Expert Surface Preparation Services

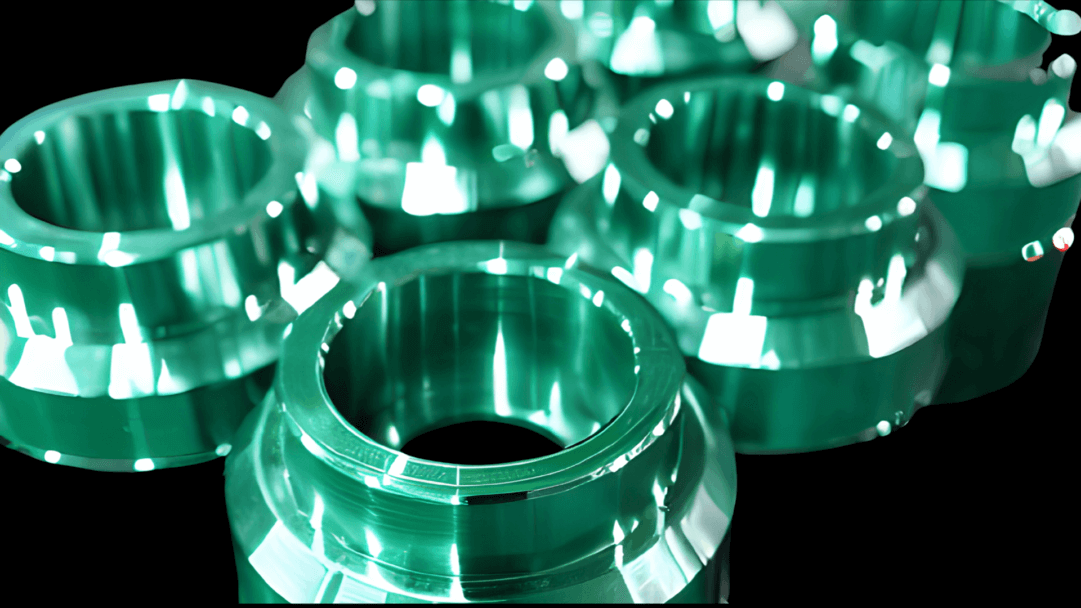

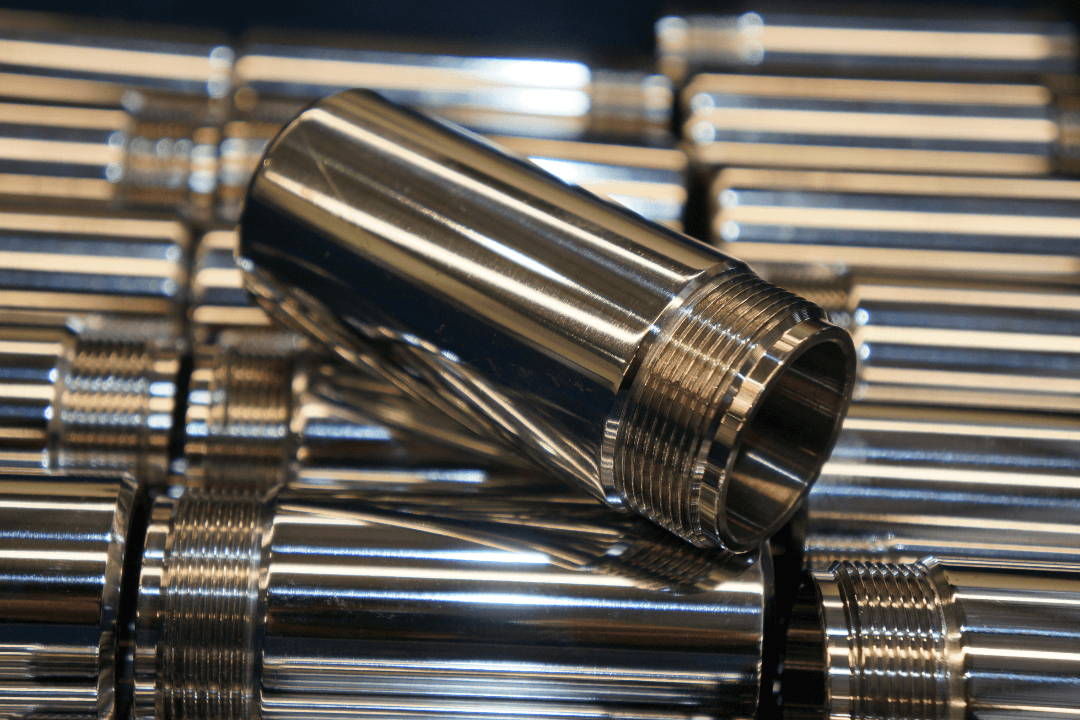

Engineers, machinists and manufacturers know all too well how proper surface preparation for plating, coating and anodizing can determine success or failure. Metal surface preparation eliminates imperfections and contaminants, enhances appearance, maintains dimensional stability and promotes greater adhesion for:

- Anodizing

- Chroming

- Nitriding

- Plating

- Powder coating

- Thermal Coating

- Thin Film Coating / DLC

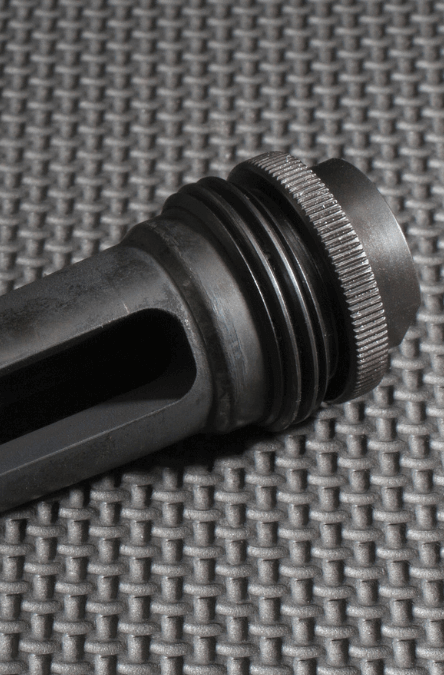

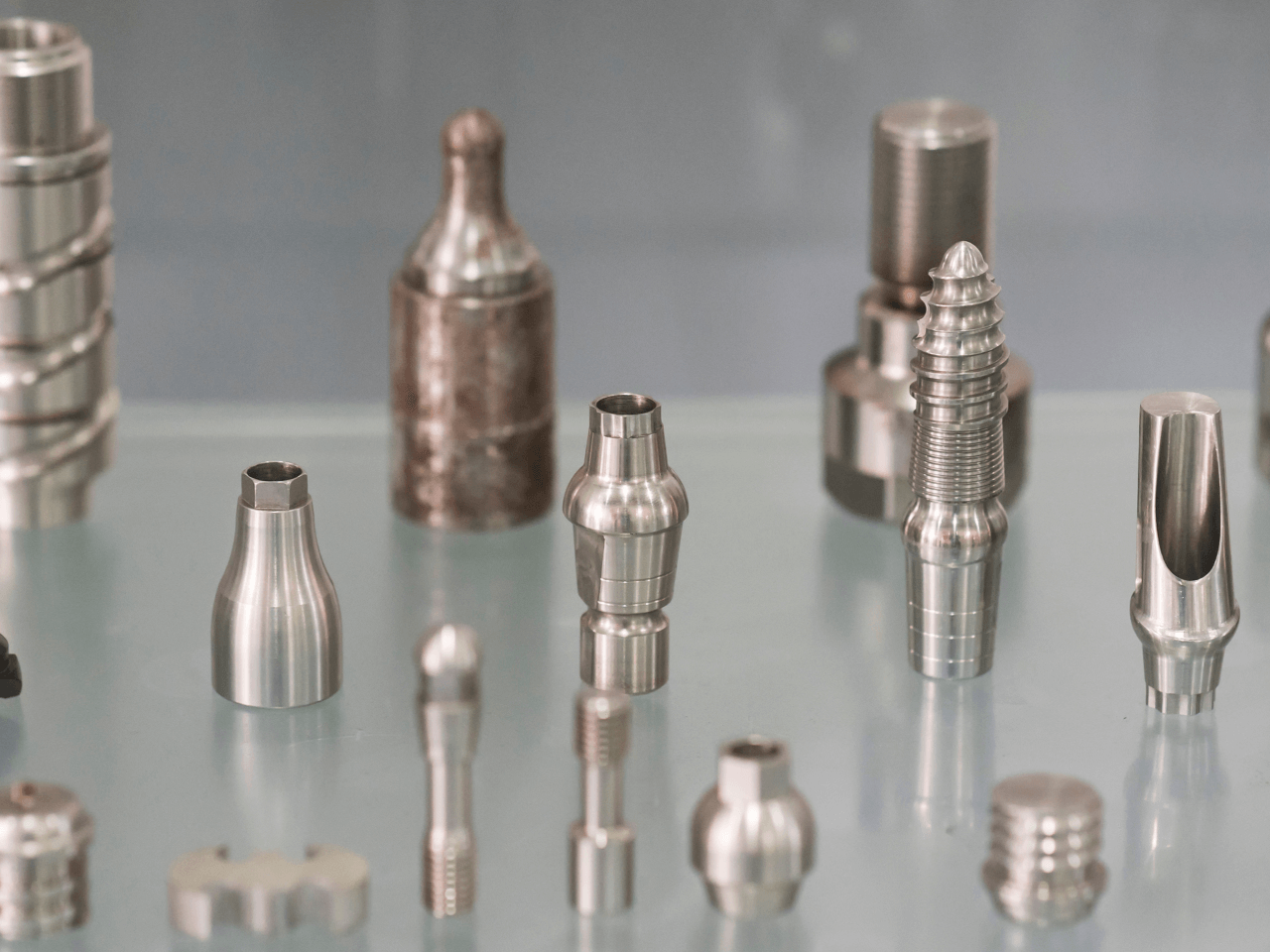

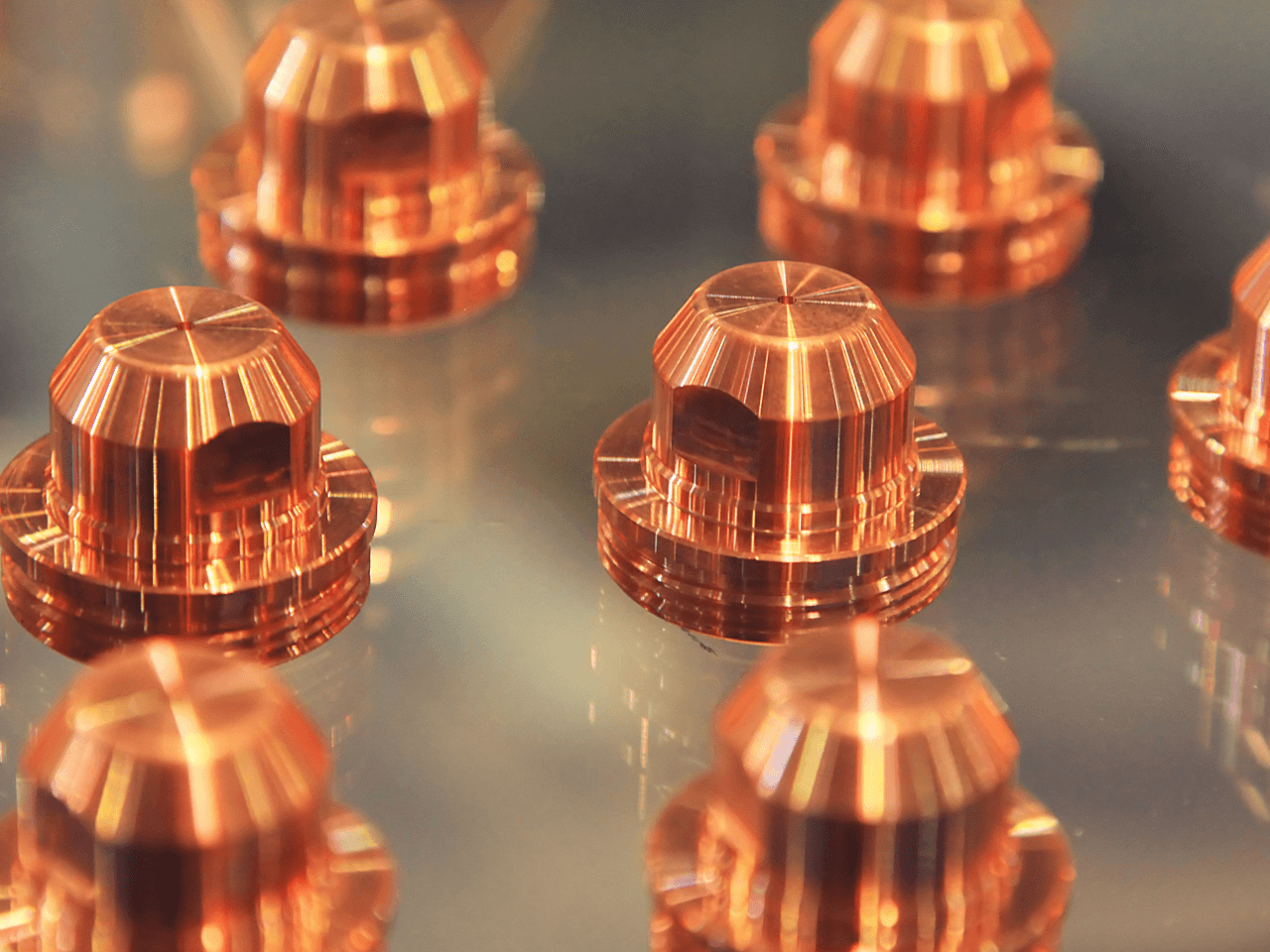

A thorough understanding of the material, manufacturing process, coating thickness and a part’s final intended use dictates the level of finishing needed. A combination of finishing processes including descaling, deburring, texturizing or polishing ensures products in any material are properly prepared for plating and coating.

With over 35 years of experience in metallurgy and finishing industries, the ISO Finishing team has the knowledge, experience and state-of-the-art technology to prepare the most intricate components.

Resources

BEFORE & AFTER

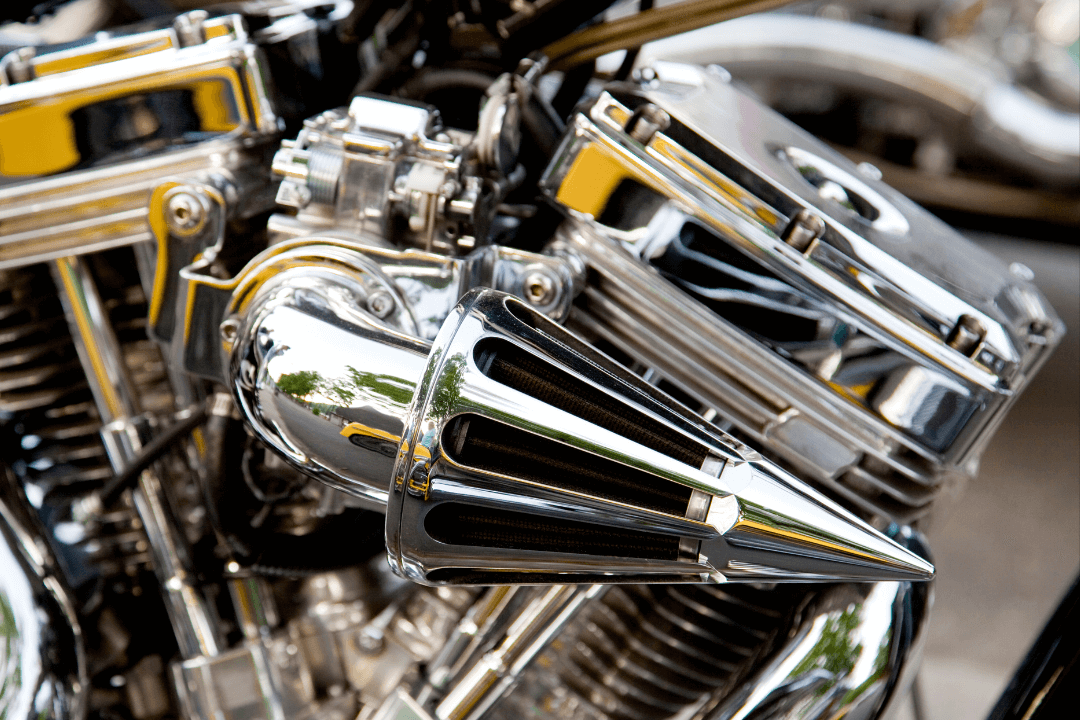

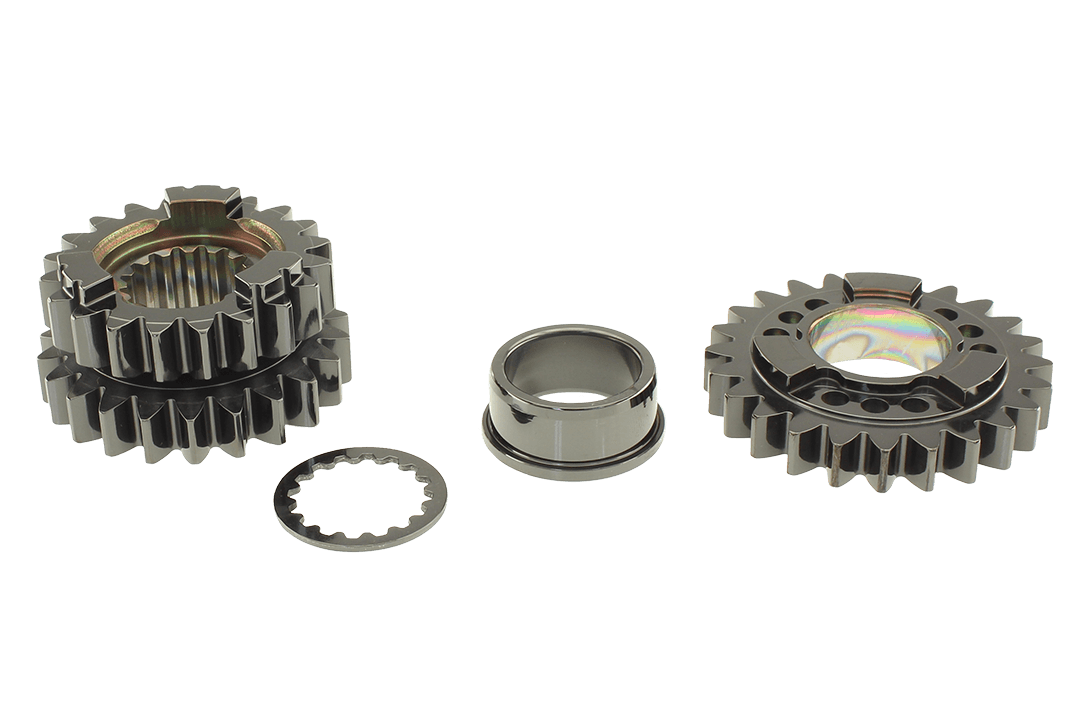

DRAG RACING FINAL GEAR

Coating & Plating I Deburring, Polishing

Funny Car and Top Fuel dragsters are always looking for any competitive edge to shave another few thousandths of a second off their time. Building bigger, more powerful engines and transferring more of the power to the pavement is the traditional school of thought to get it done. Reducing the amount of energy lost in the transfer of power is another way to win. The final gear shown here was cut and micro polished to prepare it for DLC coating. By polishing the surface, it allowed for a more uniform adhesion layer to ensure the performance and longevity of the friction reducing coating.