ISO Finishing takes great pride in polishing solutions for cast, molded, machined, fabricated, and 3D printed components. With so much attention to detail in the isotropic finishing process, ensuring the parts arrive at their destination undamaged is essential. Customers expect their parts to arrive in the best condition possible. While there are some things we can’t always plan for, proper care in how a part is packaged for shipment is key to preventing unwanted damage. Continue reading to learn about the many benefits of properly packaged parts shipped to and from our facility.

Parts are Protected

There is a lot of time and money invested in polishing the surface of parts, so ensuring they remain free of damage is crucial. Proper packaging keeps parts secure during shipping so they do not slide around. This diminishes the risk of part impingement occurring and keeps the integrity of the newly finished surface intact.

Protects Against the Weather

High humidity, extreme changes in temperature, and wet weather can have a negative impact on the shipping process. Packaging products with these conditions in mind will limit the effect weather will have on shipped parts. Properly packaged shipments will have accounted for the effects of weather and steps will have been taken to protect the package both inside and out.

Prevents Damage from Moisture

Protecting parts against moisture during shipping is extremely important. In addition to rain, packages can be exposed to moisture due to condensation buildup in trailers and shipping containers. When this occurs, parts can become warped, moldy, or riddled with rust. To reduce the risk moisture damage will occur, parts should be packaged accordingly.

How ISO Finishing Packages Parts

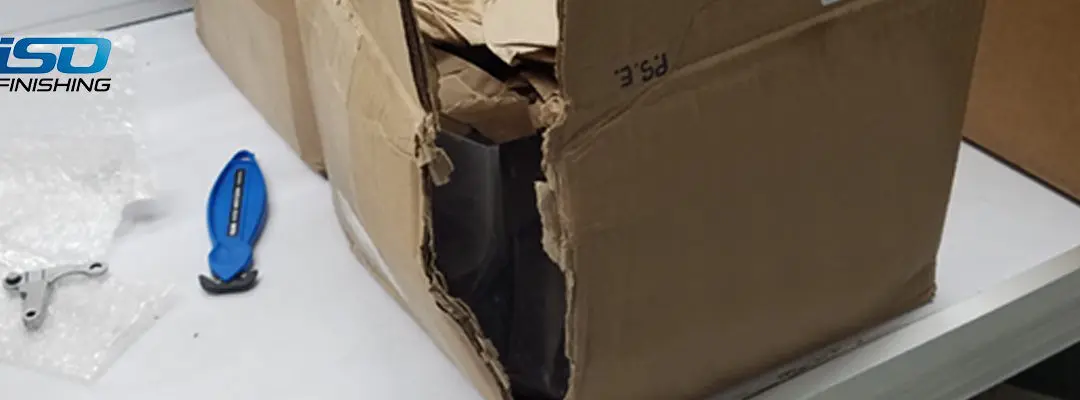

Unfortunately, some elements of the shipping process are beyond our control. From poorly handled packages to unsatisfactory environmental conditions, some things are unavoidable. However, there are measures ISO Finishing takes to ensure parts are protected.

When preparing shipments, the size and geometry of the part is examined to determine how it should be packaged for a safe delivery to the customer. Parts with sharp edges may cause damage to other parts during shipping. When necessary, parts sensitive to damage are packaged individually to reduce any risk. Packing materials are then used to further protect the parts from damage caused by external forces such as the stacking, dropping, and vibrating.

We also employ the use of Volatile Corrosion Inhibitors (VCI) for added protection when shipping metal components. VCIs are available in a variety of forms ranging from paper to films to wraps. These materials contain special elements to prevent corrosion caused by moisture buildup during shipping. VCIs release compounds inside the package, which then form a thin film on the surface of metal parts. This film is invisible and does not affect the physical properties of the metal. In fact, the parts can be used or have coatings applied right out of the package without further cleaning.

To learn more about ISO Finishing’s process or to request free sample processing, please contact our team at 1 (844) 623-7968.