Automotive Crankshaft Polishing

Creating more horsepower without adding weight is the ultimate goal of any engine design team, including Jayhawk Motorsports, the Formula SAE Team of the University of Kansas. For the Jayhawk build, ISO Finishing used a precise combination of media and additives. Utilizing the HZ-220 centrifugal barrel machine to remove all machining burrs, flatten all as-cast features, and isotropic polishing of the crankshaft surface to an Ra of 3µin. The resulting finish improved oil drainage, reduced fluid drag, reduced friction power losses, and improved overall mechanical efficiency. The Jayhawk Motorsports team was able to quantitatively measure a peak horsepower increase of over 8% when compared to the unpolished stock engine. Applying the same surface improvement techniques to suspension, transmission or any other mechanical components can improve wear resistance, increase reliability and lower overall life cycle costs. Learn more about Performance Motorsports component polishing.

Premium Hunting Blade

Throughout the course of a day it’s likely we use a knife several times. It is often underappreciated, and little thought goes into what it takes to manufacture it. It’s just there. Knives have evolved over the course of time and have become a product of the same technological innovations making the rest of life as we know it possible. In the premium hunting blade example shown, we took a two-step process to remove the heat treat scale and refine the edges in preparation for the final edge grind, polish and assembly. By using a segregated process in our centrifugal barrel machine, we were able to impart compressive stress to the component which increases surface uniformity and provides greater edge longevity. In cases where the cosmetic appearance is less critical, batch processing can be used to yield very similar results.

Machined Pistol Bolt

Mention of the word “Marksman” conjures images of a sharp shooter cutting a poker card in half to win a few dollars and bragging rights. Although the settings have changed, the resurgence in competitive shooting has taken the sport mainstream. Everyone from high school trap league shooters to fully sponsored and televised tactical pistol competitors have helped propel and expand its popularity. All shooters rely on the flawless performance of their firearms to win. Advances in materials and CNC machining methods have helped produce some of the most accurate firearm components ever, but these combined can only take the final part so far. In the heat-treated competition pistol bolt shown we used our centrifugal barrel machine with a combination of ceramic and porcelain media to remove the scale and any residual machining lines. We were able penetrate the deep internal wear areas and polish the entire part to a surface finish of 2Ra to allow maximum adhesion of DLC and other performance coatings to give the shooter the best firearm possible. Learn more about Firearm Surface Finishing

Injection Molded Firearm Lever

The lever action rifle is an icon of the American west and a testament to the reliability and simplicity of its design. While injection molding has made the manufacturing of this lever and thousands of other firearm components more precise and economical, removing the gating and die lines has remained an issue inherent with all firearm parts produced with this technology. In the sample shown here we were able to remove all residual imperfections, radius all edges and polish the overall surface finish to a mirror. We used a multiple step, segregated process using plastic and organic tumbling media to achieve the 2 Ra finish. The final fit and finish match the performance and aesthetic expectations of firearm enthusiasts and collectors alike. Learn more about Firearm Surface Finishing

Machined Brass Coupling

Many of today’s plumbing and industrial fluid transfer fittings are made from variety of brass and bronze alloys. Used primarily for their corrosion resistance, these copper alloys are also ideal materials for polishing, clear coating and chrome plating. For this project, we started with a 1.25” dia x 3” long precision machined fitting. We cut and polished the part, removing all of the tooling marks and machining burrs to prepare it for chrome plating.

316 Stainless Steel Investment Casting

Stainless steel has been the go-to metal in applications whenever corrosion is a concern. It is relatively hard so it also lends itself to applications where “wear and tear” is a design concern. In this example, we started with an investment casting, .25” thick and 3.25” diameter, with a surface Ra of 327. By starting with an aggressive ceramic media, followed with plastic and polishing media, we were able to achieve a final Ra of 7. These promotional marketing medallions will withstand the test of time.

Cast Aluminum Aftermarket Exhaust Cap

Castings are one of the most cost effective means of producing parts with complex geometries. An aftermarket automotive accessories manufacturer wanted a way to remove some of the casting inconsistencies and ease the edges on the overall profile on the aluminum castings. For these 6” x 6” x 12” custom exhaust caps we used multiple plastic medias to achieve a smooth, polished surface while maintaining the “rough” characteristics of the product.

Architectural Brass Railing Finials

Architects will often incorporate brass components when clients are looking for design features with a traditional, warm, highly reflective surface. In this particular example, a national architectural metals supplier was looking for a way to remove the oxidation from the forged brass birdcage baskets. We used the centrifugal barrel process with a media that would pass thru the part. All of the surfaces of the 2” diameter x 4” long component had the same high end luster to match the rest of the project.

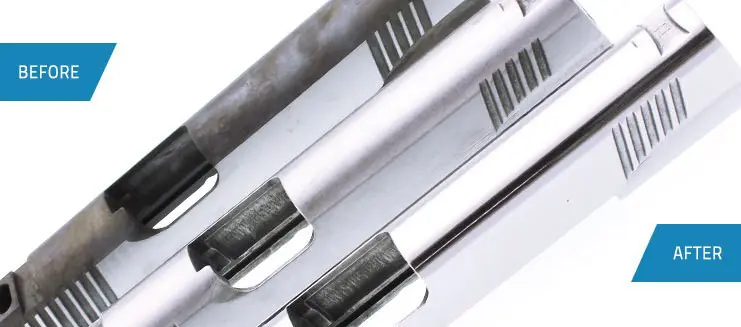

Cast and Machined Alloy Steel Handgun Slides

Many of todays’ firearms are manufactured by machining components produced by the investment casting or injection molding process. Parts produced by either means still require finishing to remove burrs and improve the surface quality. For these 1” x 1” x 8” high performance alloy steel handgun slides we combined the appropriate cutting and polishing media to provide the pre-plating finish required.

Cast 316 Stainless Steel Baby Spoons

Stainless steel is used almost exclusively in the manufacture of todays’ utensils and cutlery. Adjusting nickel, chromium and other trace elements allows the design of specific alloys designed to match each unique application. For these .25” x .75” x 6” custom baby spoons we were able to cut and polish the 316 stainless steel casting to a mirror surface ready for individual laser marking. We can also use the same approach and offer smooth, satin finishes for applications requiring a matte finish.