What is a machining burr?

Machining burrs are the unwanted projections of material on machined parts. Any method of cutting or removing material, such shearing, machining metal, plastics, and rubber are used to create components and parts of machinery the most common methods in that process are welding, molding, casting, trimming, slitting or shearing. All these methods often result in the products having ragged, bumpy edges. These often sharp, raised bits and pieces that are still attached to the part are referred to as burrs.

Are there different types of burrs?

Yes, there are different types of burrs depending on the material and manufacturing methods used. The different types of burrs below require different types of deburring services:

Rollover Burr or Exit Burr

A roll over burr happens during the machining process when a part is being pierced, punched, parted, notched, or sheared. It is one of the more common types of burrs that occur. When the machine first engages the part, whether it’s being punched, sheared or notched, it pulls the material causing it to bend or rollover.

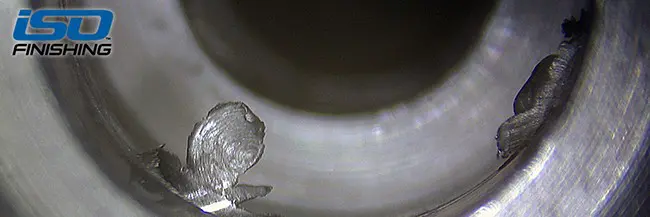

Tear burr

A tear burr is when the material on the machined part tears or deforms rather than sheared. This most commonly happens in the side-milling process. When the workpiece is torn some of the remaining torn portions are left on the workpiece and are called tear burrs.

Poisson Burr

A burr that occurs when the material bulges outwards or sideways when the machine tool applies a downward force to the part.

Cut-off Burr (or Breakout Burr)

This type of burr occurs when there is a separation of the work material before the cut is finished.

ISO Finishing specializes in the mass finishing of burr removal with vibratory and centrifugal barrel (high energy) machines. Vibratory deburring and finishing is the most common mass finishing method. It is much more efficient and economical than hand deburring and provides a very consistent part finishing process for mass part finishing. Centrifugal barrel finishing uses the same media as in the vibratory deburring process. The centrifugal processing can achieve superior surface finishing more quickly and without the use of chemicals due to the rapid rotation and centrifugal force on the media and parts.

ISO Finishing Deburring Services for Precision Manufacturing

ISO Finishing specializes in vibratory finishing, high energy polishing, and micro-precision surface improvement. Through our innovative finishing solutions and industry-leading delivery times, ISO Finishing has become the go-to finishing resource for Fortune 500 manufacturers to small business owners alike. Serving industry leaders in additive manufacturing, aerospace/aviation, defense/military, dental, firearm, injection molding, medical, OEM, and performance motorsport markets. ISO Finishing is known for quality metal finishing expertise on titanium, aluminum, stainless steel, carbon steel, brass, and copper. We also have the proven ability to offer customized finishes on plastic, rubber, silicone, and ceramic parts. ISO Finishing is committed to providing unsurpassed customer satisfaction by maintaining the highest quality finishing solutions.

Do you offer free sample processing?

Yes, we do! Just give us a call or fill out the Free Sample Request Form. You can send a few samples to finish. We will provide you with options and partner with you to help determine the best process needed for the surface finish your part requires.