CEntrifugal Barrel Finishing Equipment

Mass Finishing Inc. Machines and Equipment

How It Works

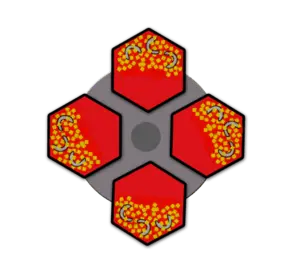

Centrifugal barrel finishing machines operate on the “Ferris Wheel” principle with a one-to-one ratio of barrel rotation to turret rotation. Each of the four barrels is loaded to roughly 50-80% full of media, parts, water, and compound. During operation, rotation of the turret creates a sliding force inside the barrel. This motion causes parts and media to contact each other in random or isotropic directions. The resulting finish is consistent across the entire surface of the part. MFI provides complete sample processing and stocks all required media and supplies.

One machine, Four Barrel Options

Two-Sided barrels

- Allows for use of dividers

- Heavy duty cam locks

Bolt-end Barrels

- Best for high pressure

- Removable polyurethane liner

Latched-End Barrels

- Largest capacity

- Snapping latches for quick lid removal

Half-size Barrels

- Light and easy to get in and out of machine

- Latches for quick lid removal

Available Options and Accessories

Parts and Media Separator

Make the media and part separation process simple with our free standing media separator. Dump full barrels on the vibratory screen and watch as the media and your parts separate.

Processing Table and Tank

Reduce the mess from the process with MFI’s processing table and sludge tank. Sediment from your tumbling process is collected and easily cleaned out.

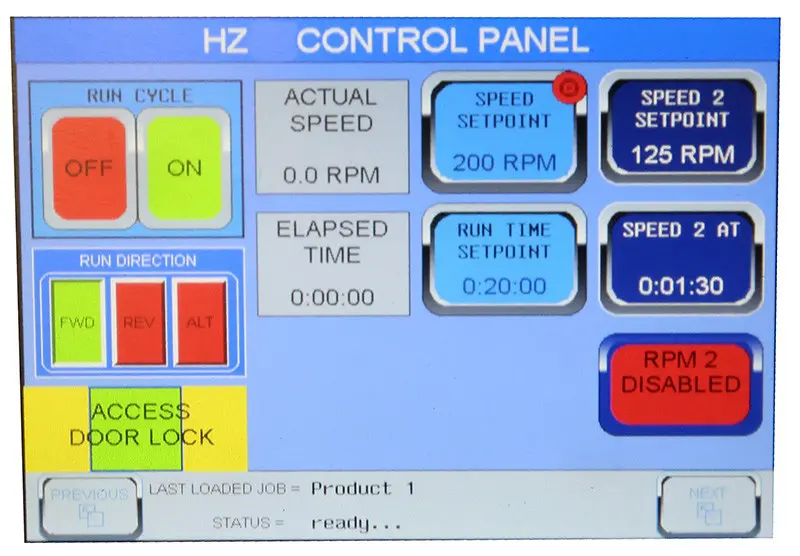

PLC Touchscreen Interface

Store processes as recipes in this PLC touchscreen interface. This unit replaces the analog cycle start buttons and allows for better monitoring of machine use and time.

Extra barrels

Dramatically reduce your downtime on the machine by purchasing a second set of barrels. The operator can load and unload while the machine is running.

Which MFI Product is right for you?

Let us help you solve your mass finishing needs. Along with MFI we take great pride in our reputation for helping our customers find the optimum finishing solutions for a variety of different industries, materials, production processes and product finishing specifications.