Surface Finishing Solutions for Exact Requirements

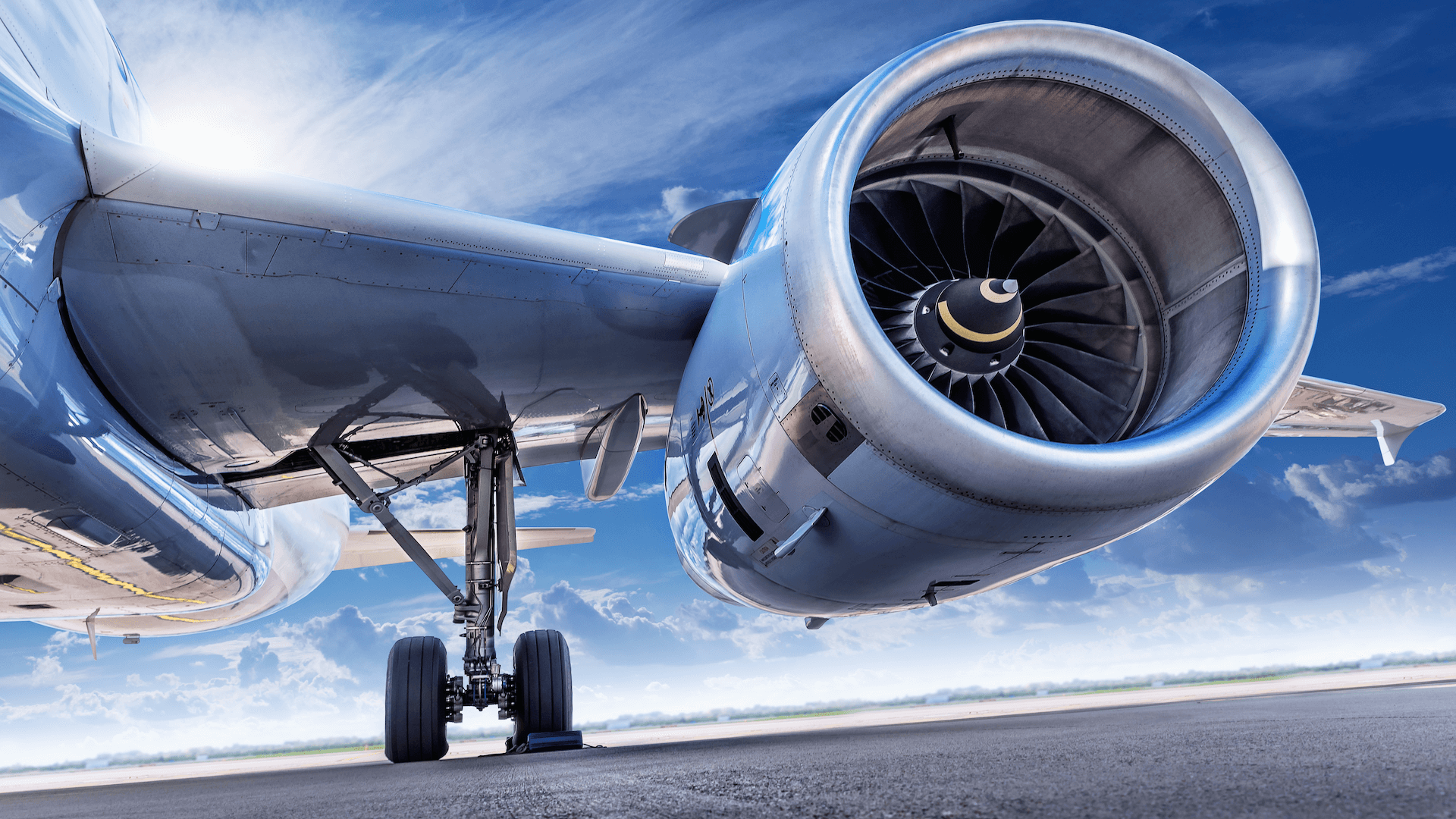

From aileron actuators and turbine blades to instrument panels and all types of metal and non-metallic parts, today’s aerospace and aviation components are intricate and complex. They must be lighter, stronger, more resistant to part fatigue and corrosion and able to withstand ever-changing conditions. Refined alloys of titanium, aluminum and stainless steel provide solutions to meet these challenges, but can be difficult to machine and finish — that’s where ISO Finishing steps in.

As an ISO 9001:2015 certified and CAGE Code registered company, ISO Finishing is capable of designing aerospace finishing processes to deliver a consistent, uniform surface finish prepared for any downstream processes or assembly.

Combining metallurgical and tribological knowledge with extensive experience, quality control and documentation ensures each part meets your exact print specifications.

Resources

BEFORE & AFTER

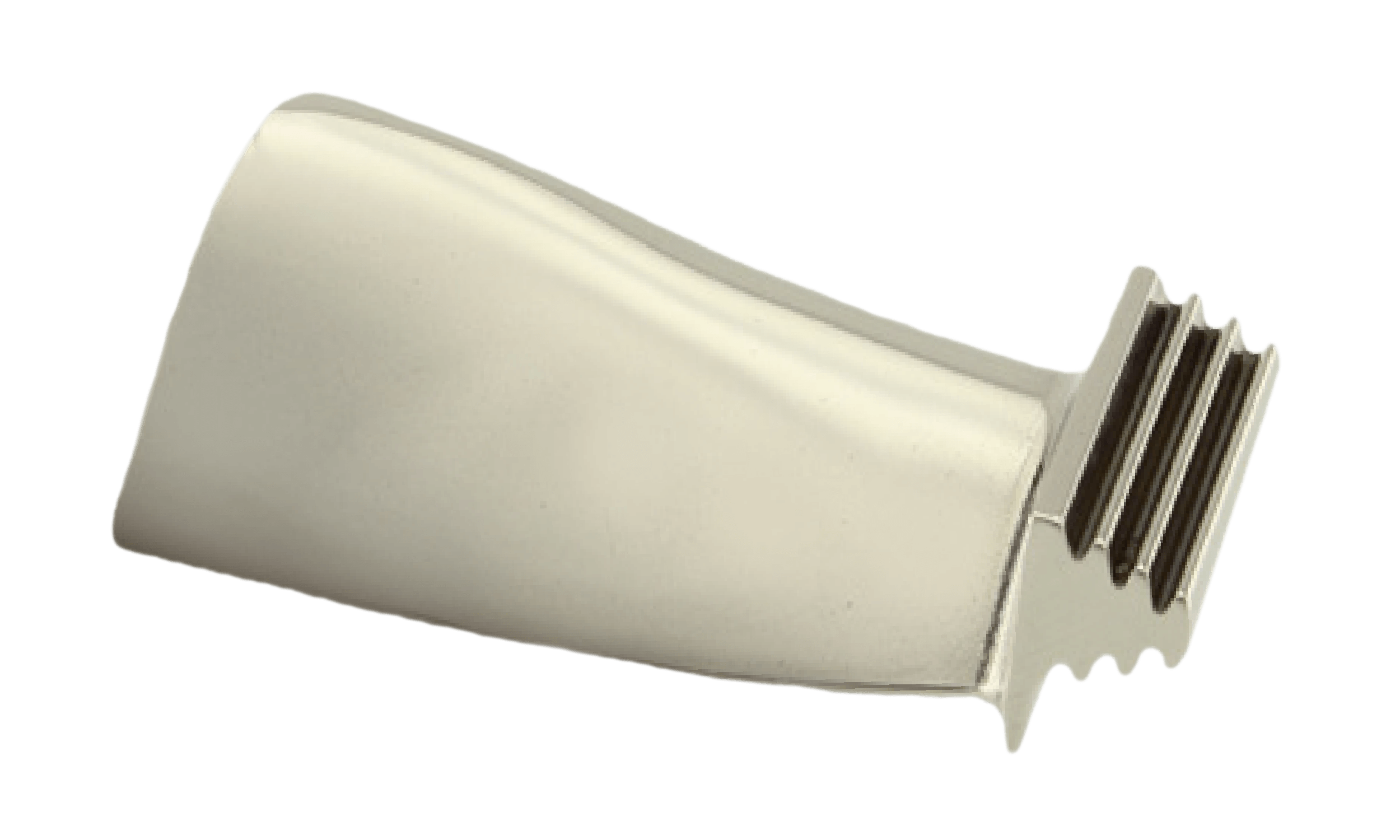

ELECTRICITY PRODUCING NATURAL GAS TURBINE BLADE

Aerospace & Aviation I Descaling, Polishing

Engineers have designed the blades of many types of turbines to be interchangeable. As one blade becomes damaged or worn it can simply be swapped out with another to get the unit back up and running as quickly as possible. Obsolete or out of production components, like the one shown here, can be refurbished and put back into production, saving the client money and extending the useful life of the generator.