Premier Post Processing and Surface Finishing Solutions

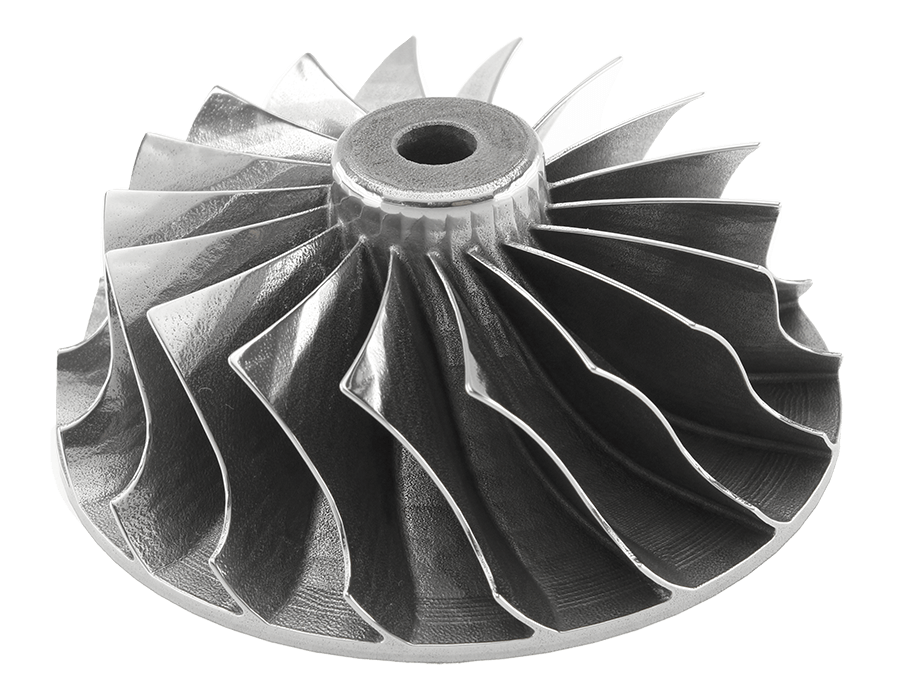

The evolution of 3D printing techniques used by additive manufacturing has changed the manufacturing landscape, allowing for the rapid creation of three-dimensional prototypes and fully functional parts in just a fraction of the time without the expense of tooling.

Designed in CAD, parts are built layer upon layer, with material being added only when and where necessary. Complex parts can be produced quickly, less expensively and with greater precision in a wide variety of materials including metals, polymers and ceramics.

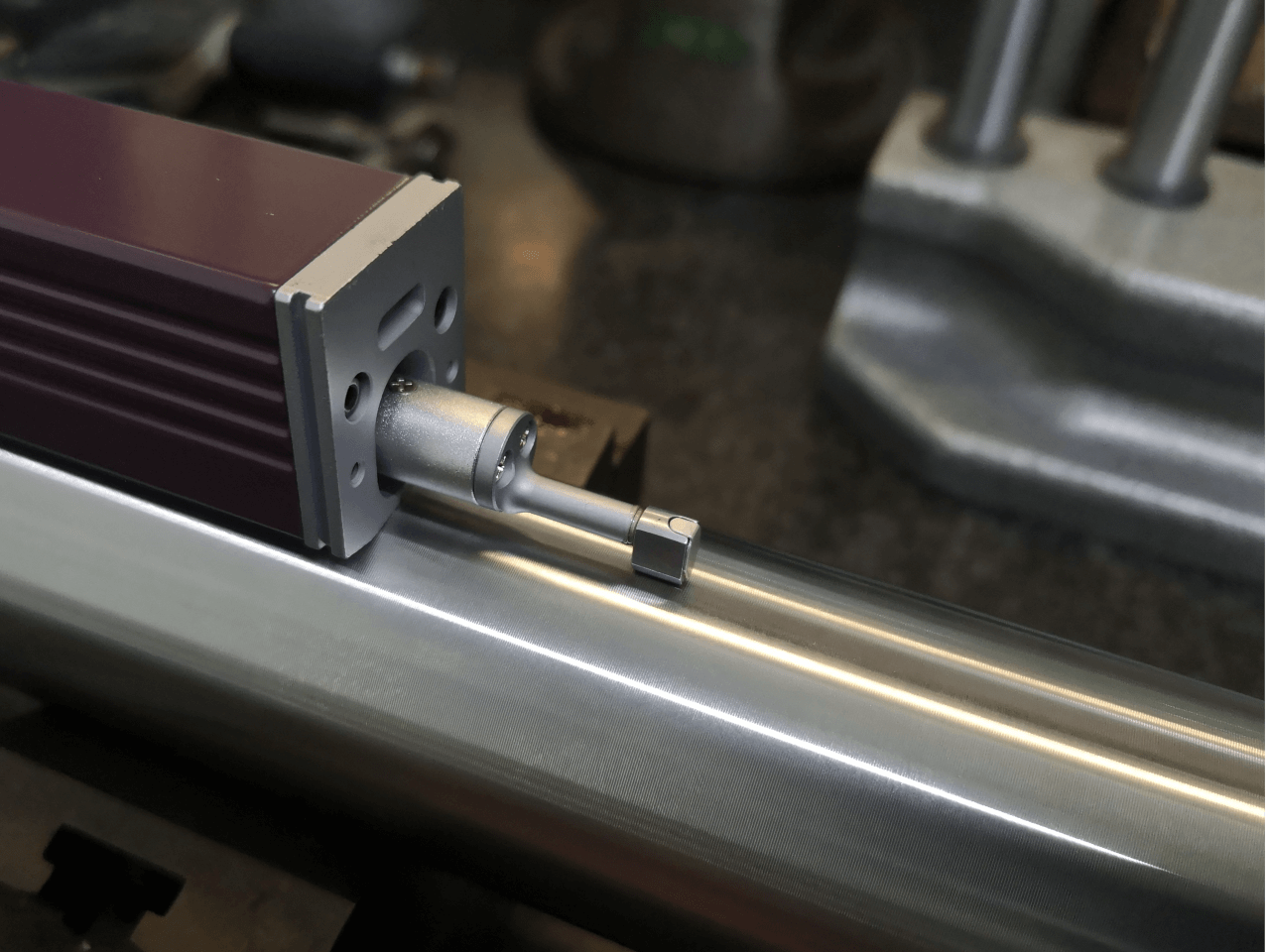

While additive manufacturing is a great alternative to traditional methods, 3D printed parts require some level of post processing. By removing support structures, flashing and refining physical characteristics, overall part performance is improved. ISO Finishing has the experience to create an additive manufacturing surface finish to meet precise requirements for companies in any industry.

Resources

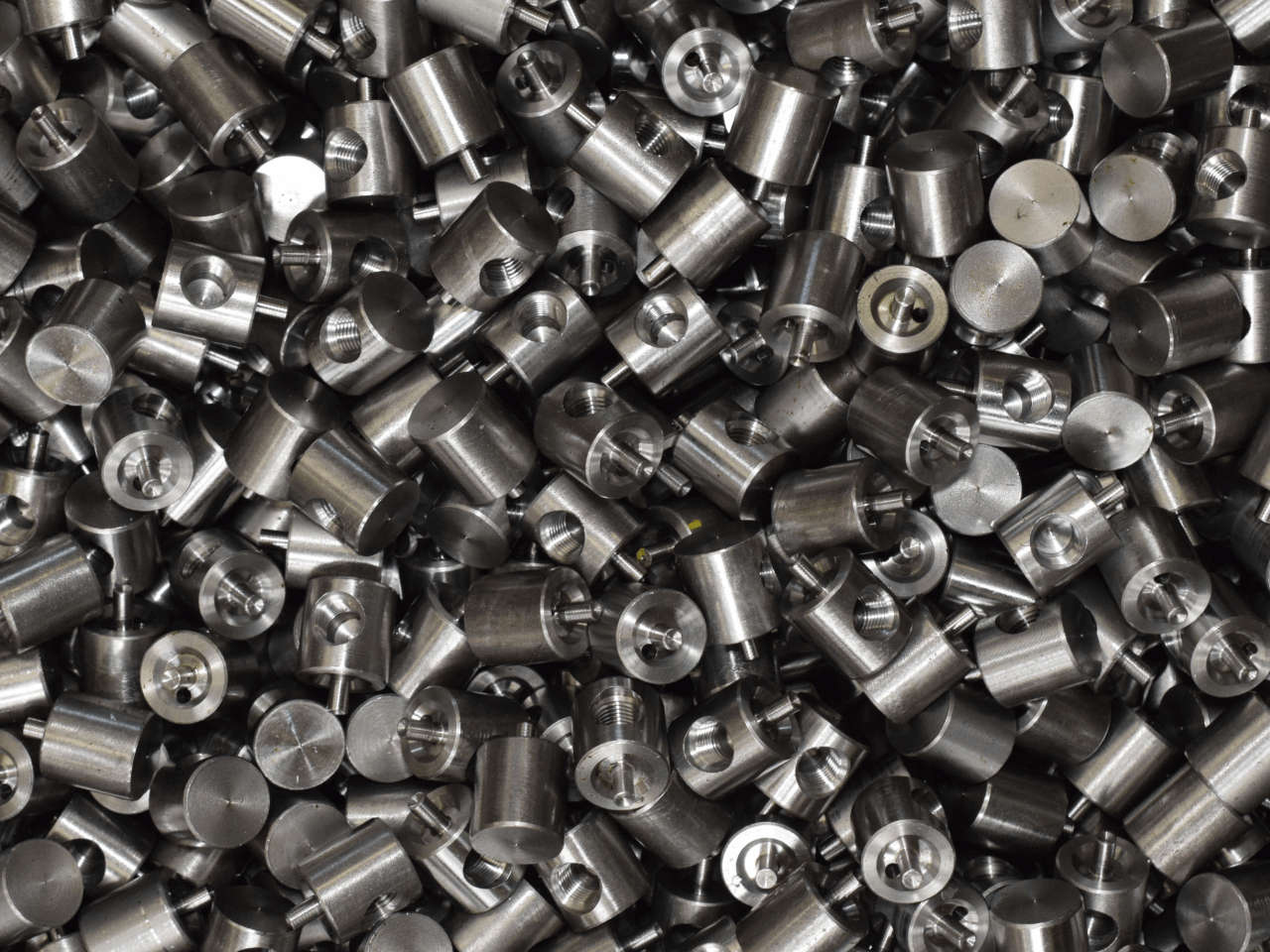

BEFORE & AFTER

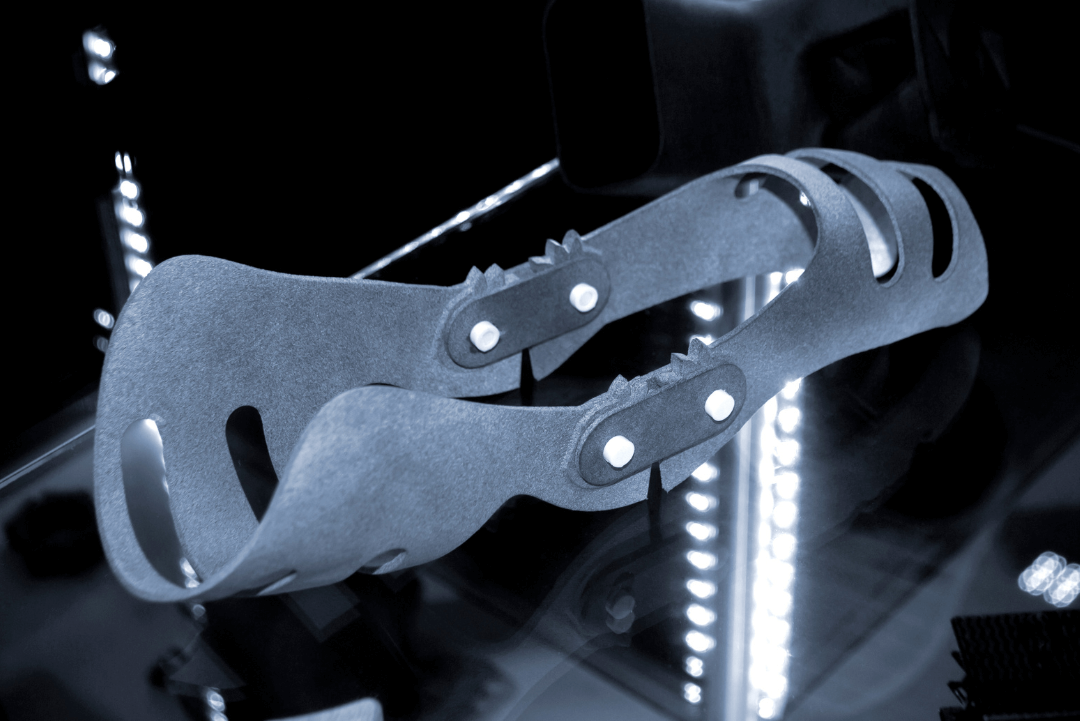

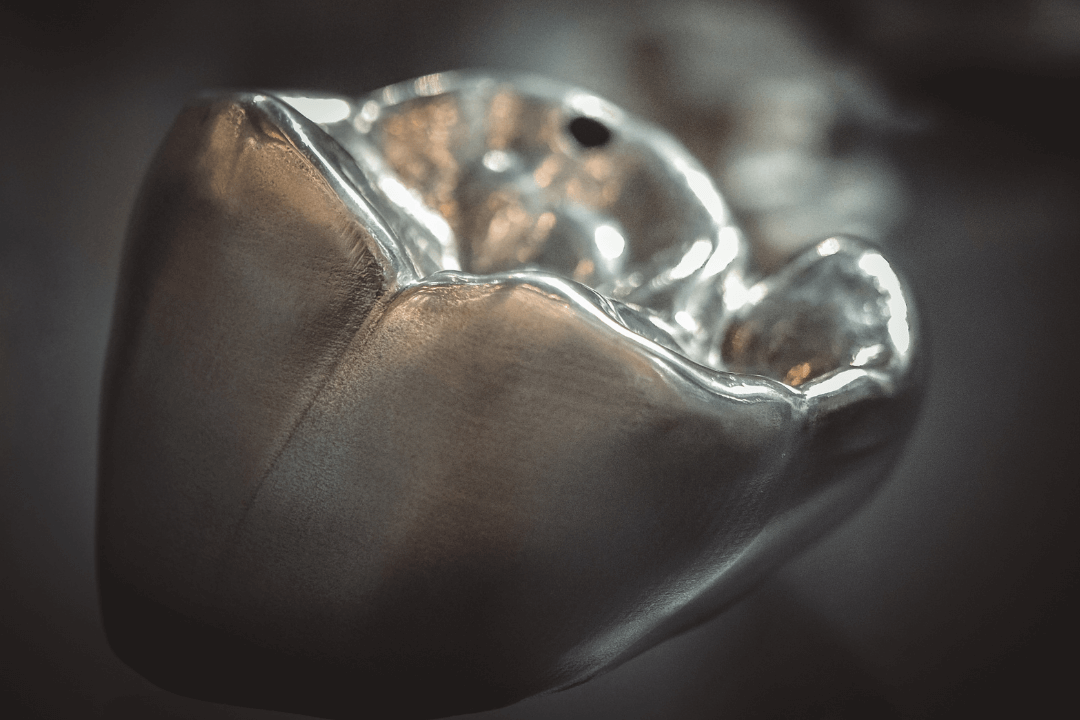

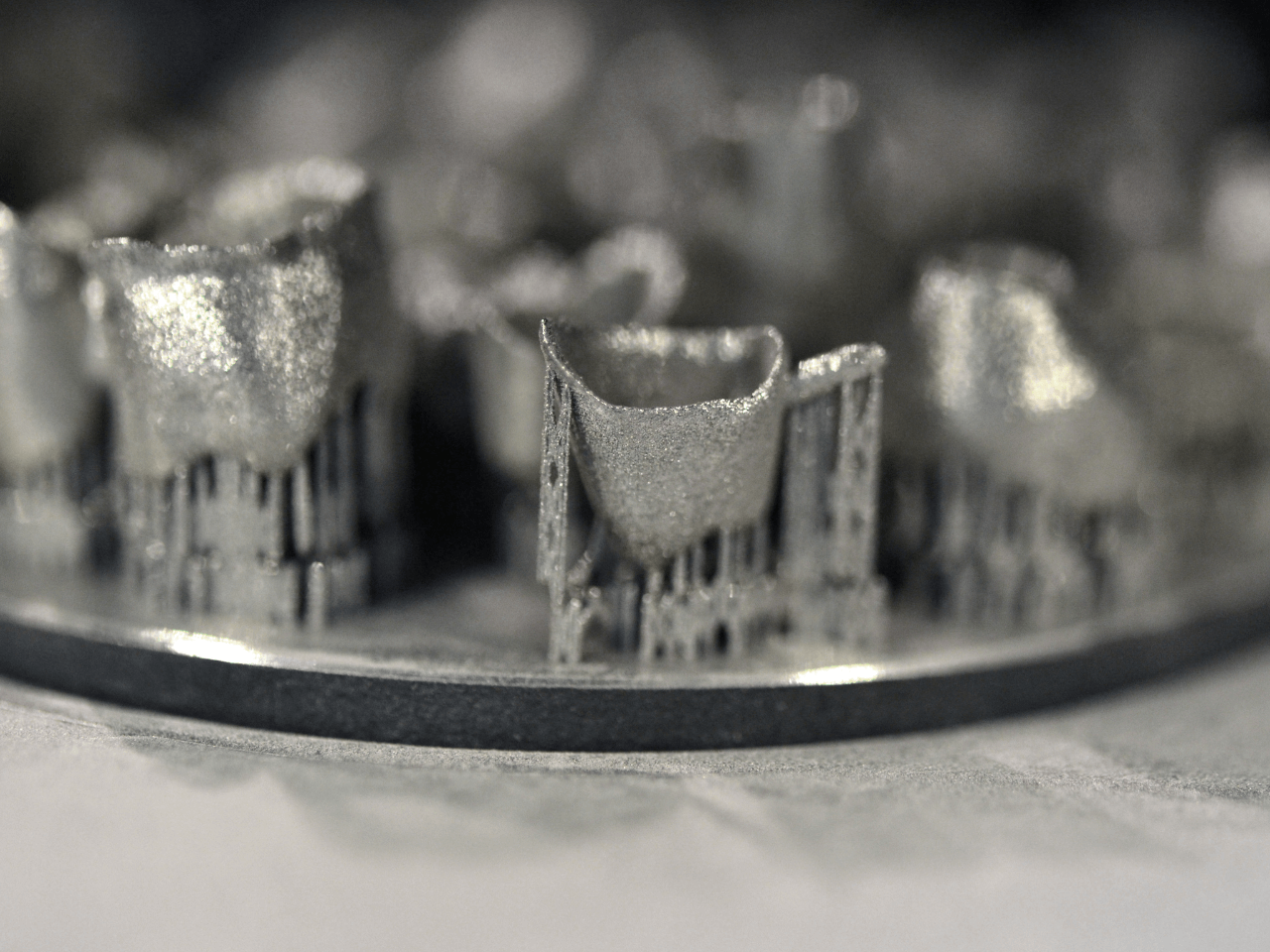

3D PRINTED TITANIUM WATCH BAND

Additive Manufacturing I Descaling, Polishing

Advancements in additive manufacturing have made it possible to make anything imaginable. The precision and accuracy of our clients’ printer made it possible for the band to articulate without any pins holding the band together. Even though the parts were made from recycled powder, we were able to cut and polish the band as printed to make a unique surface finish to complement any watch.