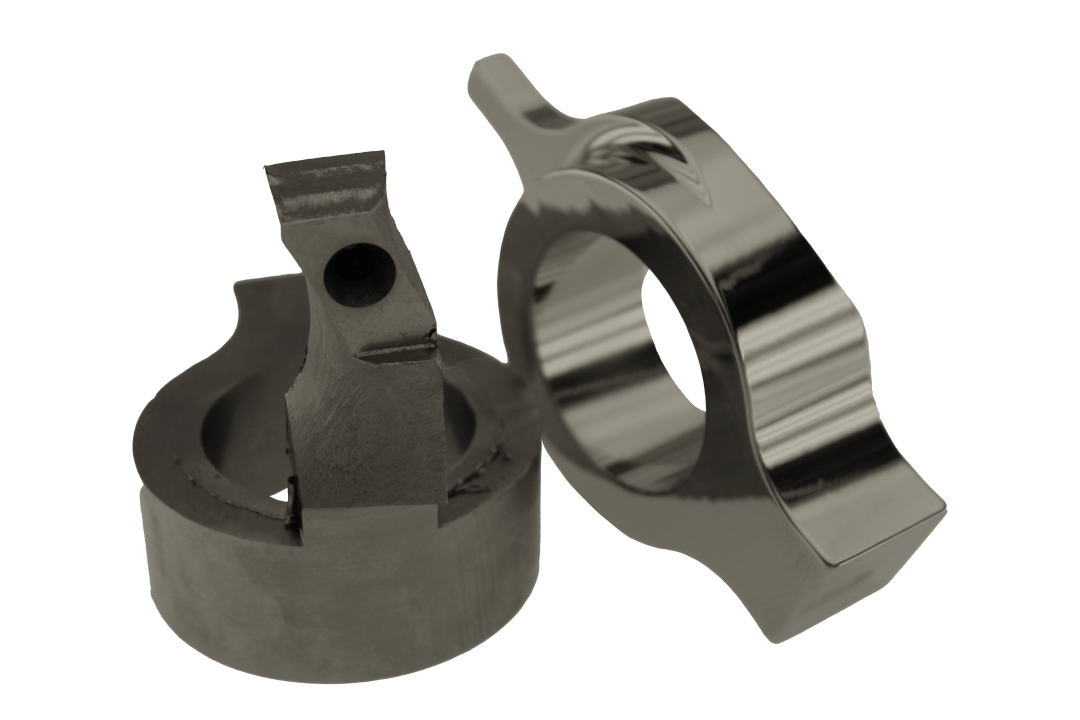

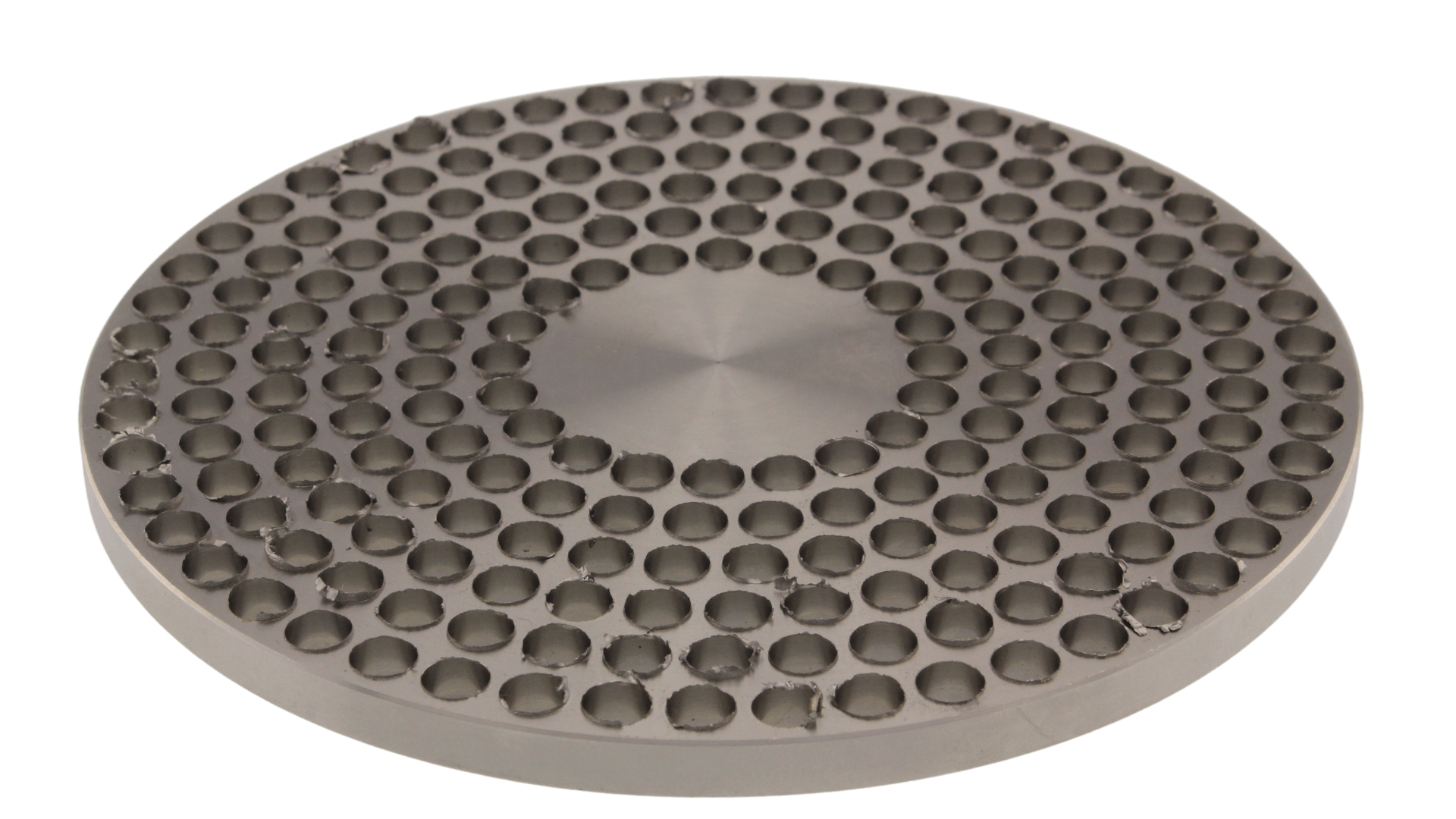

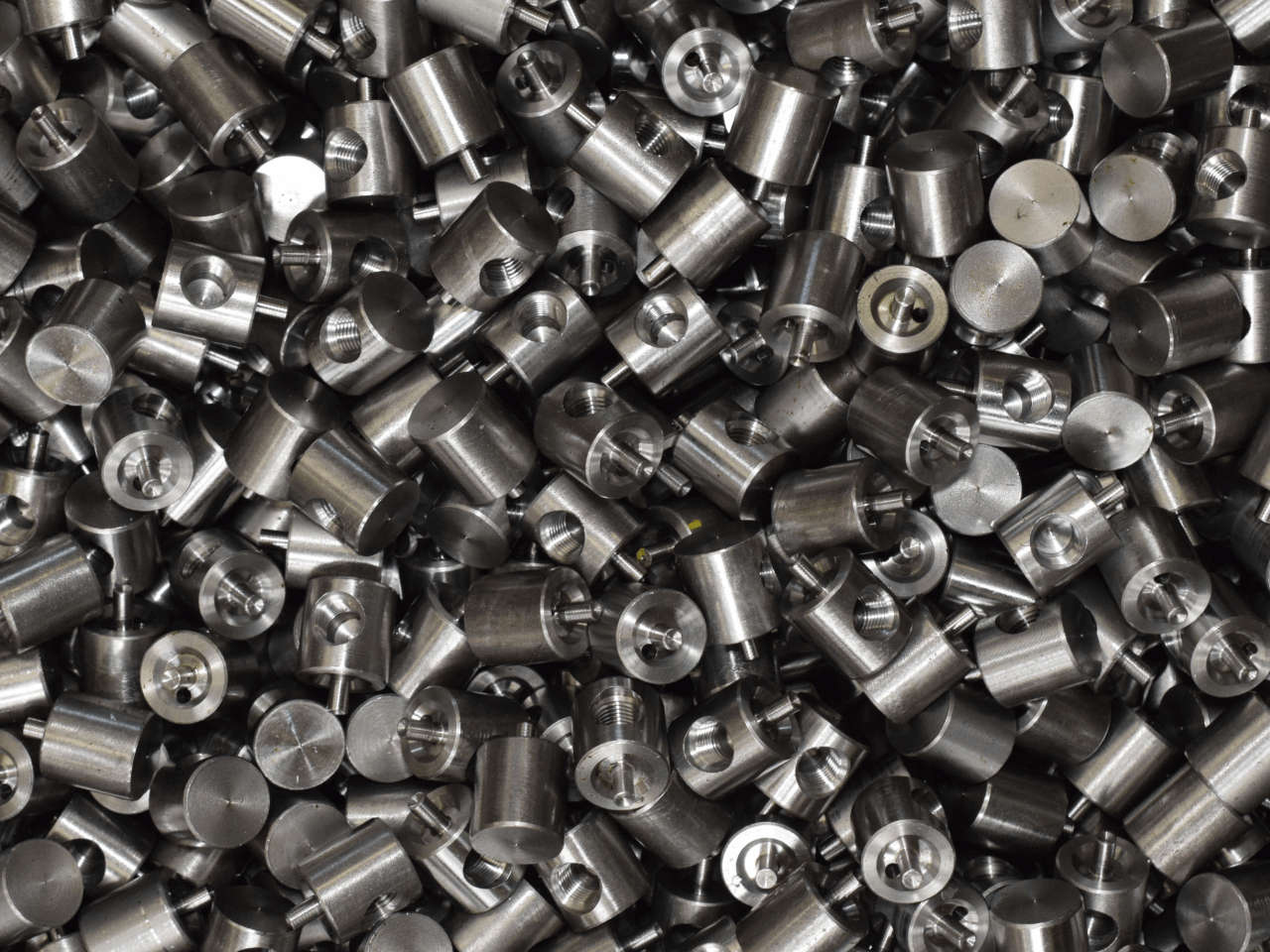

Manufacturers are all too familiar with burrs — the residual rough edges and protrusions left behind during the production process. Any method of cutting, machining or injection molding of parts can create sharp, raised or ragged edges. When left unfinished, these inconsistencies compromise part performance, impact part assembly and diminish the overall look and feel of a finished product.

Burr formation varies by type of material and method of manufacturing used. Some types of burrs include:

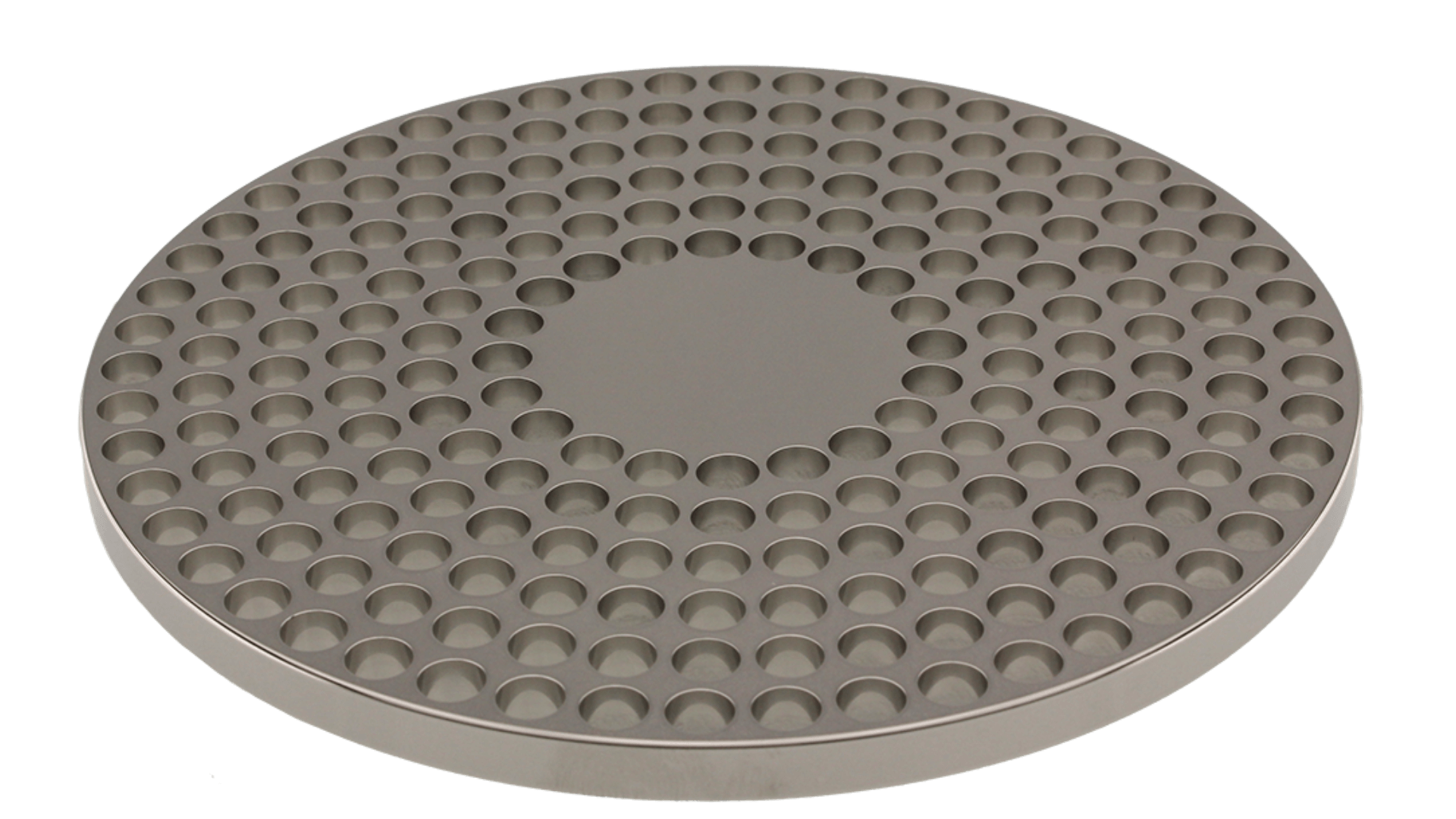

As a mass finishing industry leader, we offer deburring services on any material — including metal, rubber and plastic. Utilizing a combination of high-energy centrifugal barrel finishing (CBF) machines, vibratory deburring equipment and other ancillary finishing devices, we create processes that are more efficient and economical than manual metal burr removal. Our solutions are ideal for intricate components with the most exacting tolerances.

Through our innovative finishing solutions and collaboration with you, we formulate a process for each product and use your feedback to adjust the process — not the standard. The result is a customized, documented and repeatable process to ensure each finished product exceeds the most demanding standards.

BENEFITS OF DEBURRING

- Decrease Potential for Part Failure

- Improve Part Performance

- Increase Safety

- Promote Adhesion for Coating or Plating

- Enhance Surface Appearance

- Reduce Assembly Time

Fast Facts

- Mechanical deburring costs less than other deburring methods.

- Burrs can be minimized during part planning and design.

- There are more than 120 deburring processes.