Centrifugal barrel finishing (CBF), or barrel tumbling, is a high-energy polishing method used to quickly and effectively improve the surface of parts. The process involves placing parts inside of a barrel which then rotates to remove burrs and create a superior finish.

Typically, a CBF machine is made up of two to four hexagonal barrels that are mounted on the outer edge of a turret. During the process, the turret is rotated in one direction while the barrels remain stationary. This creates high levels of pressure inside the barrel and causes the parts to slide against the side of the barrel. The sliding action of the parts against the barrel and media removes burrs, scale and creates a polished finish.

The benefits of centrifugal barrel finishing include:

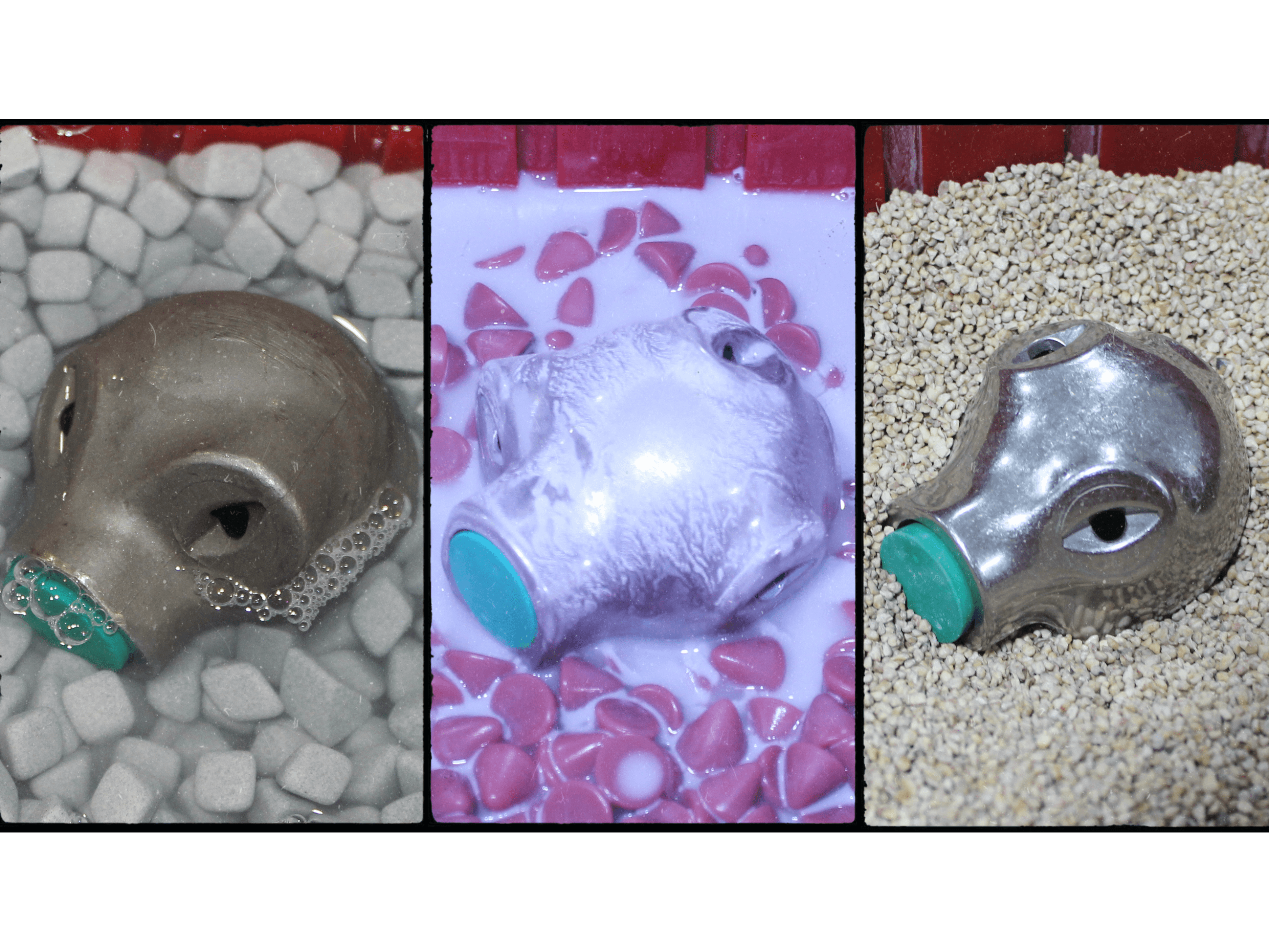

There are two types of centrifugal barrel finishing; wet barrel finishing and dry barrel finishing. While centrifugal barrel finishing utilizes both methods for finishing parts, each serves its own purpose.

Wet barrel finishing works well for finishing metal parts. While the barrels rotate (as mentioned above), the barrels for wet barrel finishing are usually horizontal in an octagonal or hexagonal shape. Due to their size and shape, these barrels are easier to load and unload, and are able to hold larger capacities. The barrels themselves are typically made of steel and often lined with a cushioning material which helps to protect the barrel and parts during finishing. Without it, the parts would become scratched or blackened due to the abrasive media.

During wet finishing, media, water and surfactant are mixed with the parts to deburr, form radii, polish and clean. The liquids carry the abrasive agents and help to protect the parts during the process. The length of the processing cycle varies by material and the degree of finishing required for the processed parts. When done, the parts are thoroughly rinsed with fresh water to prevent contamination, and dried.

Dry centrifugal barrel finishing (CBF) is most commonly used for finishing delicate plastic or metal parts. Rather than using liquid, dry barrel finishing utilizes abrasives like sand, corn cob grit, walnut shell grit, and pumice. Dry barrel finishing produces a smoother and higher finish upon completion.

There is not a right or wrong answer. Both finishing processes create a similar finished effect, quickly and efficiently. The customer’s finishing requirements often dictates the finishing process used.

With our documented and repeatable processes, ISO Finishing delivers superior surface finishes for all industries and material types. Let us show you how our finish will be your finish. Let us show you what we can do.

LET’S GET IT FINISHED.