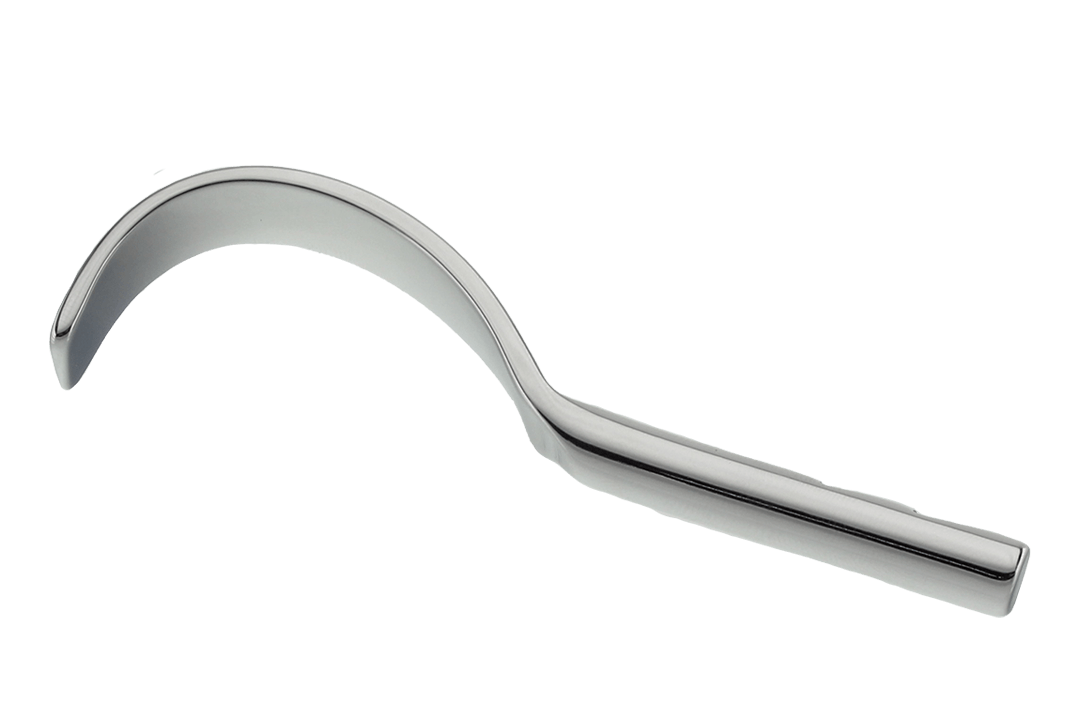

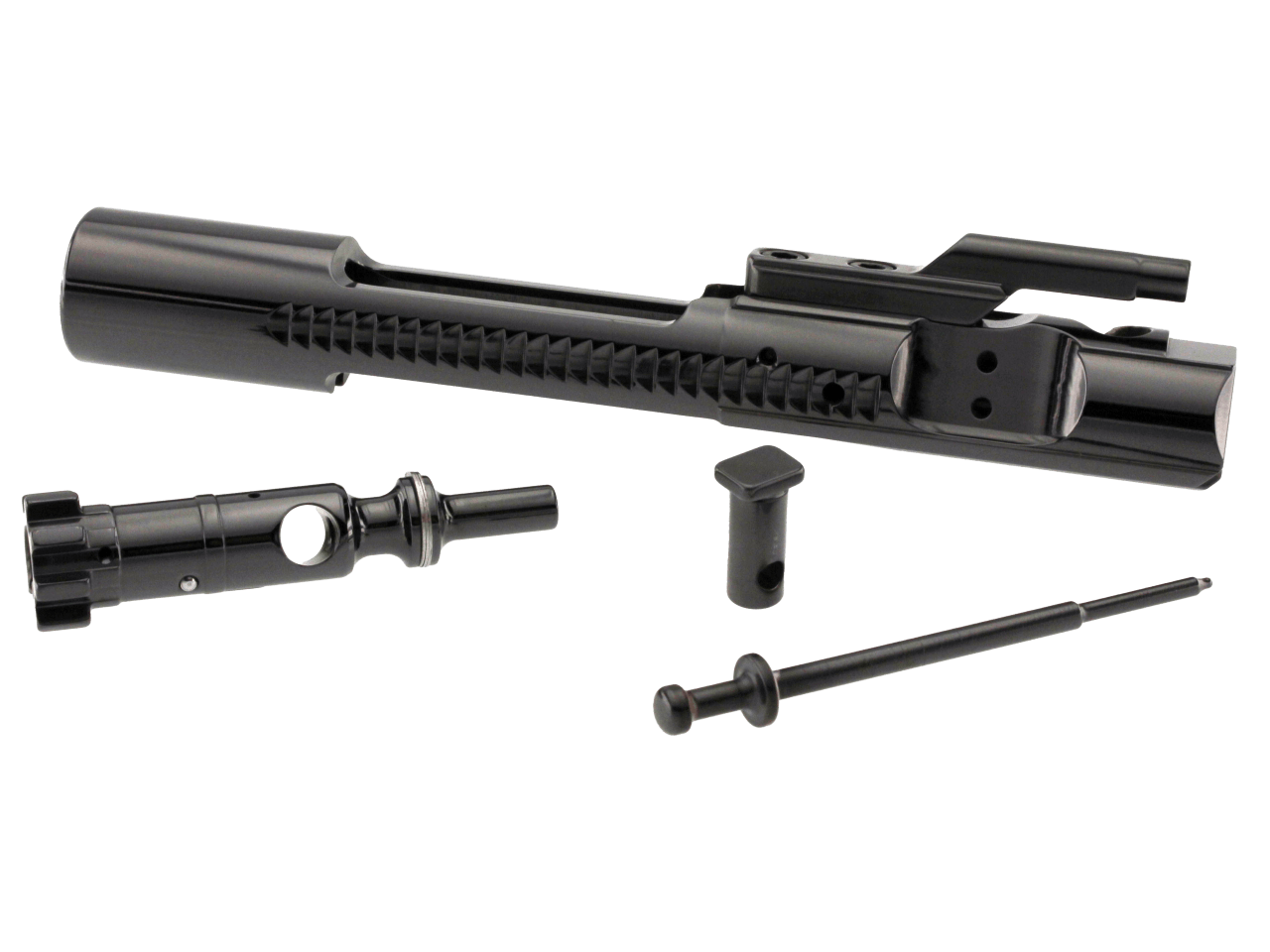

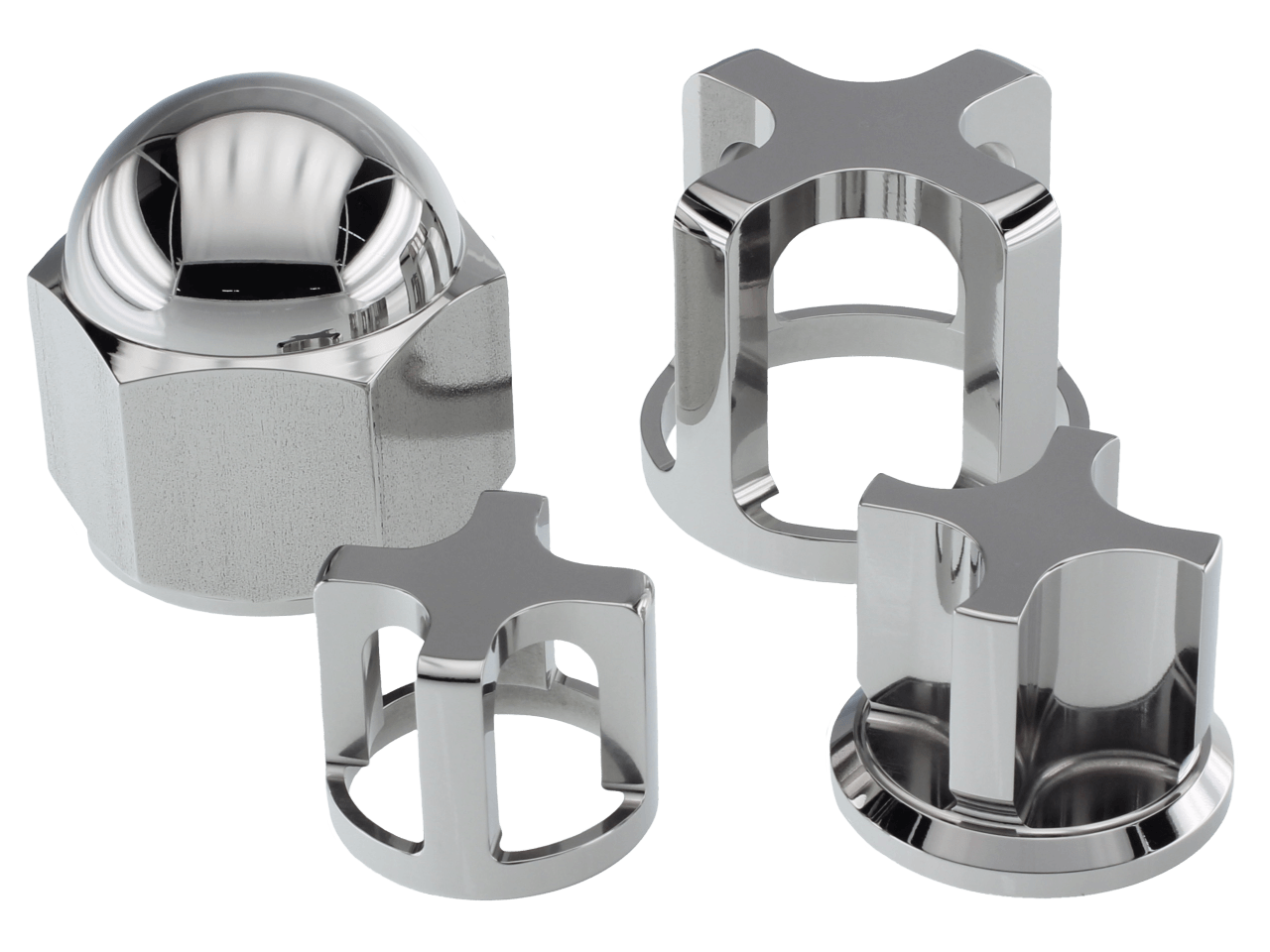

Heat Treat Scale Removal Services

When metals are heated during thermal treatments and exposed to oxygen, a layer of oxide forms on or very near the surface. Known as scaling, the heavy, thick layer discolors the metal and must be removed prior to subsequent manufacturing processes such as:

- Plating

- Thin Film Application

- Powder Coating

- Welding

Descaling, also known as metal oxidation removal, is essential for steel alloys, aluminum, titanium and other metals intended for medical, aerospace, food service or other critical environments where total cleanliness is essential.

Our mass finishing descaling services are often more economical than other descaling methods and are a great option for companies looking for an alternative to the harsh chemicals used in other mass finishing descaling methods.

Through our innovative finishing solutions and collaboration with you, we formulate a process for each product and use your feedback to adjust the process – not the standard. The result is a customized, documented and repeatable process to ensure each finished product exceeds the most demanding standards.

BENEFITS OF DESCALING

- Decrease Potential For Part Failure

- Lower Surface RA

- Cost-Effective

- Surface Uniformity

- Better Coating Adhesion

- Reduction Of Micro-Pitting

Fast Facts

- 1-3% of a material’s surface is lost to scaling during thermal processing.

- Removing scale reduces potential for further oxidation.

- Unlike other heat treat removal and descaling options, CBF does not change the material properties.